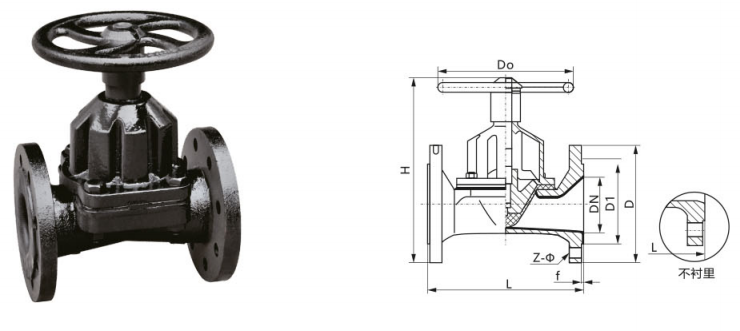

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path.

The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, such as in chemical processing and water treatment.

Main parts and materials

| Name/Material | CI | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | CI | WCB | CF8 | CF3 | CF8M | CF3M |

| Diaphragm | EPDM/NR/IIR | EPDM/NR/IIR | EPDM/NR/IIR | EPDM/NR/IIR | EPDM/NR/IIR | EPDM/NR/IIR |

| Lined | EPDM/NR/IIR | |||||

| Seat | EPDM/NR/IIR | |||||

| Bolt/Nut | B7/2H | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

Technical Specification

| Design&Manufacture Standard | GB12239 | GB12239 | ||

| FTF Dimension Standard | BS5156 | BS5156 | ||

| Flange standard | BS4504 | ASME B16.5 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN25~DN300 | 1”~12” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | EPDM:-29℃~110℃, NR:-29℃~80℃, IIR:-29℃~110℃ | |||

| Applicable Medium | General corrosive medium and abrasive material | |||

The main connection size

| DN (mm | PNS (Inch) | Normal pressure (Mpa) | Working pressure (Mpa) | L | D | D1 | Z-Φd | f | H | Do |

| 20 | 3/4 | 1.0 | 1.0 | 117 | 105 | 75 | 4-14 | 2 | ||

| 25 | 1 | 127 | 115 | 85 | 4-14 | 2 | 146 | 120 | ||

| 32 | 1-1/4 | 148 | 140 | 100 | 4-18 | 2 | 152 | 120 | ||

| 40 | 1-1/2 | 159 | 150 | 110 | 4-18 | 2 | 152 | 120 | ||

| 50 | 2 | 190 | 165 | 125 | 4-18 | 2 | 163 | 120 | ||

| 65 | 2-1/2 | 216 | 185 | 145 | 4-18 | 2 | 205 | 230 | ||

| 80 | 3 | 254 | 200 | 160 | 818 | 2 | 220 | 230 | ||

| 100 | 4 | 305 | 220 | 180 | 8-18 | 2 | 262 | 280 | ||

| 125 | 5 | 0.6 | 356 | 250 | 210 | 8-18 | 3 | 290 | 280 | |

| 150 | 6 | 406 | 285 | 240 | 8-22 | 3 | 368 | 363 | ||

| 200 | 8 | 521 | 340 | 295 | 8-22 | 3 | 410 | 363 | ||

| 250 | 10 | 0.4 | 635 | 395 | 350 | 12-22 | 3 | 559 | 483 | |

| 300 | 12 | 749 | 445 | 400 | 12-22 | 3 | 625 | 576 |

Straight-through diaphragm valves allow fluid to flow in both directions without obstruction. This makes them useful for different applications as they can handle changes in flow direction without issues.

These valves create a strong seal when closed, greatly reducing the chance of leakage. This is important in applications where preventing fluid loss is critical, especially when handling hazardous or corrosive substances.

The design of straight-through diaphragm valves simplifies maintenance. The diaphragm can be replaced without removing the entire valve from the pipeline, which reduces downtime and maintenance costs.

The unobstructed flow path in these valves results in a low pressure drop across the valve. This enhances system efficiency, particularly in high-flow applications, as it minimises energy loss.

Straight-through diaphragm valves work well with dirty or contaminated media. The straight flow passage helps prevent clogging, making them suitable for handling slurries, powders, and other thick fluids.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

