A Y-type strainer removes debris and solid particles from liquids, gases, or steam in pipelines, protecting pumps, valves, and other equipment from damage. The strainer is named after its “Y” shape, which contains a mesh or perforated screen.

It allows fluid to pass through while trapping unwanted particles, which can be removed by cleaning the screen. Commonly used in water treatment, chemical processing, and HVAC systems, it helps ensure smooth operation and prevent blockages.

Main parts and materials

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Screen | PTFE | PTFE | PTFE | PTFE | PTFE |

| Lined | FEP / PFA / PO / PTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Fineness : 10Mesh ~ 100Mesh | |||||

Technical Specification

| Design&Manufacture Standard | GB/T12234 | API 6D | ||

| FTF Dimension Standard | HG/T3704, GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN25~DN300 | 1”~12” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

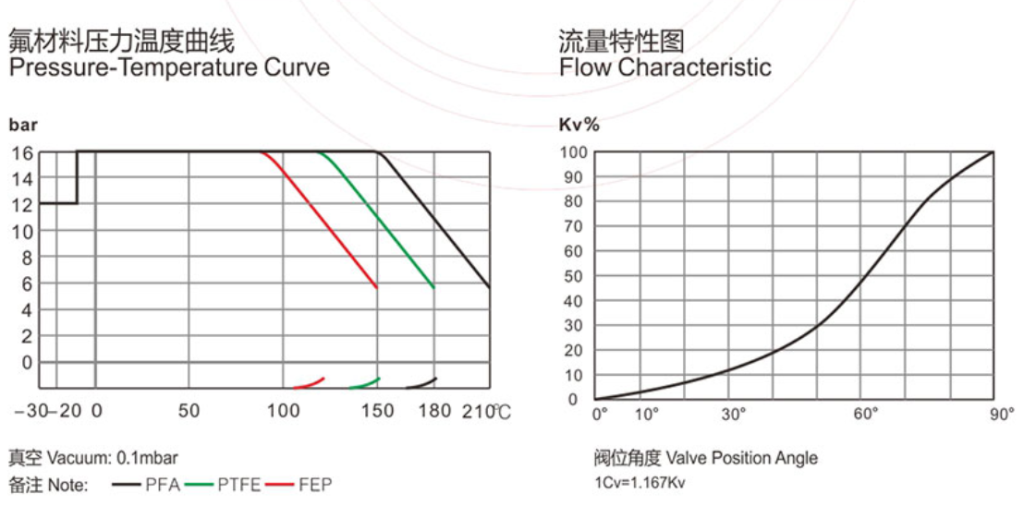

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

| Design&Manufacture Standard | GB/T12235 | API 6D | ||

| FTF Dimension Standard | HG/T3704, GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN15~DN350 | 1/2”~14” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

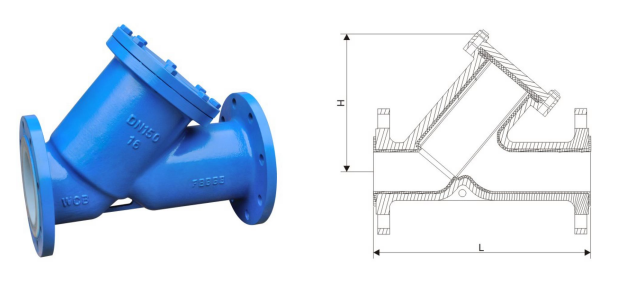

The main connection size

| DN (mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 165 | 185 | 200 | 230 | 295 | 315 | 355 | 405 | 480 | 605 | 680 | 780 |

| H | 115 | 115 | 145 | 165 | 175 | 205 | 230 | 285 | 315 | 400 | 430 | 470 |

Fluorine-lined Y-type filter is a new type of filter product developed by our factory based on the advantages of filters and fluorine plastic-lined valves according to customer requirements.This product is suitable for: various concentrations of hydrochloric acid, sulfuric acid, hydrofluoric acid, aqua regia, nitric acid, various organic acids, strong alkalis, strong oxidants or concentrated dilute acids, various organic solvents and other highly corrosive media except molten alkali metals, elemental gases and aromatic hydrocarbons (Note: the applicable media of different lining materials are different).The shell material of this product is carbon steel lined with fluorine plastic, and the filter material is F46, F4 and other materials.This product has the advantages of strong corrosion resistance, high filtration efficiency, and easy maintenance.

It effectively traps and removes debris from the flow, protecting downstream equipment from damage and ensuring smooth operation.

The Y-shape allows for installation in tight spaces, making it suitable for systems with limited room for larger filtration devices.

Y-type strainers can be installed in both horizontal and vertical pipelines, providing flexibility in system design.

The strainer can be easily cleaned by removing the screen, reducing downtime and maintenance efforts.

Y-type strainers are typically built from robust materials, making them resistant to wear and capable of handling high-pressure applications.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

