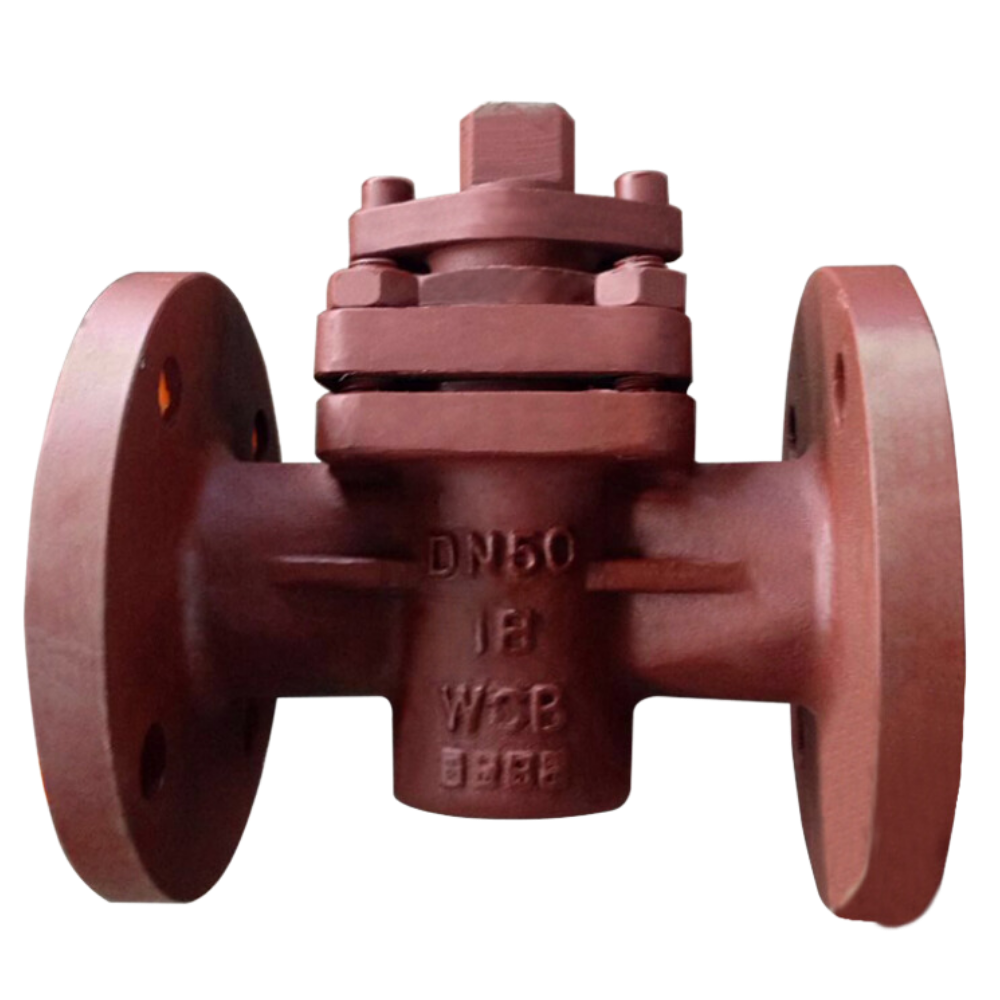

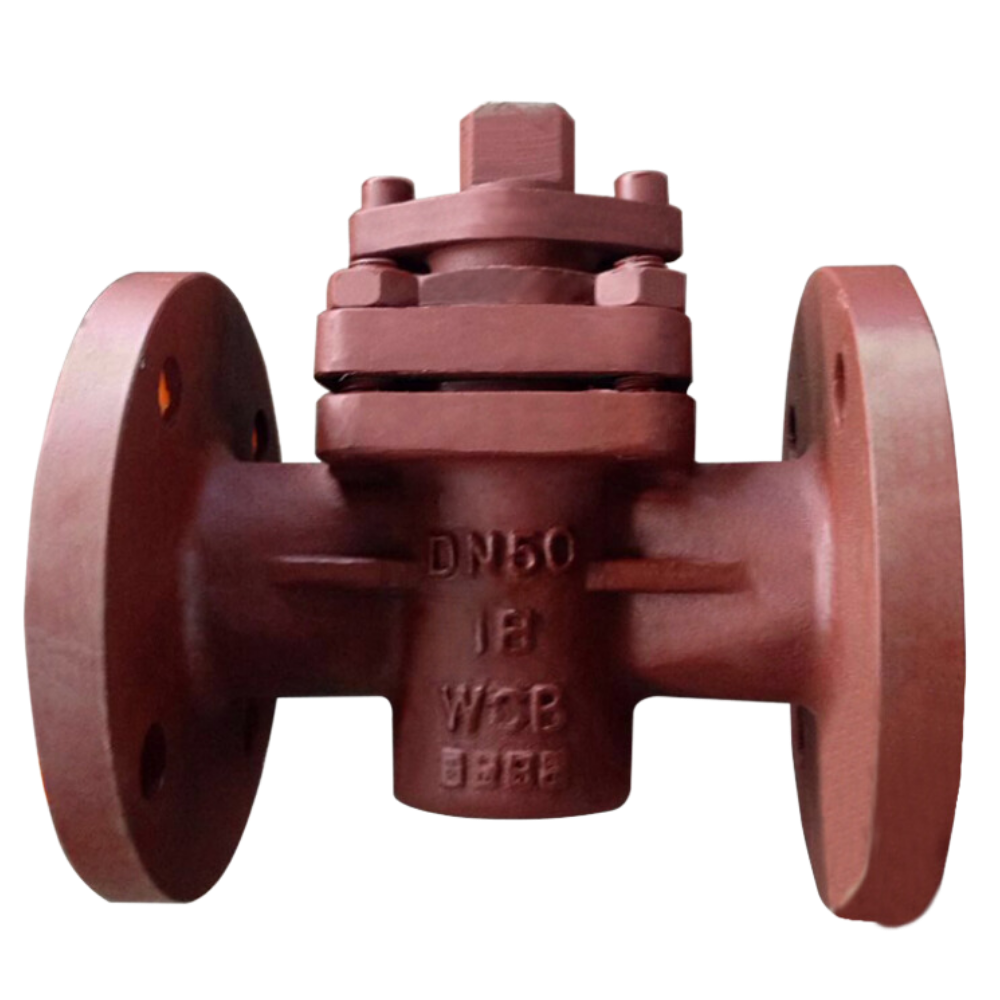

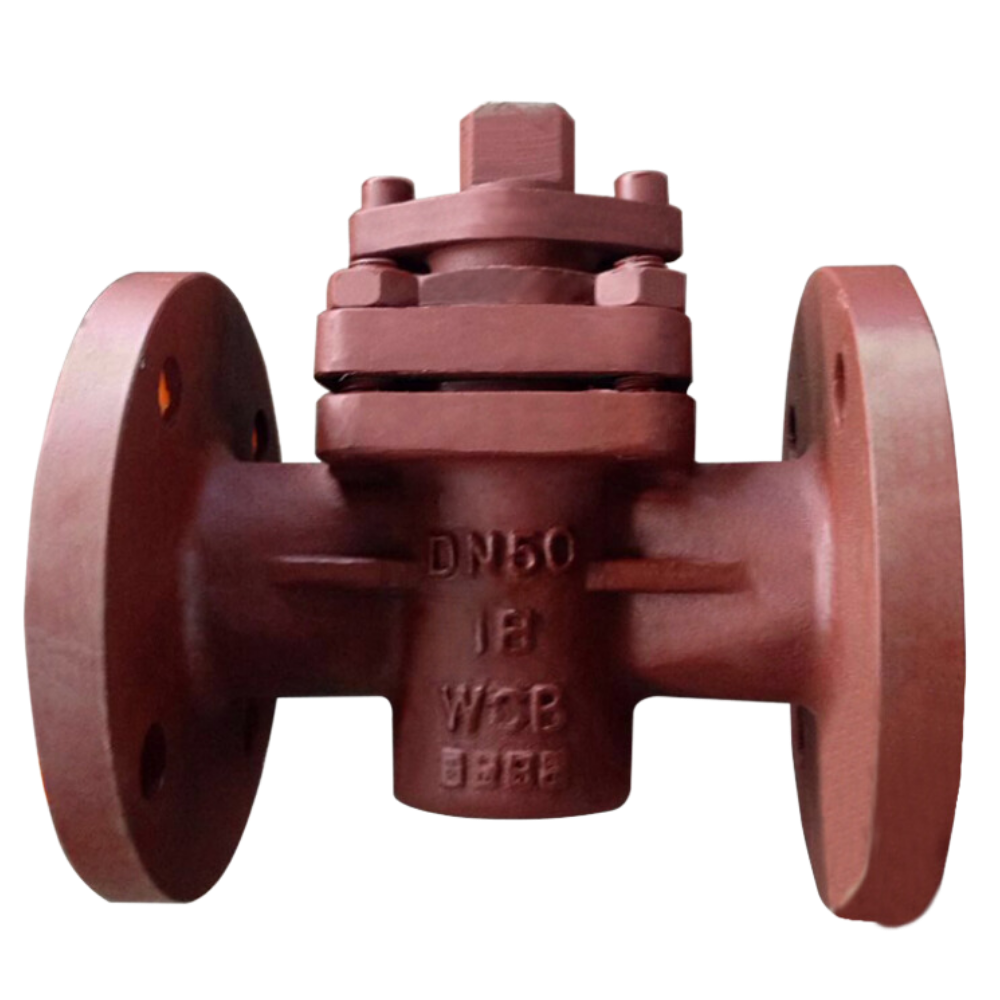

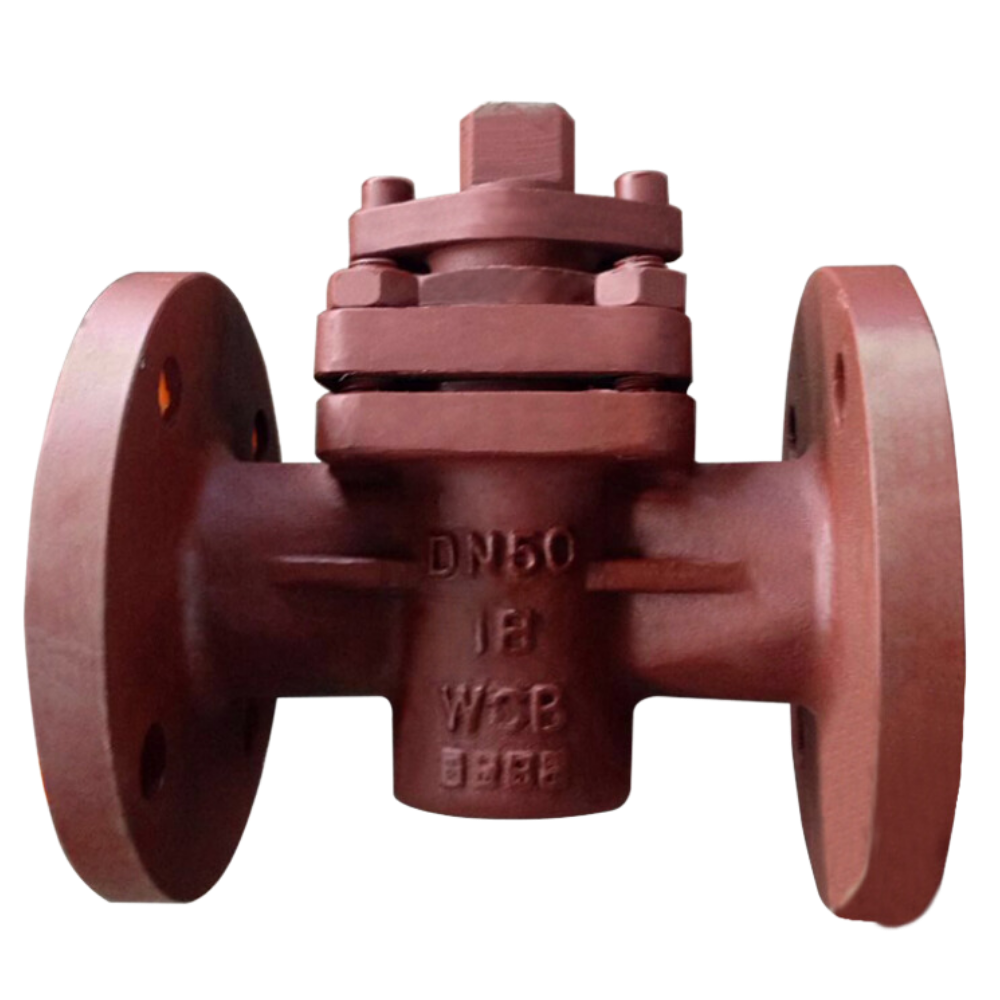

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path.

When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks the passage. Plug valves are valued for their straightforward design and reliability, making them suitable for applications requiring quick shut-off or isolation.

Main parts and materials

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Plug | WCB | CF8 | CF3 | CF8M | CF3M |

| Lined | FEP / PFA / PO / PTFE | ||||

| Seat | PTFE / RPTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

