The fluorine-lined butterfly valve is engineered for aggressive chemical and ultra-pure applications. Its fluorine lining resists chemical attack from various compounds, while a flexible 360-degree backup liner ensures bubble-tight shut-off. This maintenance-free valve features redundant shaft seals, a 90-degree clockwise operation, and zero leakage.

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Disc | WCB | CF8 | CF3 | CF8M | CF3M |

| Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Lined | FEP / PFA / PO / PTFE | ||||

| Seat | PTFE / RPTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Design&Manufacture Standard | GB/T12238 | API 6D | ||

| FTF Dimension Standard | GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN40~DN1200 | 1-1/2”~48” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | Do | H |

| PN1.0MPa | ||||||||||

| 40 | 1-1/2 | 106 | 150 | 110 | 85 | 3 | 19 | 4-18 | 150 | 140 |

| 50 | 2 | 108 | 165 | 125 | 100 | 3 | 21 | 4-18 | 150 | 140 |

| 65 | 2-1/2 | 112 | 185 | 145 | 120 | 3 | 21 | 4-18 | 150 | 150 |

| 80 | 3 | 114 | 200 | 160 | 135 | 3 | 21 | 8-18 | 150 | 165 |

| 100 | 4 | 127 | 220 | 180 | 155 | 3 | 23 | 8-18 | 200 | 180 |

| 125 | 5 | 140 | 250 | 210 | 185 | 3 | 24 | 8-18 | 200 | 200 |

| 150 | 6 | 140 | 285 | 240 | 210 | 3 | 26 | 8-23 | 280 | 220 |

| 200 | 8 | 152 | 340 | 295 | 265 | 3 | 26 | 8-23 | 280 | 270 |

| 250 | 10 | 165 | 395 | 350 | 320 | 4 | 28 | 12-23 | 200 | 320 |

| 300 | 12 | 178 | 445 | 400 | 370 | 4 | 28 | 12-23 | 240 | 330 |

| 350 | 14 | 190 | 505 | 460 | 430 | 4 | 28 | 16-23 | 240 | 385 |

| 400 | 16 | 216 | 565 | 515 | 480 | 4 | 28 | 16-26 | 280 | 430 |

| 450 | 18 | 222 | 615 | 565 | 530 | 4 | 30 | 20-26 | 280 | 480 |

| 500 | 20 | 229 | 670 | 620 | 580 | 4 | 30 | 20-26 | 320 | 540 |

| 600 | 24 | 267 | 780 | 725 | 680 | 5 | 34 | 20-30 | 320 | 610 |

| 700 | 28 | 292 | 895 | 840 | 795 | 5 | 36 | 24-30 | 360 | 650 |

| 800 | 32 | 318 | 1015 | 950 | 900 | 5 | 38 | 24-33 | 360 | 710 |

| 900 | 36 | 330 | 1115 | 1050 | 1000 | 5 | 40 | 28-33 | 380 | 780 |

| 1000 | 40 | 410 | 1230 | 1160 | 1115 | 5 | 42 | 28-36 | 400 | 900 |

| 1200 | 48 | 470 | 1455 | 1380 | 1330 | 5 | 44 | 32-39 | 400 | 1050 |

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | Do | H |

| PN1.6MPa | ||||||||||

| 40 | 1-1/2 | 106 | 150 | 110 | 85 | 3 | 19 | 4-18 | 150 | 140 |

| 50 | 2 | 108 | 165 | 125 | 100 | 3 | 21 | 4-18 | 150 | 140 |

| 65 | 2-1/2 | 112 | 185 | 145 | 120 | 3 | 21 | 4-18 | 150 | 150 |

| 80 | 3 | 114 | 200 | 160 | 135 | 3 | 21 | 8-18 | 150 | 165 |

| 100 | 4 | 127 | 220 | 180 | 155 | 3 | 23 | 8-18 | 200 | 180 |

| 125 | 5 | 140 | 250 | 210 | 185 | 3 | 24 | 8-18 | 200 | 200 |

| 150 | 6 | 140 | 285 | 240 | 210 | 3 | 26 | 8-23 | 280 | 220 |

| 200 | 8 | 152 | 340 | 295 | 265 | 3 | 26 | 8-23 | 280 | 270 |

| 250 | 10 | 165 | 405 | 355 | 320 | 4 | 28 | 12-27 | 200 | 320 |

| 300 | 12 | 178 | 460 | 410 | 370 | 4 | 30 | 12-27 | 240 | 330 |

| 350 | 14 | 190 | 520 | 470 | 430 | 4 | 32 | 16-27 | 240 | 385 |

| 400 | 16 | 216 | 580 | 525 | 480 | 4 | 34 | 16-30 | 280 | 430 |

