A Fluorine lined wafer butterfly valve is a compact valve designed to clamp between two flanges in a pipeline, featuring four alignment holes. It provides a strong seal with a rubber or EPDM seat. Unlike lug-style valves, it cannot serve as an end-of-line valve and requires full line shutdown for maintenance.

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Disc | WCB | CF8 | CF3 | CF8M | CF3M |

| Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Lined | FEP / PFA / PO / PTFE | ||||

| Seat | PTFE / RPTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Design&Manufacture Standard | GB/T12238 | API 6D | ||

| FTF Dimension Standard | GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN40~DN1200 | 1-1/2”~48” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | Do | H |

| PN1.0MPa | ||||||||||

| 40 | 1-1/2 | 33 | 150 | 110 | 85 | 3 | 19 | 4-18 | 150 | 140 |

| 50 | 2 | 43 | 165 | 125 | 100 | 3 | 21 | 4-18 | 150 | 140 |

| 65 | 2-1/2 | 46 | 185 | 145 | 120 | 3 | 21 | 4-18 | 150 | 150 |

| 80 | 3 | 46 | 200 | 160 | 135 | 3 | 21 | 8-18 | 150 | 165 |

| 100 | 4 | 52 | 220 | 180 | 155 | 3 | 23 | 8-18 | 200 | 180 |

| 125 | 5 | 56 | 250 | 210 | 185 | 3 | 24 | 8-18 | 200 | 200 |

| 150 | 6 | 56 | 285 | 240 | 210 | 3 | 26 | 8-23 | 280 | 220 |

| 200 | 8 | 60 | 340 | 295 | 265 | 3 | 26 | 82-23 | 280 | 270 |

| 250 | 10 | 68 | 395 | 350 | 320 | 4 | 28 | 12-23 | 200 | 320 |

| 300 | 12 | 78 | 445 | 400 | 370 | 4 | 28 | 12-23 | 240 | 330 |

| 350 | 14 | 78 | 505 | 460 | 430 | 4 | 28 | 16-23 | 240 | 385 |

| 400 | 16 | 102 | 565 | 515 | 480 | 4 | 28 | 16-26 | 280 | 430 |

| 450 | 18 | 114 | 615 | 565 | 530 | 4 | 30 | 20-26 | 280 | 480 |

| 500 | 20 | 127 | 670 | 620 | 580 | 4 | 30 | 20-26 | 320 | 540 |

| 600 | 24 | 154 | 780 | 725 | 680 | 5 | 34 | 20-30 | 320 | 610 |

| 700 | 28 | 165 | 895 | 840 | 795 | 5 | 36 | 24-30 | 360 | 650 |

| 800 | 32 | 190 | 1015 | 950 | 900 | 5 | 38 | 24-33 | 360 | 710 |

| 900 | 36 | 203 | 1115 | 1050 | 1000 | 5 | 40 | 28-33 | 380 | 780 |

| 1000 | 40 | 216 | 1230 | 1160 | 1115 | 5 | 42 | 28-36 | 400 | 900 |

| 1200 | 48 | 254 | 1455 | 1380 | 1330 | 5 | 44 | 32-39 | 400 | 1050 |

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | Do | H |

| PN1.6MPa | ||||||||||

| 40 | 1-1/2 | 33 | 150 | 110 | 85 | 3 | 19 | 4-18 | 150 | 140 |

| 50 | 2 | 43 | 165 | 125 | 100 | 3 | 21 | 4-18 | 150 | 140 |

| 65 | 2-1/2 | 46 | 185 | 145 | 120 | 3 | 21 | 4-18 | 150 | 150 |