Technical Specification

| Design&Manufacture Standard | GB/T12240 | API 6D | ||

| FTF Dimension Standard | HG/T3704, GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN15~DN350 | 1/2”~14” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

The main connection size

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | H |

| 15 | 1/2 | 130 | 95 | 65 | 45 | 3 | 15 | 4-14 | 85 |

| 20 | 3/4 | 130 | 105 | 75 | 55 | 3 | 17 | 4-14 | 90 |

| 25 | 1 | 140 | 115 | 85 | 65 | 3 | 17 | 4-14 | 100 |

| 32 | 1-1/4 | 165 | 140 | 100 | 75 | 3 | 19 | 4-18 | 100 |

| 40 | 1-1/2 | 165 | 150 | 110 | 85 | 3 | 19 | 4-18 | 130 |

| 50 | 2 | 203 | 165 | 125 | 100 | 3 | 21 | 4-18 | 130 |

| 65 | 2-1/2 | 222 | 185 | 145 | 120 | 3 | 21 | 4-18 | 135 |

| 80 | 3 | 241 | 200 | 160 | 135 | 3 | 21 | 8-18 | 165 |

| 100 | 4 | 305 | 220 | 180 | 155 | 3 | 23 | 8-18 | 180 |

| 125 | 5 | 356 | 250 | 210 | 185 | 4 | 24 | 8-18 | 210 |

| 150 | 6 | 394 | 285 | 240 | 210 | 4 | 26 | 8-23 | 450 |

| 200 | 8 | 457 | 340 | 295 | 265 | 4 | 26 | 8/12-23 | 490 |

| 250 | 10 | 533 | 395 | 350 | 320 | 4 | 28 | 12-23/26 | 550 |

The fluorine-lined plug valve is a valve that uses a plug body with a through hole as the opening and closing member, and the plug body rotates with the stem to achieve the opening and closing action.The plug valve opens and closes quickly and the fluid resistance is small.

Plug valves feature a full port that aligns with the pipeline size. This design allows for high flow capacity and low flow restriction, making them suitable for applications where maintaining pressure is important. It also helps reduce turbulence and wear within the valve.

When closed, plug valves create a tight seal with the valve body, preventing leaks. This is vital in situations where leakage could pose safety risks or environmental issues. Their effective shut-off capability ensures complete isolation from the media.

