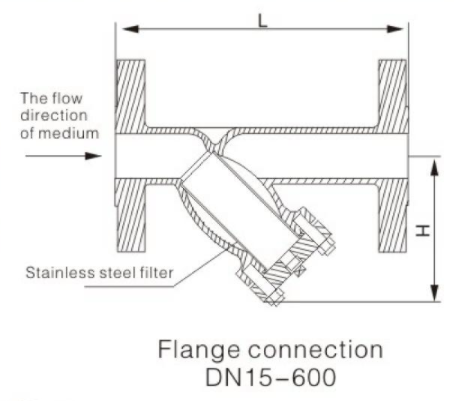

Y-type Strainer is an indispensable filter device in the pipeline system of conveying media.

It is installed at the inlet end of pressure reducing valve, pressure relief valve, fixed level valve or other equipment to remove impurities in the media to protect the normal use of valves and equipment.

The characteristics include advanced structure, low resistance, convenient blowdown and so on.

Its applicable media can be water, oil, gas. Generally, the water network is 18 to 30 mesh, the ventilation network is 10 to 100 mesh, and the oil network is 100 to 480 mesh。

Main parts and materials

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Screen | SS304 | SS304 | SS304L | SS316L | SS316L |

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Gasket | PTFE、NBR、Metal Wound Graphite | ||||