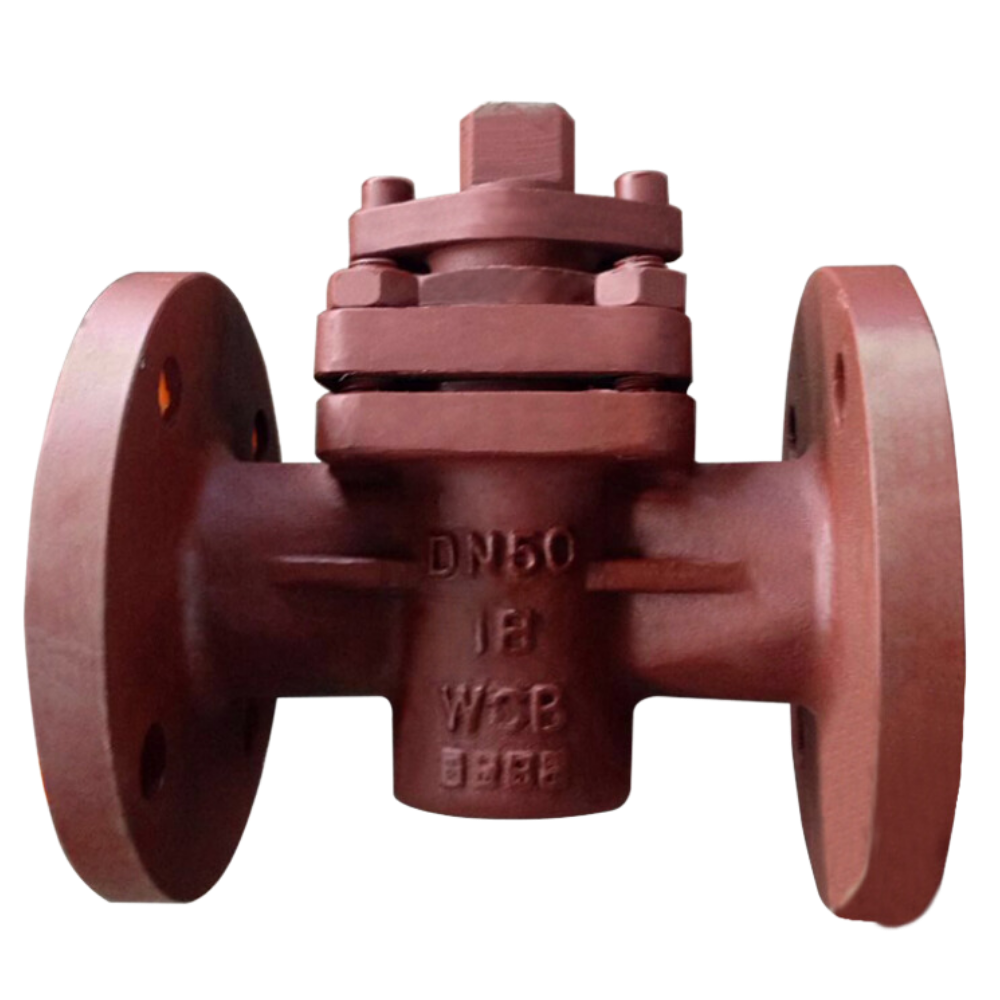

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

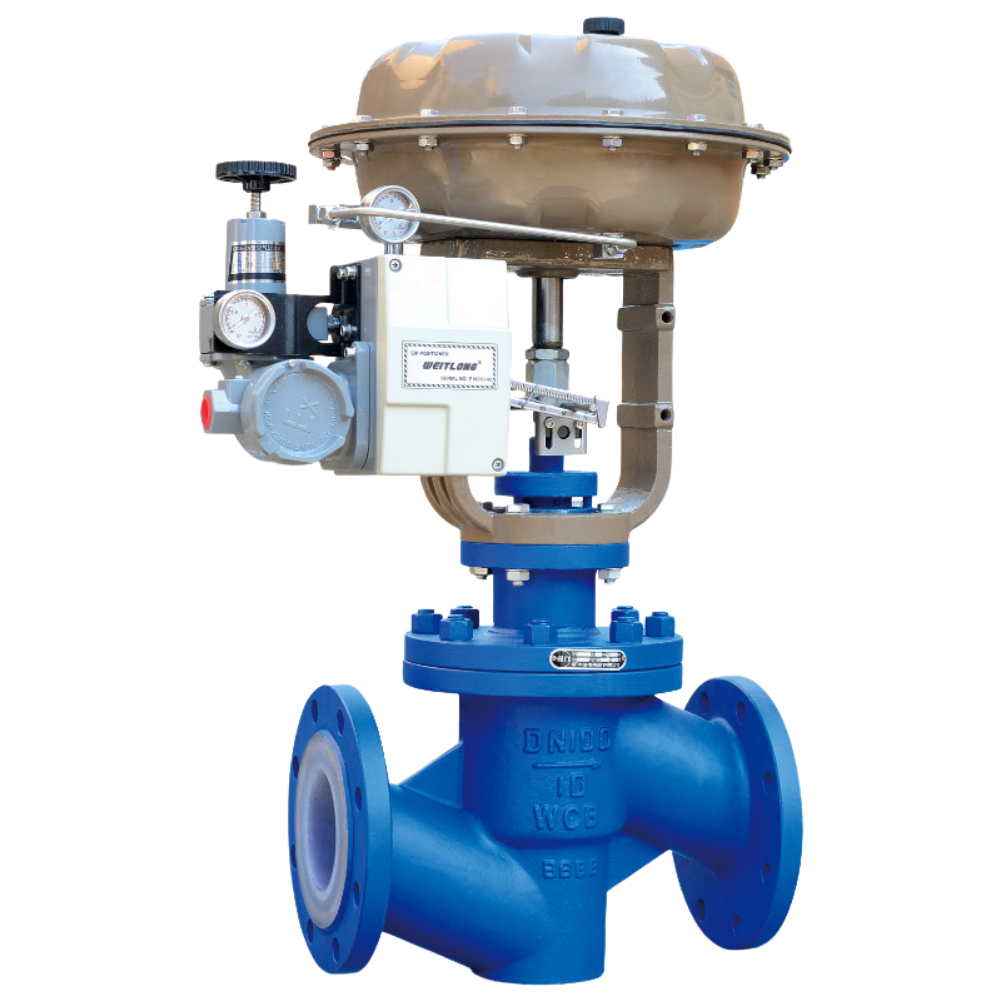

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]