The basket strainer is used for oil or other liquid pipelines to strainer the debris in the pipeline, and the strainer hole area is 2-3 times larger than the diameter pipe area. Far more than Y type, T type strainer area. The strainer structure is different from other strainer, because the shape is like a basket, so the name basket strainer.

The basket strainer is mainly composed of nozzle, barrel, strainer basket, flange, flange cover and fastener. Installed on the pipeline can remove large solid impurities in the fluid, so that the machine equipment (including compressors, pumps, etc.), instruments can work and operate normally, to stabilize the process and ensure the role of safe production.

Basket strainer is a small device to remove a small amount of solid particles in the liquid, which can protect the normal work of compressors, pumps, meters and other, when the fluid enters the filter bucket with a certain specification of the filter screen, its impurities are blocked, and the clean filtrate is discharged by the filter outlet, when it needs to be cleaned, as long as the detachable filter bucket is removed, and the process is re-loaded, so, Easy to use and maintain. It has been widely used in petroleum, chemical, pharmaceutical, food, environmental protection and other industries. If it is installed in series at the pump inlet or other parts of the system pipeline, it can extend the service life of the pump and other equipment, and ensure the safety of the entire syste.

Material Specification

| Nominal Diameter | Applicable to all specifications | |||

| Nominal Pressure | For each pressure | |||

| No. | Name | Material Lists | ||

| 1 | Drain | Q235/20# | 304 | 316L |

| 2 | Inlet Flange | Q235/20# | 304 | 316L |

| 3 | Branch pipe | Q235/20# | 304 | 316L |

| 4 | Major pipe | Q235/20# | 304 | 316L |

| 5 | Branch pipe | Q235/20# | 304 | 316L |

| 6 | Outlet Flange | Q235/20# | 304 | 316L |

| 7 | Skew Plate | Q235/20# | 304 | 316L |

| 8 | Strainer | 304 | 304 | 316L |

| 9 | Middle Flange | Q235/20# | 304 | 316L |

| 10 | Gasket | flexible graphite, Metal Spiral Wound Gasket | ||

| 11 | Middle flange cover | Q235/20# | 304 | 316L |

| 12 | Bolt nut | B7.2H | B8.8 | B8.8 |

| 13 | Vent | Q235/20# | 304 | 316L |

| 14 | handle | Q235/20# | 304 | 316L |

Note: the above materials are conventional materials. If you need special materials, please contact in advance.

Technical Specifications

| Design&Manufacture Standard | SH/T 3411-2017 |

| Face-to-face Dimension Standard | SH/T 3411-2017 |

| Flange Standard | GB/T 9119-2008JB/T 81-2015HG/T 20592-2009EN 1092-1ASME B16.5HG/T 20615-2009 |

| Nominal Diameter | Applicable to all specifications |

| Nominal Pressure | For each pressure |

| Test Pressure | 1.5 times design pressure |

| Filtering Accuracy | 5mesh~300mesh(4mm~0.05mm)5 mesh – 300 mesh (4mm~0.05mm) |

| Temperature Range | 0~300℃ |

| Applicable Medium | Water, steam, oil and other media |

Note: if non-standard customization is required, please explain in advance.