| 80 | 3 | 46 | 200 | 160 | 135 | 3 | 21 | 8-18 | 150 | 165 |

| 100 | 4 | 52 | 220 | 180 | 155 | 3 | 23 | 8-18 | 200 | 180 |

| 125 | 5 | 56 | 250 | 210 | 185 | 3 | 24 | 8-18 | 200 | 200 |

| 150 | 6 | 56 | 285 | 240 | 210 | 3 | 26 | 8-23 | 280 | 220 |

| 200 | 8 | 60 | 340 | 295 | 265 | 3 | 26 | 8-23 | 280 | 270 |

| 250 | 10 | 68 | 405 | 355 | 320 | 4 | 28 | 12-27 | 200 | 320 |

| 300 | 12 | 78 | 460 | 410 | 370 | 4 | 30 | 12-27 | 240 | 330 |

| 350 | 14 | 78 | 520 | 470 | 430 | 4 | 32 | 16-27 | 240 | 385 |

| 400 | 16 | 102 | 580 | 525 | 480 | 4 | 34 | 16-30 | 280 | 430 |

| 450 | 18 | 114 | 640 | 585 | 550 | 4 | 42 | 20-30 | 280 | 480 |

| 500 | 20 | 127 | 715 | 650 | 610 | 4 | 42 | 20-33 | 320 | 540 |

| 600 | 24 | 154 | 840 | 770 | 720 | 5 | 48 | 20-36 | 320 | 610 |

| 700 | 28 | 165 | 910 | 840 | 759 | 5 | 48 | 24-36 | 360 | 650 |

| 800 | 32 | 190 | 1025 | 950 | 900 | 5 | 48 | 24-39 | 360 | 710 |

| 900 | 36 | 203 | 1125 | 1050 | 1000 | 5 | 50 | 28-39 | 380 | 780 |

| 1000 | 40 | 216 | 1255 | 1170 | 1110 | 5 | 50 | 28-42 | 400 | 900 |

| 1200 | 48 | 254 | 1485 | 1390 | 1330 | 5 | 50 | 32-48 | 400 | 1050 |

The design and manufacture comply with the basic structure of Chinese national standards (the butterfly shaft coincides with the center of the valve body/seat)

A.D71F4 fully lined valve body, the whole village/butterfly plate, the whole village layer/lining layer, the butterfly plate and the butterfly plate shaft double D cooperate with

B.D71F46 fully lined valve body, full lining/plate, full lining/lining and butterfly plate into one

C.D71F4(46)/P semi-lined valve body is all solid/the butterfly plate is stainless steel/the butterfly plate is matched with the doubled of the butterfly plate shaft.

Their slim design saves space and makes them easy to install in systems with tight space constraints.

Wafer butterfly valves are economical due to their simple design and lower material requirements compared to other valve types.

They fit easily between flanges, without requiring additional bolts or fasteners, simplifying the installation process.

With fewer moving parts, they are easy to maintain and have a longer service life, reducing operational costs.

Wafer butterfly valves offer effective sealing, preventing backflow and ensuring system integrity across various applications.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