| 450 | 18 | 222 | 640 | 585 | 550 | 4 | 42 | 20-30 | 280 | 480 |

| 500 | 20 | 229 | 715 | 650 | 610 | 4 | 42 | 20-33 | 320 | 540 |

| 600 | 24 | 267 | 840 | 770 | 720 | 5 | 48 | 20-36 | 320 | 610 |

| 700 | 28 | 292 | 910 | 840 | 759 | 5 | 48 | 24-36 | 360 | 650 |

| 800 | 32 | 318 | 1025 | 950 | 900 | 5 | 48 | 24-39 | 360 | 710 |

| 900 | 36 | 330 | 1125 | 1050 | 1000 | 5 | 50 | 28-39 | 380 | 780 |

| 1000 | 40 | 410 | 1255 | 1170 | 1110 | 5 | 50 | 28-42 | 400 | 900 |

| 1200 | 48 | 470 | 1485 | 1390 | 1330 | 5 | 50 | 32-48 | 400 | 1050 |

The fluorine-lined flange butterfly valve comprises a PTFE-lined valve body, disc, stem, seat, flanges, and seals. These components ensure corrosion resistance and reliable operation in harsh environments.

The fluorine-lined flange butterfly valve controls flow and isolates corrosive chemicals, offering excellent resistance to aggressive media, low torque operation, and reliable sealing in demanding environments.

A fluorine-lined flange butterfly valve operates by rotating a disc within the valve body to control the flow of fluids. The disc, lined with fluorine material like PTFE, pivots on a central axis. When the valve is fully open, the disc is parallel to the flow, allowing maximum passage. When closed, the disc is perpendicular to the flow, effectively sealing off the fluid.

Protect the PTFE flange cover during installation to avoid damage. Tighten flange nuts evenly and diagonally. Avoid high-temperature welding. Use gaskets when connecting with dissimilar materials. Store in a dry, ventilated space. After maintenance, test valves before reinstalling. Ensure proper medium flow direction, and avoid excessive force during manual operation.

Fluorine-lined flange butterfly valves are designed for harsh environments, utilizing components like a PTFE-lined valve body, disc, and seat to resist corrosion from aggressive chemicals.

These valves control the flow of corrosive fluids and provide reliable isolation by rotating a fluorine-lined disc within the valve body.

Valves in various materials like WCB, CF8, CF3, CF8M, and CF3M, with sizes ranging from DN40 to DN1200 (1-1/2” to 48”). They adhere to manufacturing standards such as GB/T12238, API 6D, and ASME B16.10

Proper installation requires protecting the PTFE flange cover, even tightening of flange nuts, and using gaskets with dissimilar materials. Regular maintenance and testing are crucial, ensuring the medium flows in the correct direction and avoiding excessive force during manual operation

Designed and manufactured in accordance with the basic structural form of the Chinese national standard (butterfly plate shaft aligns with valve body/valve seat center).

A. D41F4 fully lined type valve body with fully lined/butterfly plate fully lined; lining plate and butterfly plate shaft double-D matched.

B. D41F46 fully lined type.

C. D41F4(46)/P semi-lined type valve body with fully lined butterfly plate made of stainless steel; butterfly plate and butterfly plate shaft double-D matched.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