HG/T 20592-2009 PN16 Unit:mm

| SIZE | L | D | H | H1 | H2 | D1 | D2 | D3 | f | B | N-I | N3 | N4 |

| DN15 | 180 | 76 | 260 | 160 | 475 | 95 | 65 | 45 | 2 | 14 | 4-14 | 1/2” | |

| DN20 | 180 | 76 | 260 | 160 | 475 | 105 | 75 | 58 | 2 | 16 | 4-14 | 1/2” | |

| DN25 | 185 | 76 | 260 | 160 | 475 | 115 | 85 | 68 | 2 | 16 | 4-14 | 1/2” | |

| DN32 | 200 | 76 | 270 | 160 | 485 | 140 | 100 | 78 | 2 | 18 | 4-18 | 1/2” | |

| DN40 | 260 | 108 | 300 | 170 | 570 | 150 | 110 | 88 | 2 | 18 | 4-18 | 1/2” | 1/2” |

| DN50 | 260 | 108 | 300 | 170 | 570 | 165 | 125 | 102 | 2 | 19 | 4-18 | 1/2” | 1/2” |

| DN65 | 330 | 133 | 360 | 240 | 670 | 185 | 145 | 122 | 2 | 20 | 8-18 | 1/2” | 1/2” |

| DN80 | 340 | 159 | 400 | 250 | 750 | 200 | 160 | 138 | 2 | 20 | 8-18 | 1/2” | 1/2” |

| DN100 | 400 | 219 | 470 | 300 | 900 | 220 | 180 | 158 | 2 | 22 | 8-18 | 3/4” | 3/4” |

| DN125 | 480 | 273 | 550 | 360 | 1070 | 250 | 210 | 188 | 2 | 22 | 8-18 | 3/4” | 3/4” |

| DN150 | 500 | 273 | 630 | 420 | 1220 | 285 | 240 | 212 | 2 | 24 | 8-22 | 3/4” | 3/4” |

| DN200 | 560 | 325 | 780 | 530 | 1500 | 340 | 295 | 268 | 2 | 26 | 12-22 | 3/4” | 3/4” |

| DN250 | 660 | 426 | 930 | 640 | 1740 | 405 | 335 | 320 | 2 | 29 | 12-26 | 3/4” | 3/4” |

| DN300 | 750 | 456(*) | 1200 | 840 | 2280(*) | 460 | 410 | 378 | 2 | 32 | 12-26 | 3/4” | 3/4” |

| DN350 | 810 | 530(*) | 1370 | 920 | 2650(*) | 520 | 470 | 428 | 2 | 35 | 16-26 | 3/4” | 3/4” |

| DN400 | 900 | 550(*) | 1500 | 950 | 2960(*) | 580 | 525 | 490 | 2 | 38 | 16-30 | 1” | 1” |

