Welding pneumatic pinch valves are 2/2-way valves that utilize pressurized air to open or close the valve, effectively managing the flow of corrosive, abrasive, or granular media, such as soldering agents. These valves are integral to creating the protective atmosphere required for submerged welding, ensuring that the welding process is efficient and effective

Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc.

when rotate the handle clockwise, valve stem drive the splint and compress sleeving to close valve, conversely, open the valve. So splint under the pull rod upper and downer to complete the work, because of the rubber sleeve can not sustain heavy strength, so when close it, operator feel a little collide is be ok, forbid to use other tools;

This valve can install on the pipe for free, no fluent direction limit, long term usage, if there is abrasion or leaks, just to remove the valve to replace a new valve core, the valve can use for a long time for economical and practical.

A.Could install it in any part of pipe and don’t limit of the medium flow direction.

B.Low maintenance cost, don’t need change the seat of valve, sealing material etc, only need change the rubber of sleeving.

A.Pinch valves can be used for On/Off, as well as throttling services

B.Pinch valves are ideal for on/off services because of their straight through design that allows for uninhibited flow

C.Straight through designs also have very little pressure drop between the inlet and outlet.

D.The effective throttling range of a pinch valve is usually between 10% and 95% of the rated flow capacity

E.Low maintenance

F.Low weight and easy operation

G.Easy changing the rubber sleeving and don’t need stock other parts except the rubber sleeving.

| Rubber quality | Application examples | Temperature range | Typical media |

| EPDM | Chemical applications: Applicable to 75% of all industrial chemical applications. | -40℃ – +110℃ | Concentrated and oxidiziing chemicals. |

| NR | High wear applications. | -40℃ – +80℃ | Abrasive materials, diluted acids, alkali & chemicals. |

| NBR | Applications involving oils, fats and hydrocarbon. | -30℃ – +100℃ | Oil, fats, fuels hydrocarbon, lubricants. |

| CR | Special-purpse chemical application: Resilient to ozone and averse weather | -40℃ – +100℃ | Chemicals, acids, several solvents, aliphatic oils, fats, lubricants |

| IIR | Special-purpse chemical application: Impermeable to gas | -40℃ – +100℃ | Concentrated and acidic chemicals, vegetable oil. |

| Name | Material |

| Body | Cast steel, Stainless steel |

| Sleeve | NR, EPDM, NBR, CR, IIR |

| Stem | Carbon steel, Stainless steel, Alloy steel |

| Pinch rod | Ductile iron |

| Side guide rod | Carbon steel, Stainless steel, |

| Hand wheel | Cast iron |

| Acceptable other special requirements of the material | |

| DN | PN(Bar) | L | D | K | Z-ɸ |

| 32 | 1-16 | 140 | 140 | 100 | 4-18 |

| 40 | 1-16 | 145 | 150 | 110 | 4-18 |

| 50 | 1-16 | 165 | 165 | 125 | 4-18 |

| 65 | 1-16 | 165 | 185 | 145 | 8-18 |

| 80 | 1-16 | 170 | 200 | 160 | 8-18 |

| 100 | 1-16 | 220 | 220 | 180 | 8-18 |

| 150 | 1-10 | 340 | 285 | 240 | 8-22 |

| 200 | 1-6 | 445 | 340 | 295 | 8-22 |

Our Welding pneumatic pinch valve offers a wide range of material choices to suit your specific needs:

The welding pneumatic pinch valve operates using pressurized air to open and close the valve. When pressurized air is applied, the valve compresses the rubber sleeve, effectively shutting off the flow of soldering agents. Releasing the pressure allows the sleeve to return to its original shape, enabling unrestricted flow.

Operators should avoid using excessive force when closing the valve, as the rubber sleeve has a limited bearing capacity. A slight resistance is normal; however, overexertion can lead to damage.

It is essential to periodically check the valve for wear on the rubber sleeve and other components to ensure optimal performance and prevent leaks.

The welding pneumatic pinch valve can be installed in various configurations within the pipeline, with no restrictions on flow direction. This adaptability simplifies integration into existing systems.

The valve is designed for straightforward maintenance, allowing for quick replacement of the rubber sleeve without extensive disassembly. This minimizes downtime and reduces maintenance costs.

The welding pneumatic pinch valve is suitable for controlling the flow of soldering agents in submerged welding processes, as well as handling slurries and granular materials in other industrial settings with a proven ability to withstand high-cycle operations (up to 450-600 cycles per day).