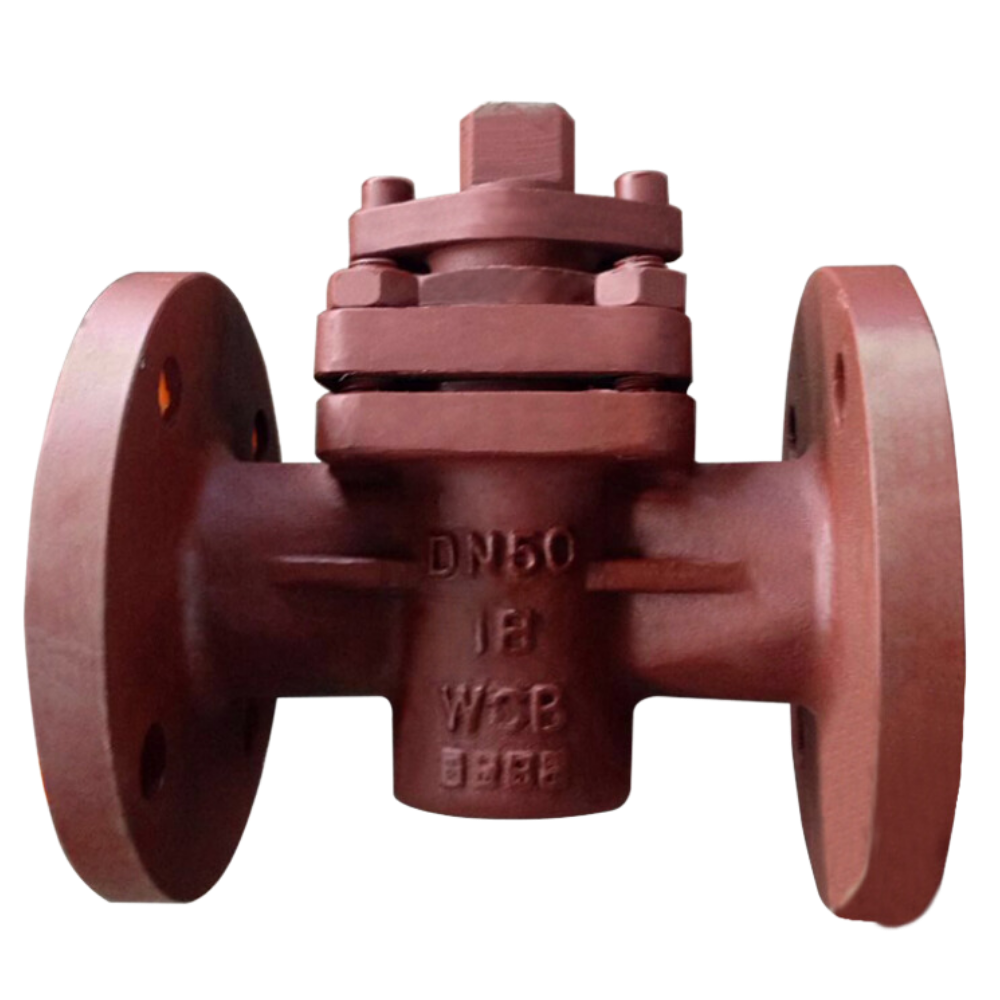

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

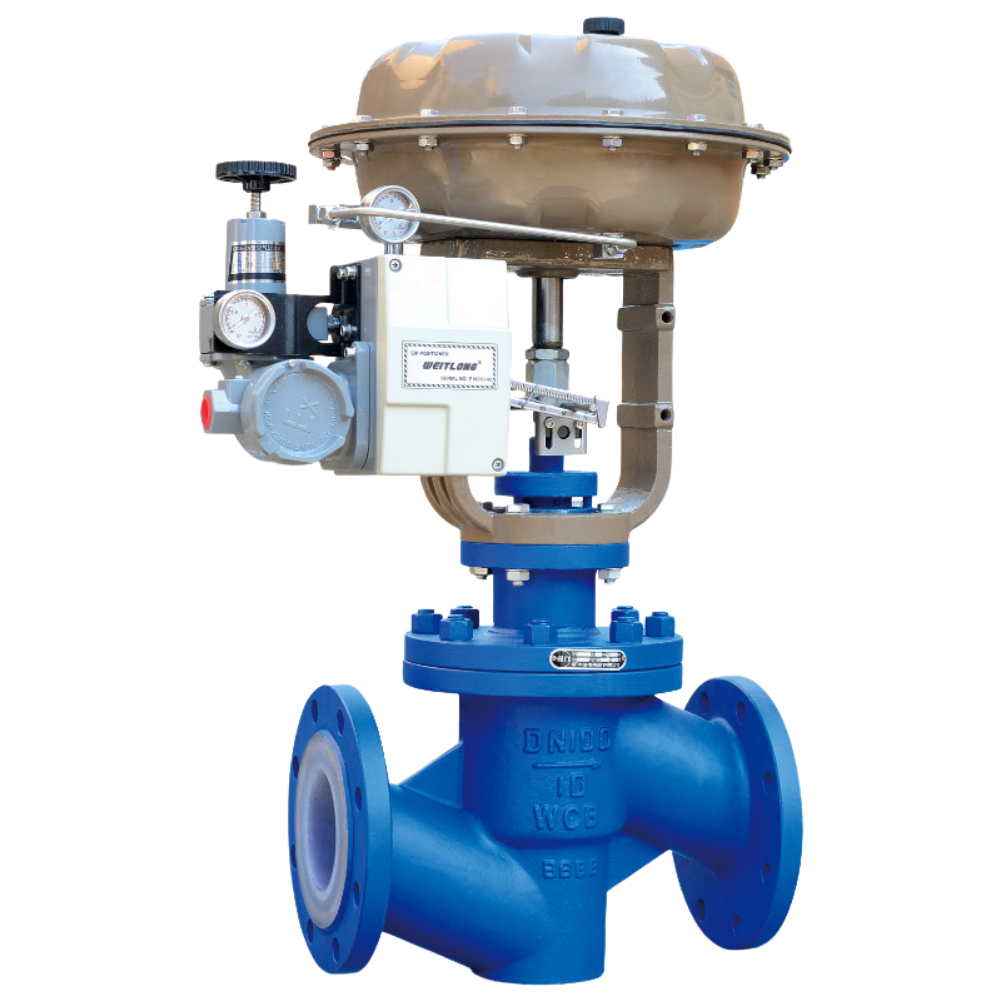

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]