| DN450 | 1000 | 630(*) | 1700 | 1000 | 3340(*) | 640 | 585 | 550 | 2 | 42 | 20-30 | 1” | 1” |

| DN500 | 1080 | 720(*) | 1910 | 1050 | 3760(*) | 715 | 650 | 610 | 2 | 46 | 20-33 | 1” | 1” |

| DN600 | 1180 | 820(*) | 1800 | 1200 | 3840(*) | 840 | 770 | 725 | 2 | 52 | 20-33 | 1” | 1” |

| DN700 | 1300 | 920(*) | 2200 | 1500 | 4140(*) | 910 | 840 | 795 | 2 | 36 | 24-36 | 1” | 1” |

| DN800 | 1400 | 1020(*) | 2200 | 1500 | 4140(*) | 1025 | 950 | 900 | 2 | 38 | 24-39 | 1” | 1” |

| DN900 | 1500 | 1120(*) | 2350 | 1600 | 4640(*) | 1125 | 1050 | 1000 | 2 | 40 | 28-39 | 1” | 1” |

HG/T 20615-2009 150LB Unit:mm

| SIZE | L | D | H | H1 | H2 | D1 | D2 | D3 | f | B | N-I | N3 | N4 |

| DN15 | 180 | 76 | 260 | 160 | 475 | 90 | 60.3 | 34.9 | 2 | 11.6 | 4-16 | 1/2” | |

| DN20 | 180 | 76 | 260 | 160 | 475 | 100 | 69.9 | 42.9 | 2 | 13.2 | 4-16 | 1/2” | |

| DN25 | 185 | 76 | 260 | 160 | 475 | 110 | 79.4 | 50.8 | 2 | 14.7 | 4-16 | 1/2” | |

| DN32 | 200 | 76 | 270 | 160 | 485 | 115 | 88.9 | 63.5 | 2 | 16.3 | 4-16 | 1/2” | |

| DN40 | 260 | 108 | 300 | 170 | 570 | 125 | 98.4 | 73.0 | 2 | 17.9 | 4-16 | 1/2” | 1/2” |

| DN50 | 260 | 108 | 300 | 170 | 570 | 150 | 120.7 | 92.1 | 2 | 19.5 | 4-18 | 1/2” | 1/2” |

| DN65 | 330 | 133 | 360 | 240 | 670 | 180 | 139.7 | 104.8 | 2 | 22.7 | 4-18 | 1/2” | 1/2” |

| DN80 | 340 | 159 | 400 | 250 | 750 | 190 | 152.4 | 127.0 | 2 | 24.3 | 4-18 | 1/2” | 1/2” |

| DN100 | 400 | 219 | 470 | 300 | 900 | 230 | 190.5 | 157.2 | 2 | 24.3 | 8-18 | 3/4” | 3/4” |