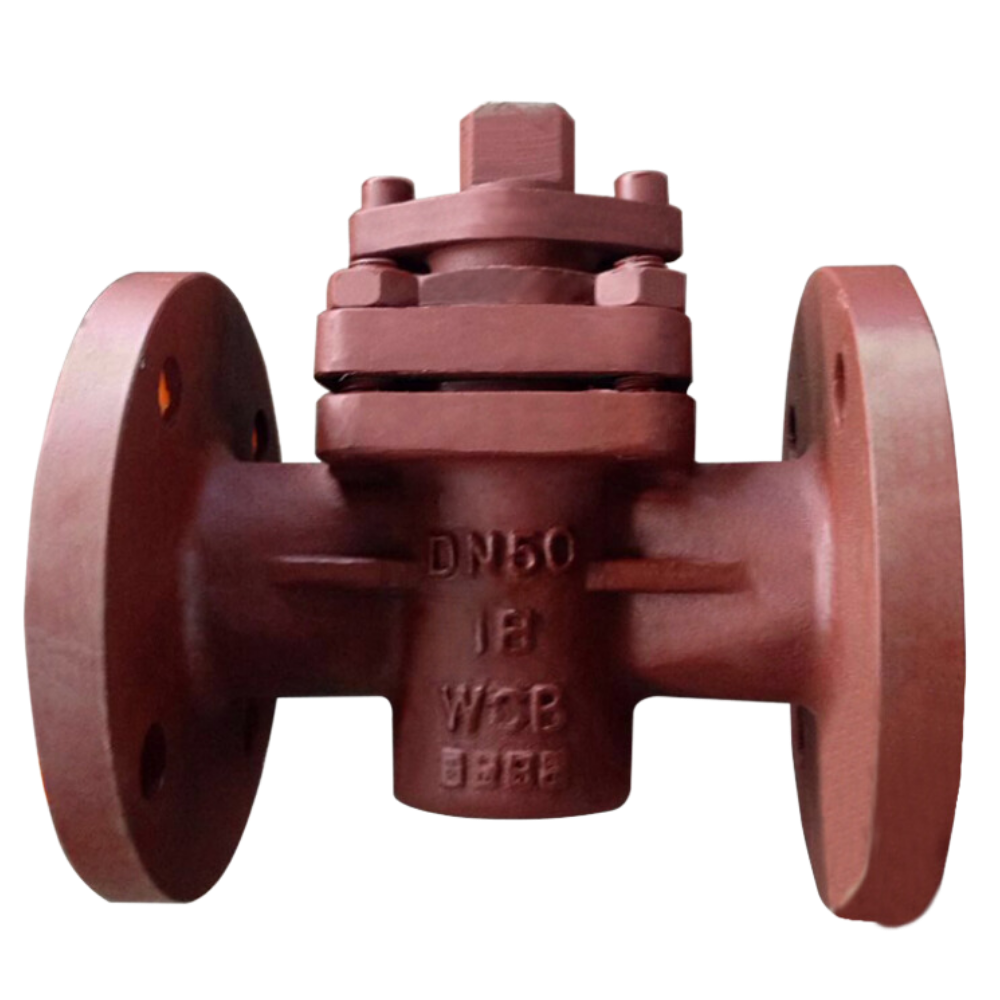

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

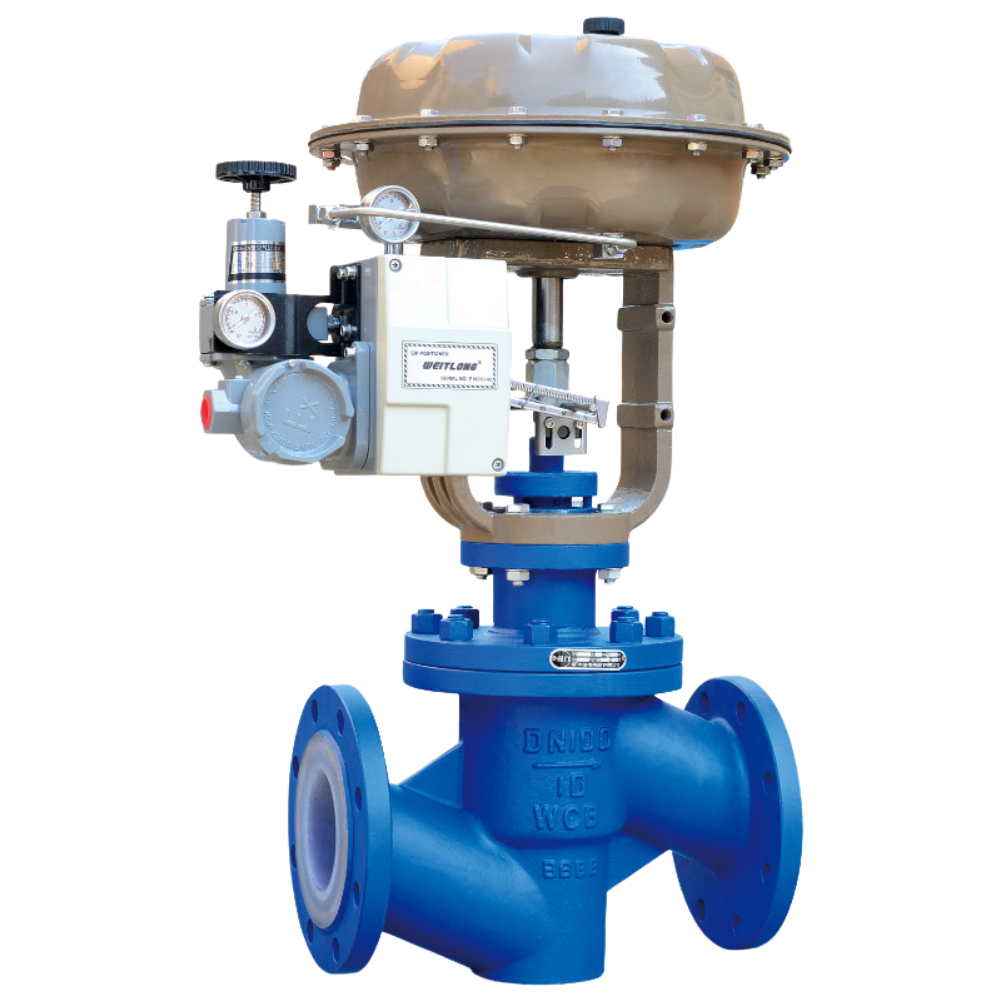

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]