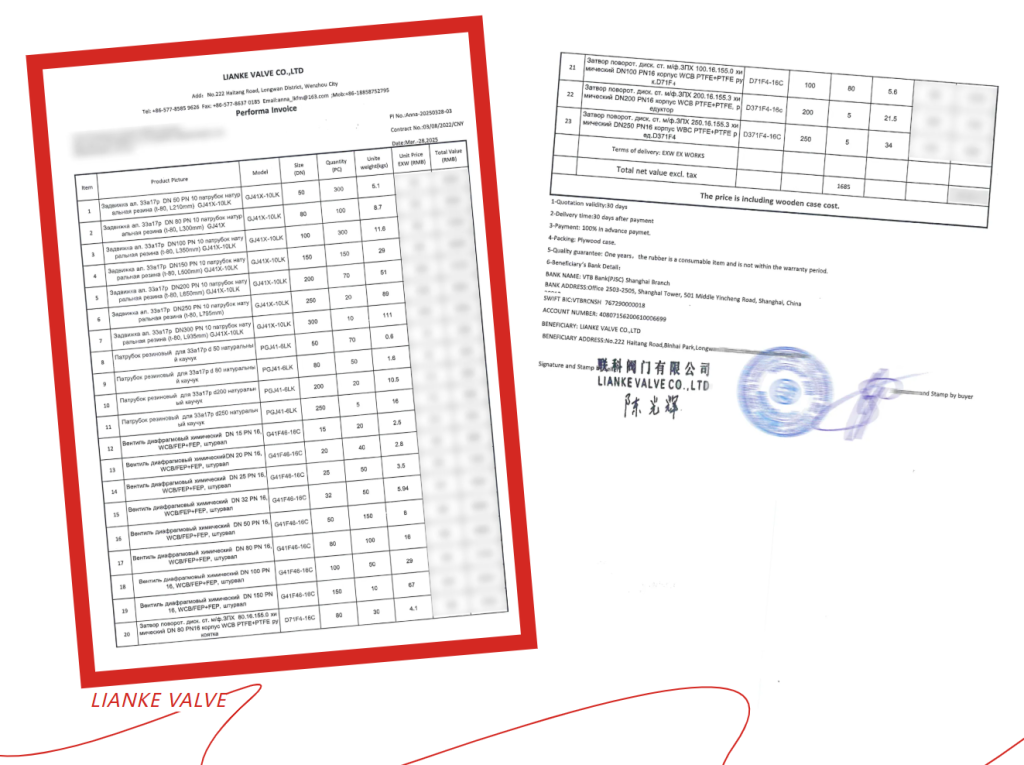

Our international business continues to thrive as we have recently signed a significant export order involving 1,685 units of pinch valves and fluorine-lined valves.

This successful deal is not only a testament to the long-term trust between both parties, but also a strong endorsement of Lianke’s reputation and brand strength in the global market.

As a national high-tech enterprise with nearly 40 years of expertise in the design and manufacturing of pinch valves, industrial strainers, and PTFE/PFA-lined valves, Lianke has always adhered to the core philosophy of “Craftsmanship Quality, Innovative Service.”

Our products are widely recognized by customers worldwide for their:

The client involved in this deal is a long-term partner who has chosen Lianke repeatedly, a strong reflection of the trust and satisfaction we earn from the international market.

This newly secured order is not only a recognition of Lianke’s product quality, but also a result of mutual trust and long-standing collaboration.

Looking ahead, we will continue to:

All in support of helping our customers achieve sustainable business growth.

We warmly welcome more partners from around the world to join us and seize opportunities for shared success!

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]