Plug valves are built to withstand high pressures and temperatures due to their sturdy design and fewer moving parts. This simplicity reduces potential failure points, making them resistant to wear and corrosion, which is useful in tough industrial settings.

The design of plug valves allows for easy maintenance and repair. With fewer components than other valve types, they can be quickly disassembled for inspection or servicing. This simplicity can lead to less downtime and lower operational costs.

Plug valves can handle various fluids, including gases, liquids, and slurries. They are available in different materials to suit corrosive or abrasive substances, making them appropriate for many industries, such as oil and gas, chemical processing, and water treatment.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

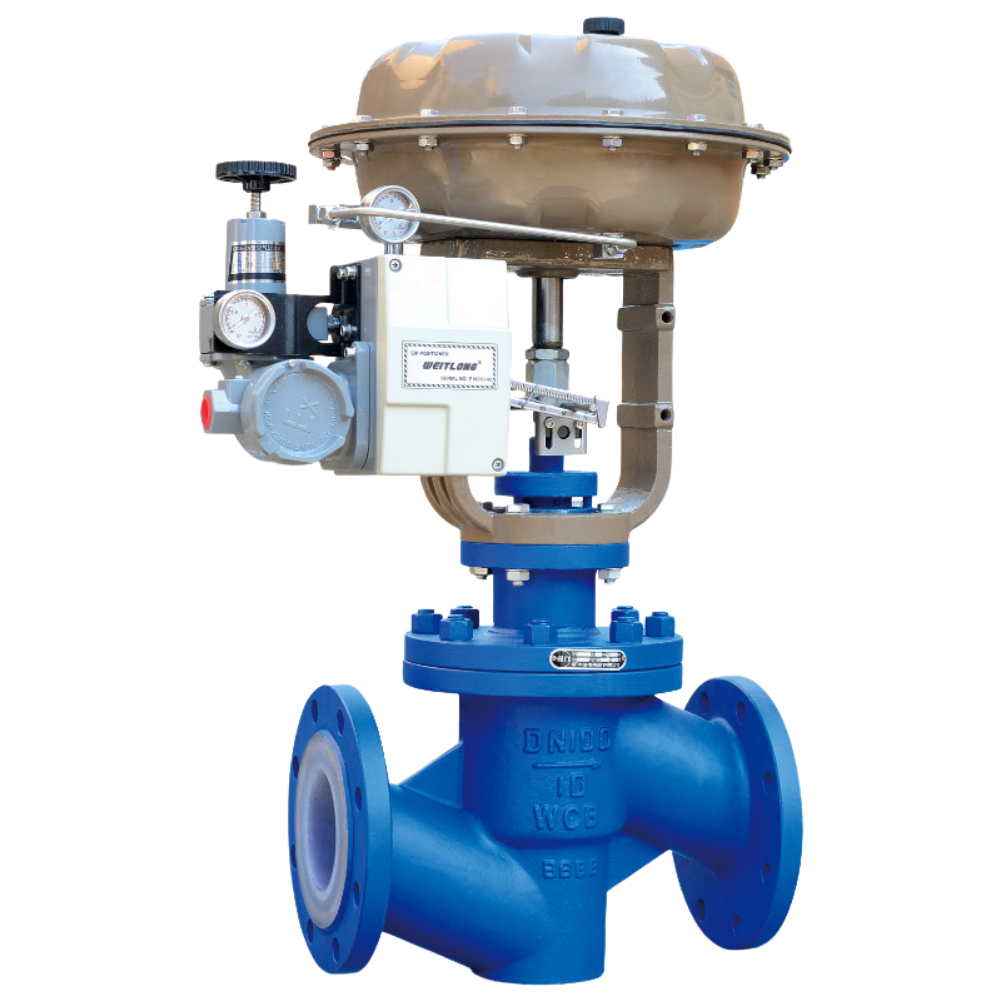

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]