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

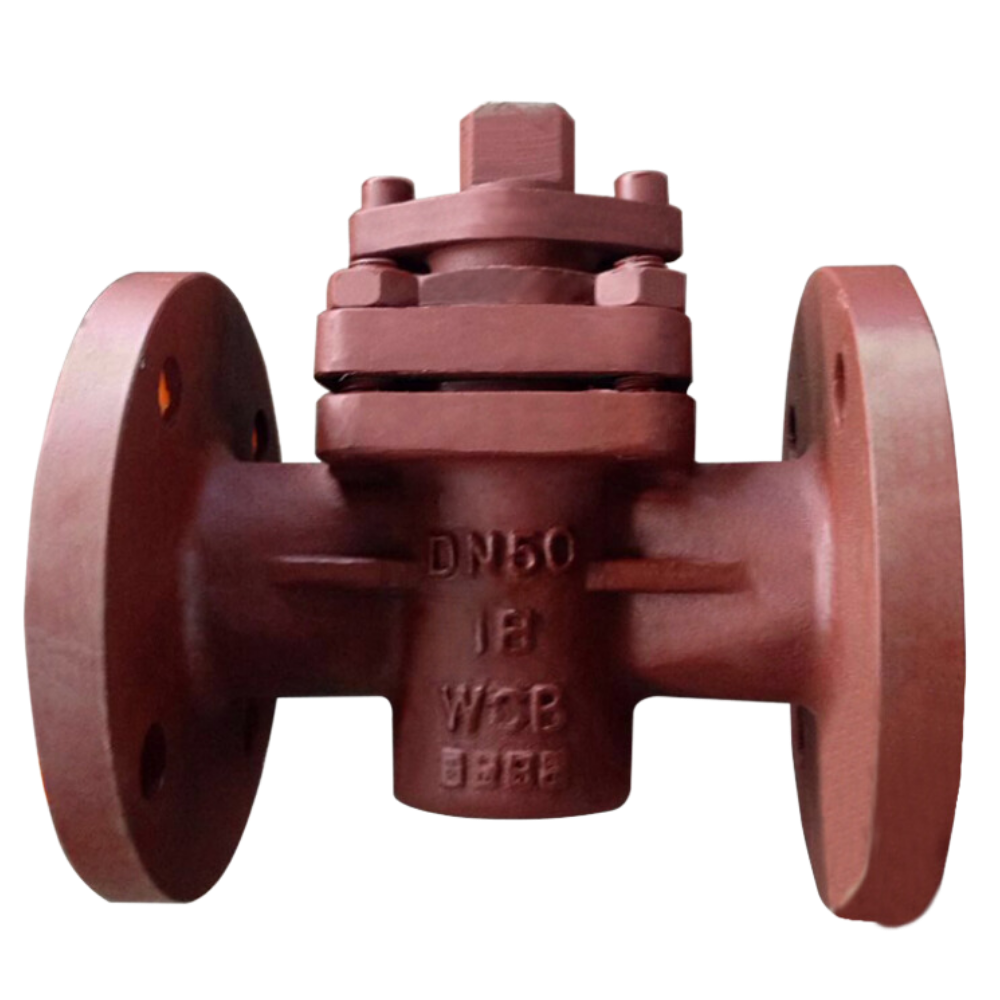

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

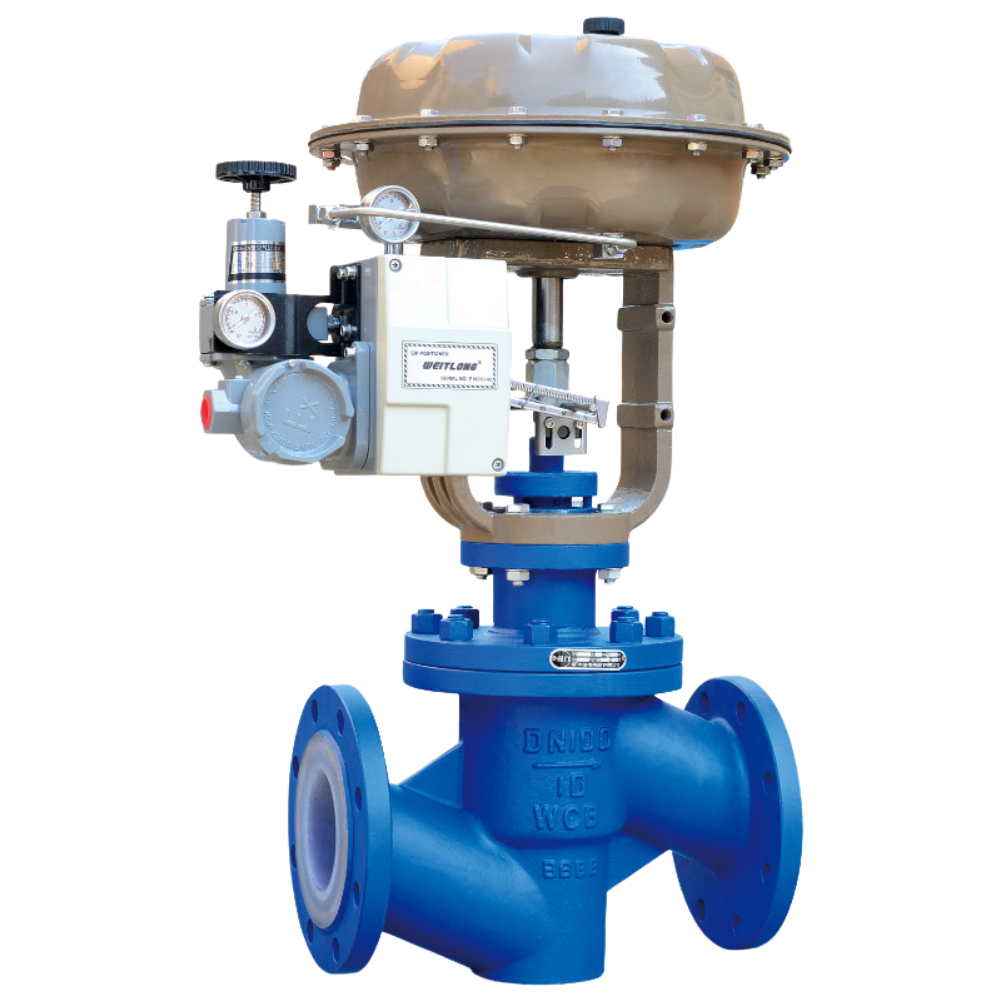

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]