Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards.

In this article, we’ll walk through every step of the liquid filtration process, explain the role of municipal water treatment systems, and help you understand how water travels from its natural source to your faucet. Whether you’re new to the topic or just need a refresher, this guide breaks it all down in simple terms.

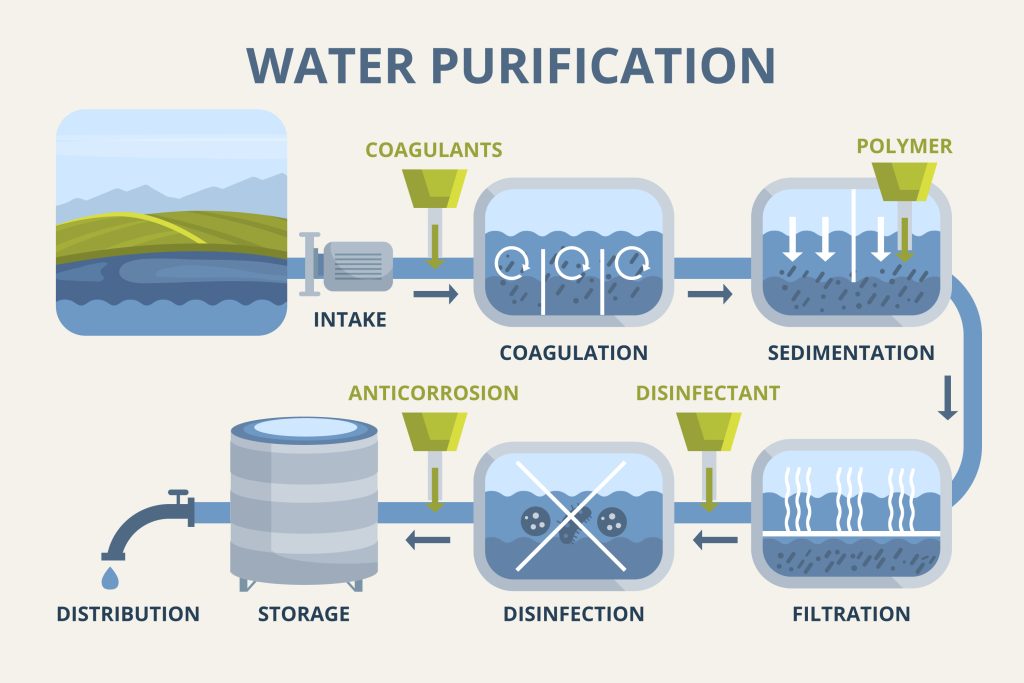

Municipal water treatment is the process of cleaning and purifying water sourced from lakes, rivers, or underground wells so it’s safe for public use. This water goes through a water processing plant or water refinery plant before it reaches homes and businesses.

The process begins at the water filter plant with chemical addition. Special chemicals called coagulants (like aluminum sulfate or ferric chloride) are added to raw water. These chemicals react with particles in the water to form clumps known as “floc.”

This step is essential to make particles heavy enough to settle in the following stages. Without coagulants, tiny dirt and organic matter would stay suspended and be harder to remove.

In this phase, the water enters a treatment unit called a flocculator. Here, it is gently mixed so the floc particles can grow larger and heavier, making it easier for them to separate from the water later on.

Positively charged chemicals bind with negatively charged particles in the water, helping form larger clumps. These clumps are called “floc” and are a key part of preparing water for sedimentation.

Once the floc forms, water moves into a clarifier or sedimentation basin. Here, gravity does its job. The heavy floc settles at the bottom of the tank. This sludge is later removed and sent to a disposal pond or sedimentation tank.

Clarified water, now free of large particles, flows to the next stage. This step is vital to avoid overloading filters in the following phase.

At this point, the clearer water enters filters made from layers of sand, gravel, or activated carbon. These filters trap smaller particles that didn’t settle out during clarification.

Activated carbon is especially effective in improving taste and odor. It also removes organic compounds and some chemicals. This phase is crucial in any filter plant, as it ensures the water is as physically clean as possible.

Filtered water still may contain harmful microorganisms like bacteria or viruses. Disinfection is the final barrier in the water treatment process.

Most water refinery plants use chlorine-based chemicals like chlorine dioxide or hypochlorite. These kill pathogens without affecting water quality. Chlorine levels are closely monitored to balance safety and taste.

Municipal water treatment systems use different types of filters depending on the condition of the water and the desired purity level.

This method uses mechanical means to trap solids from water. It includes:

For high-purity applications, membrane filters are used:

Ultrafiltration and microfiltration are usually done before RO to reduce the load on the system.

Municipal water isn’t just for drinking. It also supports:

Clean water is essential not only for health but also for economic activity. Water treatment plants make this possible every day.

Even with treatment, it’s essential to be aware of potential contaminants:

Municipal water systems are designed to test and treat these threats, but testing is an ongoing process.

Understanding the liquid filtration process for municipal water treatment plants helps us appreciate the complex systems behind something as simple as turning on a tap. Each step plays a vital role in protecting public health and ensuring water reliability.

At Клапан Lianke, we support water treatment efforts by offering reliable industrial filtration solutions. Explore our фильтры to improve your municipal or industrial water processing plant today.

Need help selecting the right filtration solution? Contact our experts at Клапан Lianke.

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]