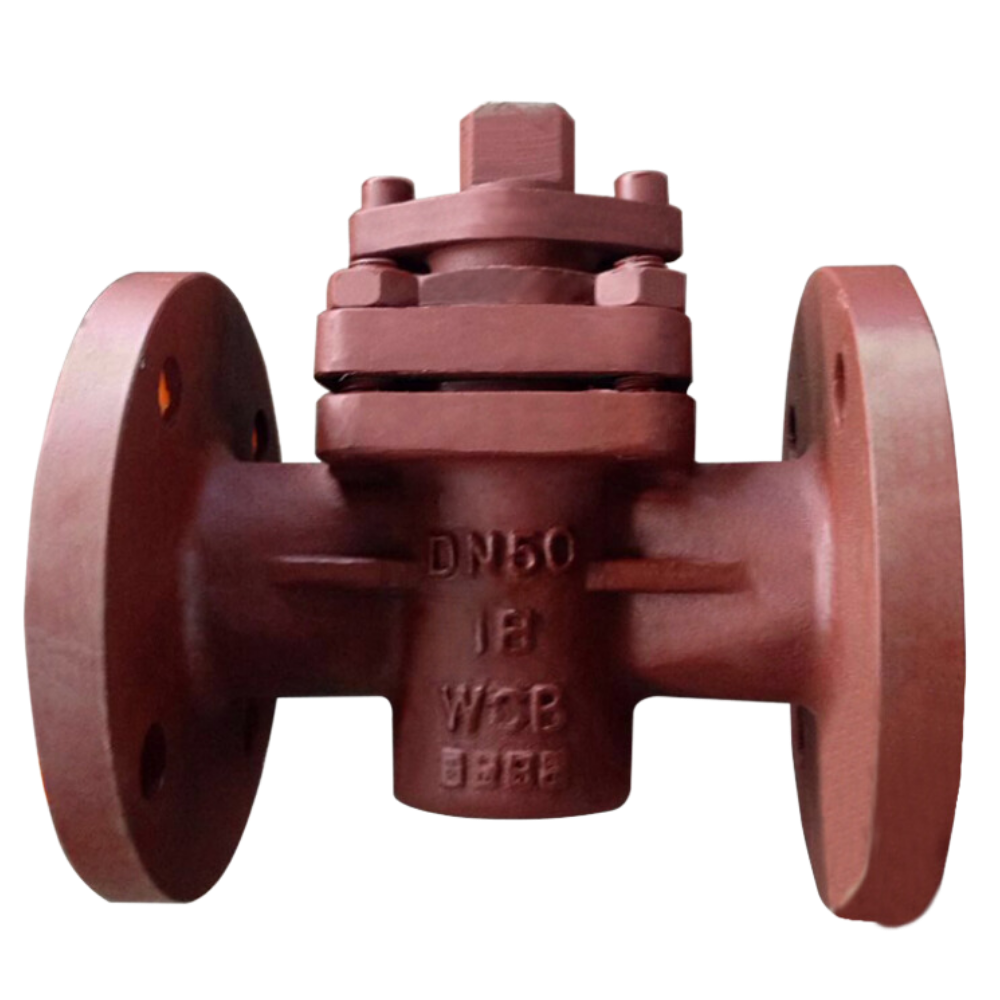

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

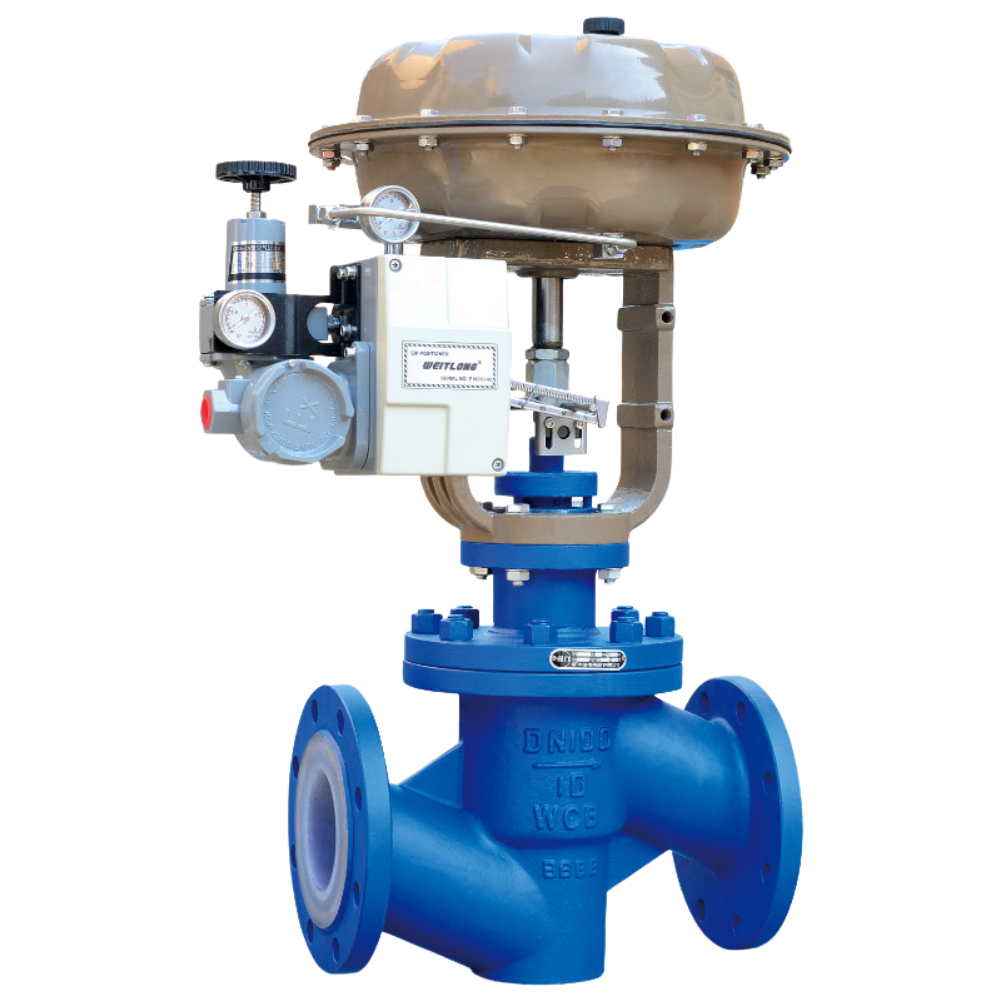

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]