The Pneumatic Stainless Steel Ball Valve (models Q41/341/641/941F/H/Y) is designed for efficient fluid control in various industrial applications. This valve utilizes a spherical closure element (the ball) that rotates around its axis to regulate the flow of liquids and gases.

Hard Seal V-Type Ball Valve

Multi-Pass Ball Valve

Pneumatic ball valves can be categorized based on their driving modes:

Manual Ball Valve: Operated manually through a handle or lever for straightforward applications.

Pneumatic Ball Valve: Operated using compressed air, providing rapid actuation.

Electric Ball Valve: Controlled by electric actuators for automated systems.

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Ball/Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Seat | PTFE / RPTFE/PPL | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Design&Manufacture Standard | GB/T12237 | API 6D |

| FTF Dimension Standard | GB/T12221 | ASME B16.10 |

| Flange standard | HG/T20592 | ASME B16.5 |

| Inspection & Test Standard | HG/T13927 | API 598 |

| DN (mm | L | D | D1 | D2 | b | Z-Φd | H | W |

| Q41F-16C Q41F-16P Q641F-16C Q641F-16P BQ41F-16C BQ941F-16P | ||||||||

| 15 | 130 | 95 | 65 | 45 | 14 | 4φ14 | 78 | 130 |

| 20 | 130/140 | 105 | 75 | 55 | 14 | 4φ14 | 84 | 130 |

| 25 | 140/150 | 115 | 85 | 65 | 14 | 4φ14 | 95 | 160 |

| 32 | 165 | 135/140 | 100 | 78 | 16 | 4φ18 | 150 | 160 |

| 40 | 165/180 | 145/150 | 110 | 85 | 16 | 4φ18 | 150 | 180 |

| 50 | 203/200 | 160/165 | 125 | 100 | 16 | 4φ18 | 170 | 200 |

| 65 | 222/220 | 180/185 | 145 | 120 | 18 | 4φ18 | 195 | 240 |

| 80 | 241/250 | 195/200 | 160 | 135 | 20 | 8φ18 | 215 | 240 |

| 100 | 305/280 | 215/220 | 180 | 155 | 20 | 8φ18 | 250 | 280 |

| 125 | 356/320 | 245/250 | 210 | 185 | 22 | 8φ18 | 265 | 300 |

| 150 | 394/360 | 280/285 | 240 | 210 | 24 | 8φ23 | 270 | 300 |

| 200 | 400/457 | 335/340 | 295 | 265 | 26 | 12φ23 | 330 | 350 |

| 250 | 533 | 405 | 355 | 320 | 30 | 12φ26 | 450 | 400 |

| 300 | 610 | 460 | 410 | 375 | 30 | 12φ26 | 540 | 500 |

Corrosion Resistance

Pneumatic stainless steel ball valves resist corrosion, making them suitable for environments with harsh fluids or gases. The use of stainless steel ensures durability and reduces the likelihood of valve failure.

Shut-Off Capabilities

These valves provide reliable shut-off, thanks to their design that creates a tight seal when closed. This feature helps minimise leakage and ensures safety in critical applications.

Quick Operation

Pneumatic ball valves can be opened or closed with a simple quarter turn, allowing for fast actuation. This quick response is useful in situations requiring immediate flow control or emergency shut-off.

Low Maintenance

The straightforward design of pneumatic stainless steel ball valves, which has fewer moving parts than other types, leads to lower maintenance needs. With proper installation and care, these valves can last a long time, reducing downtime.

Versatile Applications

Pneumatic stainless steel ball valves are suitable for various applications across different industries, including chemical processing and food production. They can handle liquids, gases, and slurries, making them a practical choice for many fluid control systems.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