| DN125 | 480 | 273 | 550 | 360 | 1070 | 255 | 215.9 | 185.7 | 2 | 24.3 | 8-22 | 3/4” | 3/4” |

| DN150 | 500 | 273 | 630 | 420 | 1220 | 280 | 241.3 | 215.9 | 2 | 25.9 | 8-22 | 3/4” | 3/4” |

| DN200 | 560 | 325 | 780 | 530 | 1500 | 345 | 298.5 | 269.9 | 2 | 29.0 | 8-22 | 3/4” | 3/4” |

| DN250 | 660 | 426 | 930 | 640 | 1740 | 405 | 362.0 | 323.8 | 2 | 30.6 | 12-26 | 3/4” | 3/4” |

| DN300 | 750 | 456(*) | 1200 | 840 | 2280(*) | 485 | 431.8 | 381.0 | 2 | 32.2 | 12-26 | 3/4” | 3/4” |

| DN350 | 810 | 530(*) | 1370 | 920 | 2650(*) | 535 | 476.3 | 412.8 | 2 | 35.4 | 12-30 | 3/4” | 3/4” |

| DN400 | 900 | 550(*) | 1500 | 950 | 2960(*) | 595 | 539.8 | 469.9 | 2 | 37.0 | 16-30 | 1” | 1” |

| DN450 | 1000 | 630(*) | 1700 | 1000 | 3340(*) | 635 | 577.9 | 533.4 | 2 | 40.1 | 16-33 | 1” | 1” |

| DN500 | 1080 | 720(*) | 1910 | 1050 | 3760(*) | 700 | 635.0 | 584.2 | 2 | 43.3 | 20-33 | 1” | 1” |

| DN600 | 1180 | 820(*) | 1800 | 1200 | 3840(*) | 815 | 749.3 | 692.2 | 2 | 48.1 | 20-36 | 1” | 1” |

| DN700 | 1300 | 920(*) | 2200 | 1500 | 4140(*) | 925 | 863.6 | 800 | 2 | 71.9 | 28-36 | 1” | 1” |

| DN800 | 1400 | 1020(*) | 2200 | 1500 | 4140(*) | 1060 | 977.9 | 914 | 2 | 81.4 | 28-42 | 1” | 1” |

| DN900 | 1500 | 1120(*) | 2350 | 1600 | 4640(*) | 1170 | 1085.8 | 1022 | 2 | 90.9 | 32-42 | 1” | 1” |

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

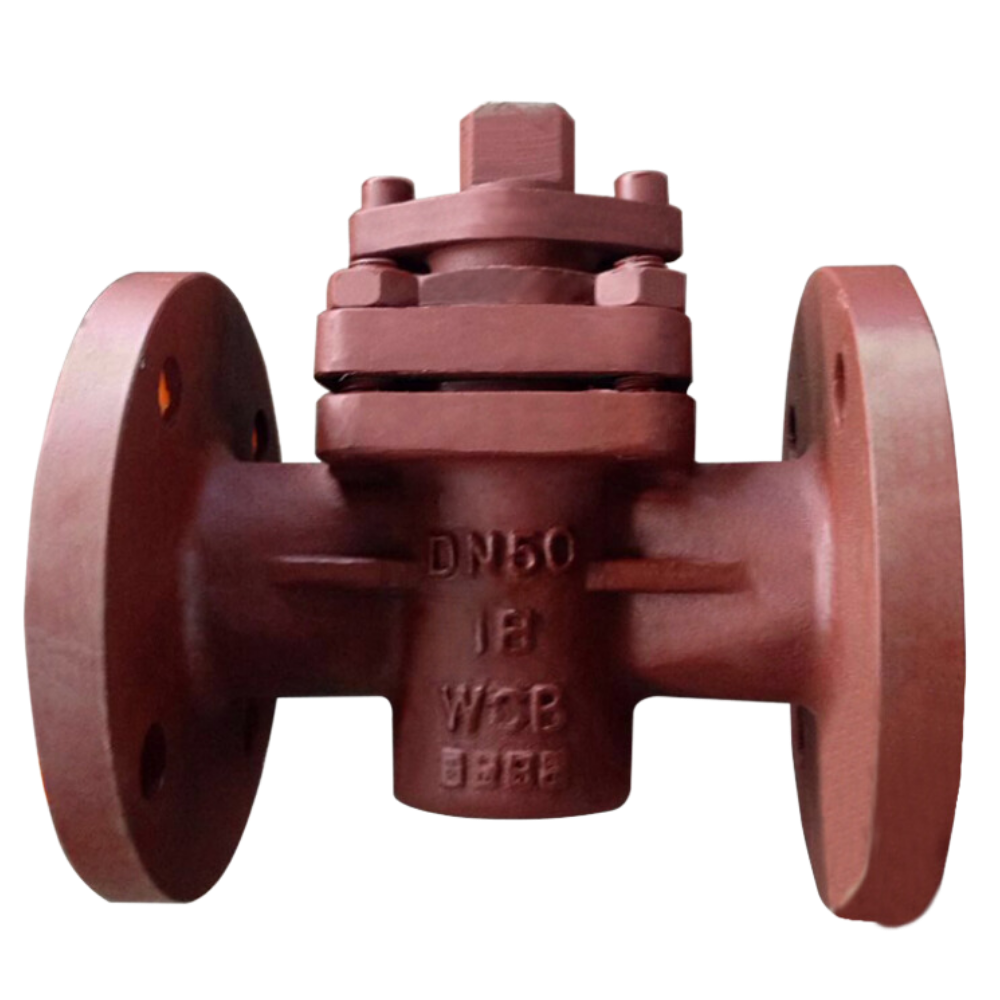

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

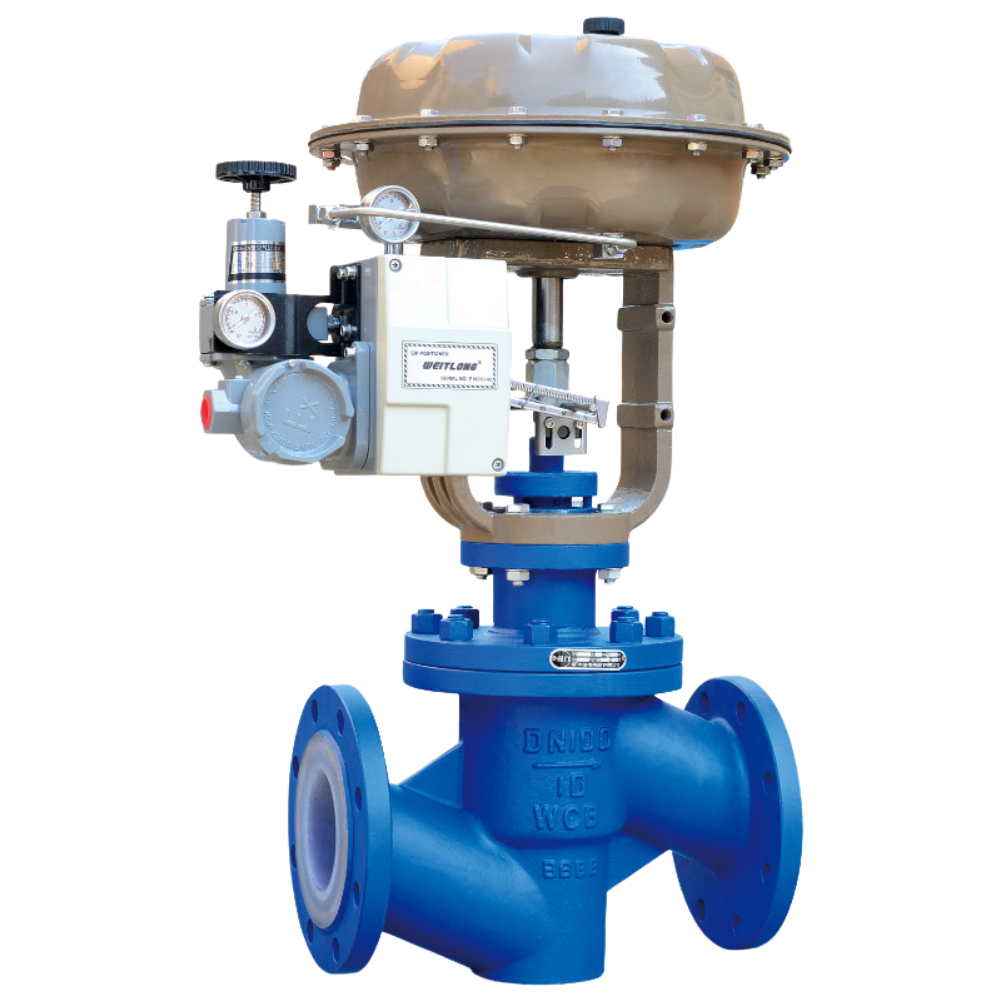

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]