| Filter Fineness | 10Mesh ~ 400Mesh | ||||

| Flange Standard | JIS、ASME、DIN、BS、GB | ||||

| Pressure | 0.6Mpa ~ 6.3Mpa、150LB ~ 600LB | ||||

The main connection size

| PRESSURE | 16C | 16P | 25C | 25P | 150LBC | 150LBP | ||||||

| SIZE | L | H | L | H | L | H | L | H | L | H | L | H |

| DN15(1/2″) | 134±2 | 60 | 134±2 | 60 | 134±2 | 60 | 134±2 | 60 | 134±2 | 60 | 134±2 | 60 |

| DN20(3/4″) | 142±2 | 70 | 142±2 | 70 | 142±2 | 70 | 142±2 | 70 | 142±2 | 70 | 142±2 | 70 |

| DN25(1″) | 152±2 | 70 | 152±2 | 70 | 152±2 | 70 | 152±2 | 70 | 152±2 | 70 | 152±2 | 70 |

| DN32(1-1/4″) | 183±2 | 75 | 168±2 | 75 | 183±2 | 75 | 168±2 | 75 | 182±2 | 75 | 166±2 | 75 |

| DN40(1-1/2) | 200±2 | 90 | 200±2 | 90 | 200±2 | 90 | 200±2 | 90 | 200±2 | 90 | 200±2 | 90 |

| DN50(2″) | 214±2 | 105 | 216±2 | 105 | 216±2 | 105 | 216±2 | 105 | 217±2 | 105 | 217±2 | 105 |

| DN65(2-1/2″) | 250±2 | 150 | 252±2 | 150 | 251±2 | 150 | 252±2 | 150 | 250±2 | 150 | 252±2 | 150 |

| DN80(3″) | 285±2 | 175 | 282±2 | 175 | 286±2 | 175 | 282±2 | 175 | 284±2 | 175 | 282±2 | 175 |

| DN100(4″) | 305±2 | 200 | 309±2 | 200 | 303±2 | 200 | 310±2 | 200 | 310±2 | 200 | 311±2 | 200 |

| DN125(5″) | 350±2 | 205 | 348±2 | 205 | 353±2 | 205 | 352±2 | 205 | 353±2 | 205 | 354±2 | 205 |