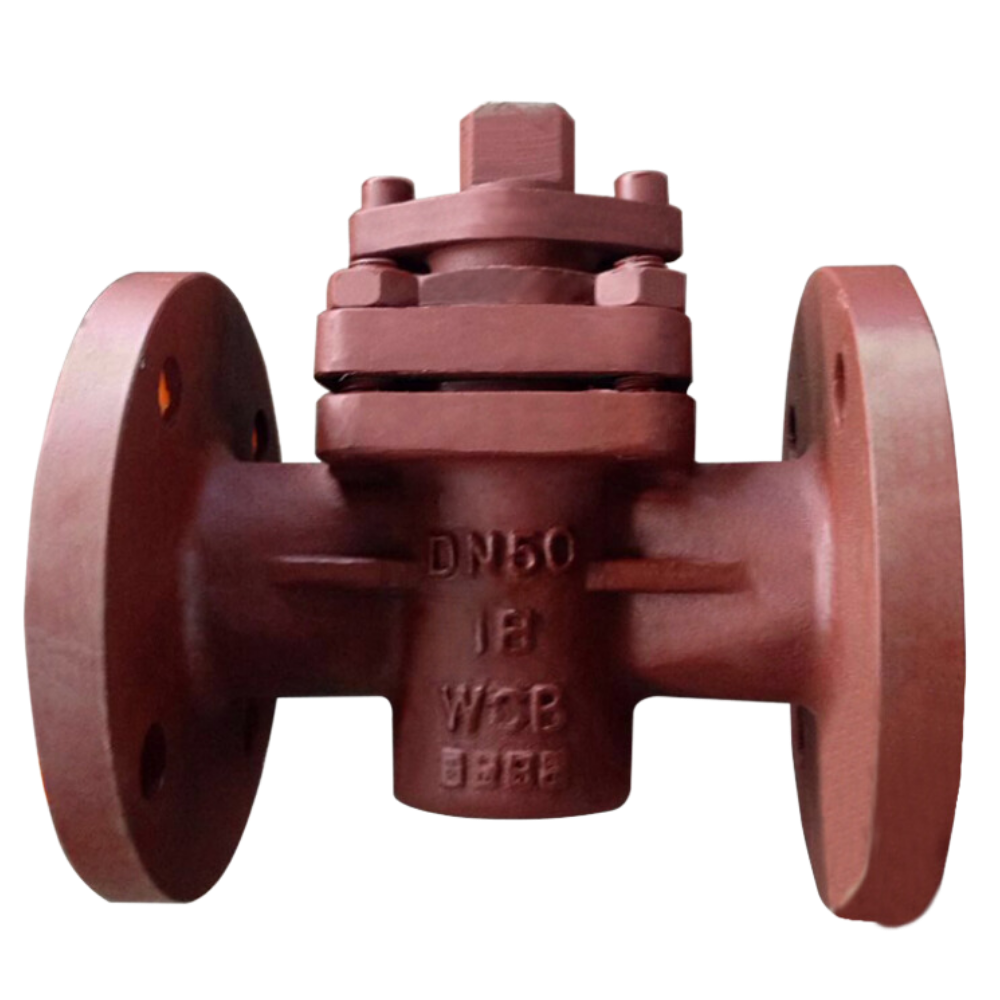

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

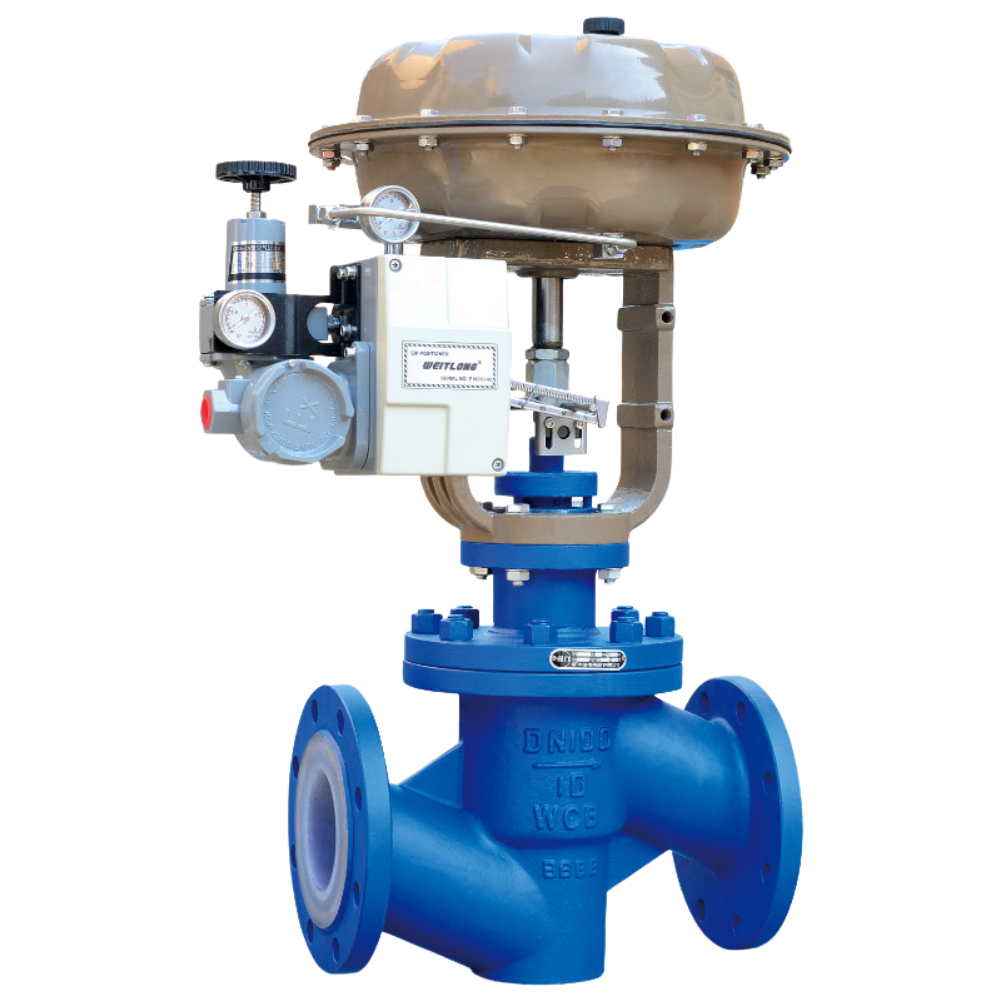

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]