| DN150(6″) | 385±2 | 260 | 388±2 | 260 | 388±2 | 260 | 400±2 | 260 | 388±2 | 260 | 393±2 | 260 |

| DN200(8″) | 485±2 | 300 | 470±2 | 300 | 485±2 | 300 | 470±2 | 300 | 480±2 | 300 | 473±2 | 300 |

| DN250(10″) | 552±2 | 380 | 540±2 | 380 | 552±2 | 380 | 545±2 | 380 | 552±2 | 380 | 538±2 | 380 |

| DN300(12″) | 606±2 | 410 | 643±2 | 410 | 641±2 | 410 | 653±2 | 410 | 641±2 | 410 | 643±2 | 410 |

| DN350(14″) | 672±3 | 480 | 683±3 | 480 | 668±3 | 480 | 680±3 | 480 | 668±3 | 480 | 682±3 | 480 |

| DN400(16″) | 755±3 | 540 | 755±3 | 540 | 758±3 | 540 | 755±3 | 540 | 763±3 | 540 | 755±3 | 540 |

| DN450(18″) | 850±3 | 580 | 850±3 | 580 | 853±3 | 580 | 853±3 | 580 | 853±3 | 580 | 853±3 | 580 |

| DN500(20″) | 895±3 | 645 | 900±3 | 645 | 895±3 | 645 | 900±3 | 645 | 895±3 | 645 | 900±3 | 645 |

| DN600(24″) | 1060±6 | 950 | 1060±6 | 950 | 1060±6 | 950 | 1060±6 | 950 | 1060±6 | 950 | 1060±6 | 950 |

| NOTE:C=WCB, P=SS | ||||||||||||

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

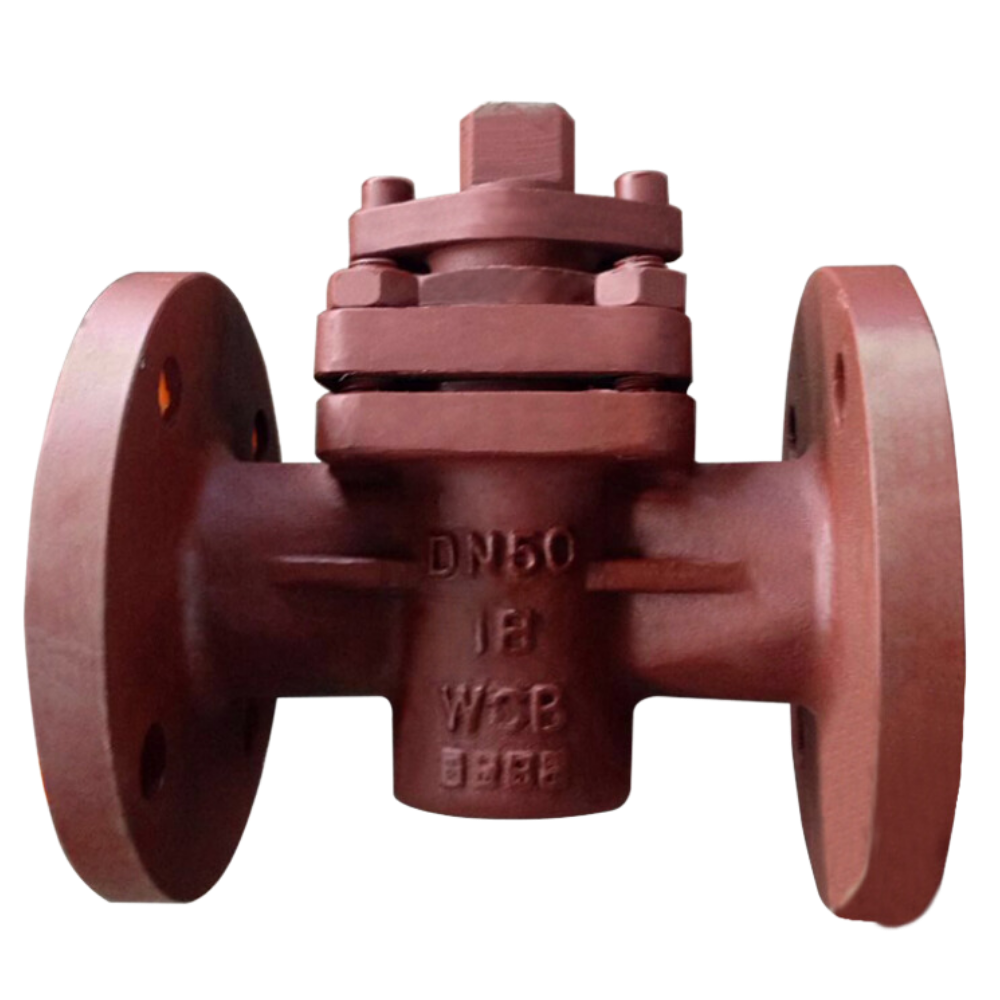

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

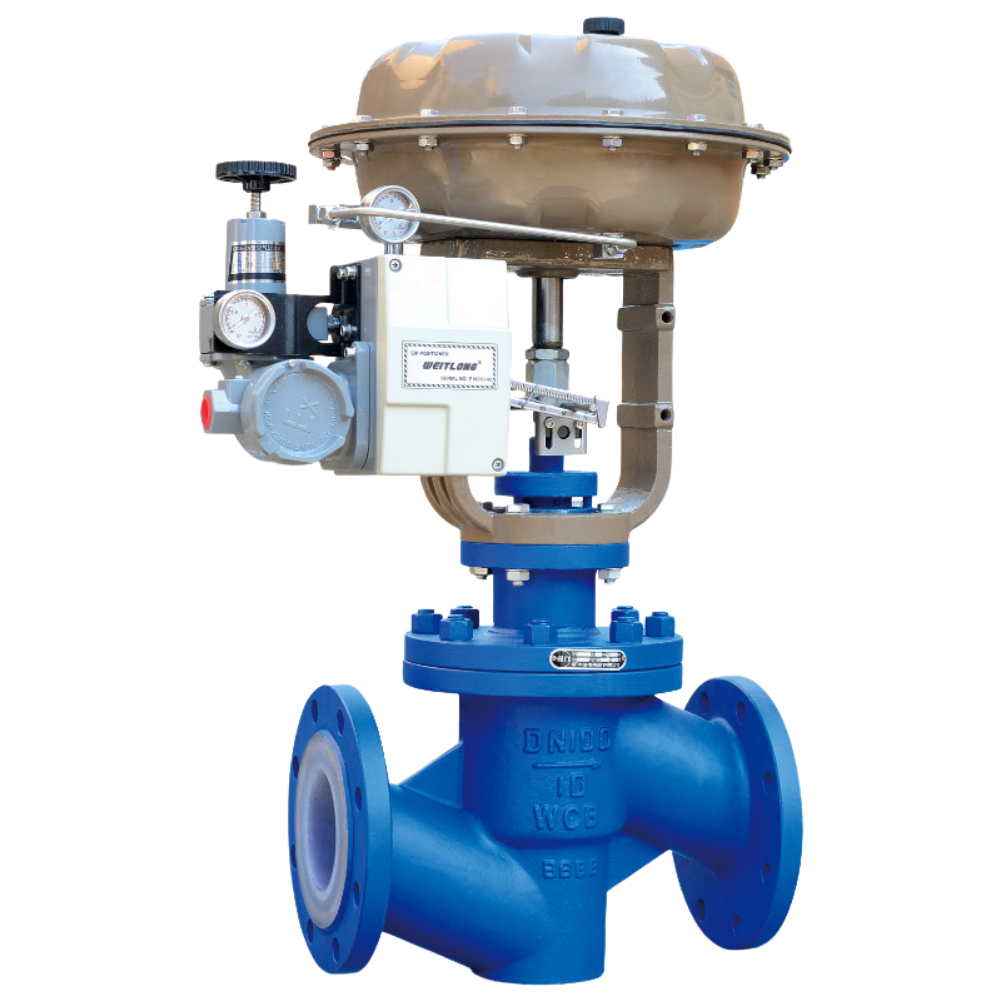

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]