Summarize

Bag filter is divided into top type (D type) and side type (C type) two types, there are single bag, multi-bag and double type (S type) a variety of model specifications, can be configured according to the medium requirements of different structures and materials of filter bags.

Top-in (D-type)

1: multi-set ring head bolt locking design.

2: The filter bag is subjected to 0.9Mpa water hammer pressure impact.

3: The top-in design makes the filtered liquid pass through the filter bag more evenly

Side-entry (type C)

1: side in side out or side in the bottom out of two, easy to disassemble and reduce costs.

2: Multi-bag type: 2~8 bag configuration, for large flow filtering options.

3: Dual structure is suitable for continuous filtration requirements.

4: Structure configuration selection: thermal insulation, heating jacket.

5: Open cover type: clamshell type, open translation type.

6: Bracket: looping lift type, mobile.

7: Truck-mounted pump with installation platform combination.

Typical application

1. Water treatment: system purification in the cooling unit, filtration of oil field water injection and no well fluid, purification of power plant condensate and ion exchange resin recovery.

2: Chemicals: catalyst recovery carbon removal ink and chemical aid.

3: Adhesive: in addition to acrylic binder, gel, hot melt polymer filter in addition to PVC clot.

4: lubricating oil, automobile manufacturing, aluminum manufacturing and other electronic industries.

Bag filter structure material

| Name | Bag filter |

| Model | JM-DS |

| Medium | Air,Liqiud |

| Body material | CS,SS |

| Filter material | PP,PTFE,PE |

| Conn. type | Clamp,flange |

| Flange | 0.25-6.3MPa, 150-300LB |

| Seal surface | RF, FM,TG |

| Gasket | PTFE,NBR,Metal graphite gasket |

| Flow rate | user-provided |

| Temp. | |

| Op. pressure | |

| Filter fineness | |

| Medium viscosity |

Parameter list

| Model Size | Filter size | Flow rate | |||||||||

| d | h | OD | H | H1 | H2 | L | E | DN | A | Qm³/h | |

| 180/400-1-f | 170 | 360 | 219 | 600 | 735 | 340 | 150 | 350 | 40 | 940 | 18 |

| 180/800-1-f | 170 | 360 | 219 | 1000 | 1135 | 340 | 150 | 350 | 50 | 1340 | 35 |

| 180/800-2-f | 170 | 360 | 400 | 1096 | 1215 | 410 | 325 | 560 | 100 | 1625 | 70 |

| 180/800-3-f | 170 | 760 | 450 | 1112 | 1215 | 440 | 215 | 650 | 125 | 1640 | 105 |

| 180/800-4-f | 170 | 760 | 500 | 1135 | 1230 | 460 | 239 | 740 | 150 | 1675 | 140 |

| 180/800-6-f | 170 | 760 | 500 | 1220 | 1275 | 505 | 505 | 900 | 200 | 1780 | 210 |

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

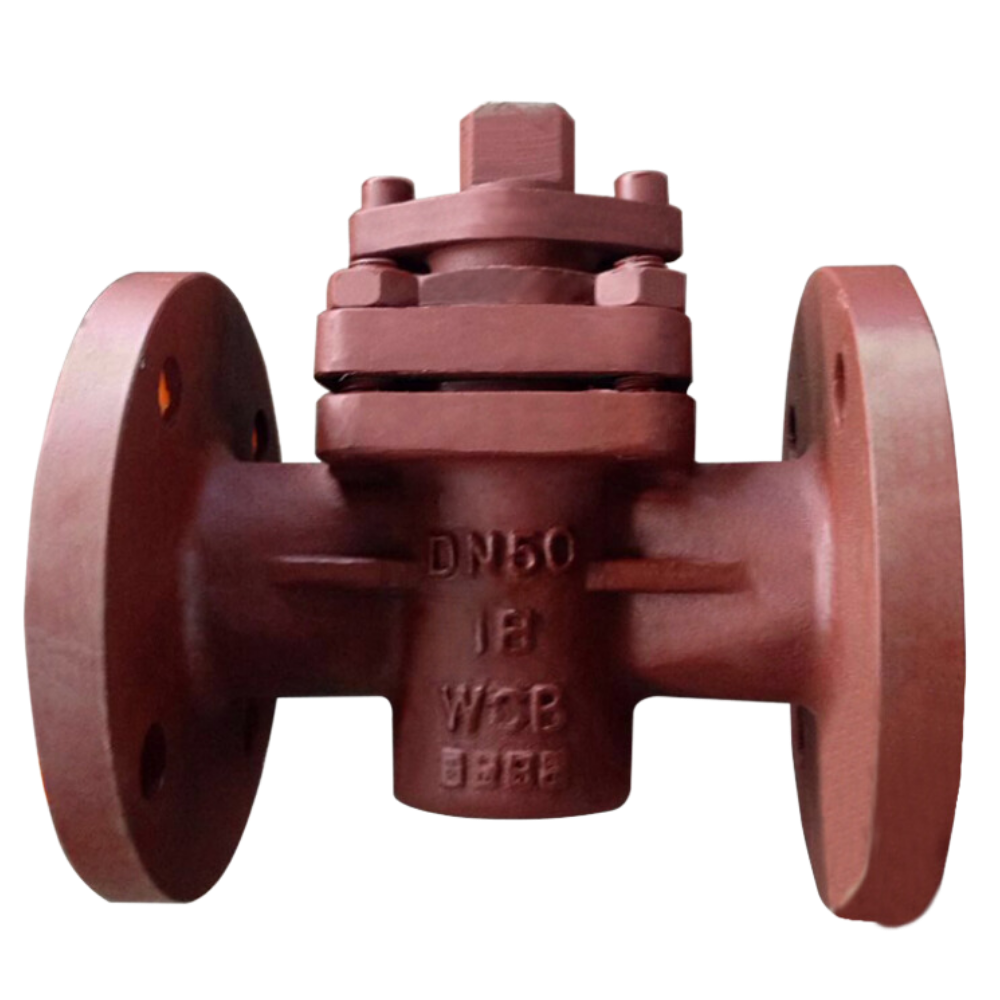

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

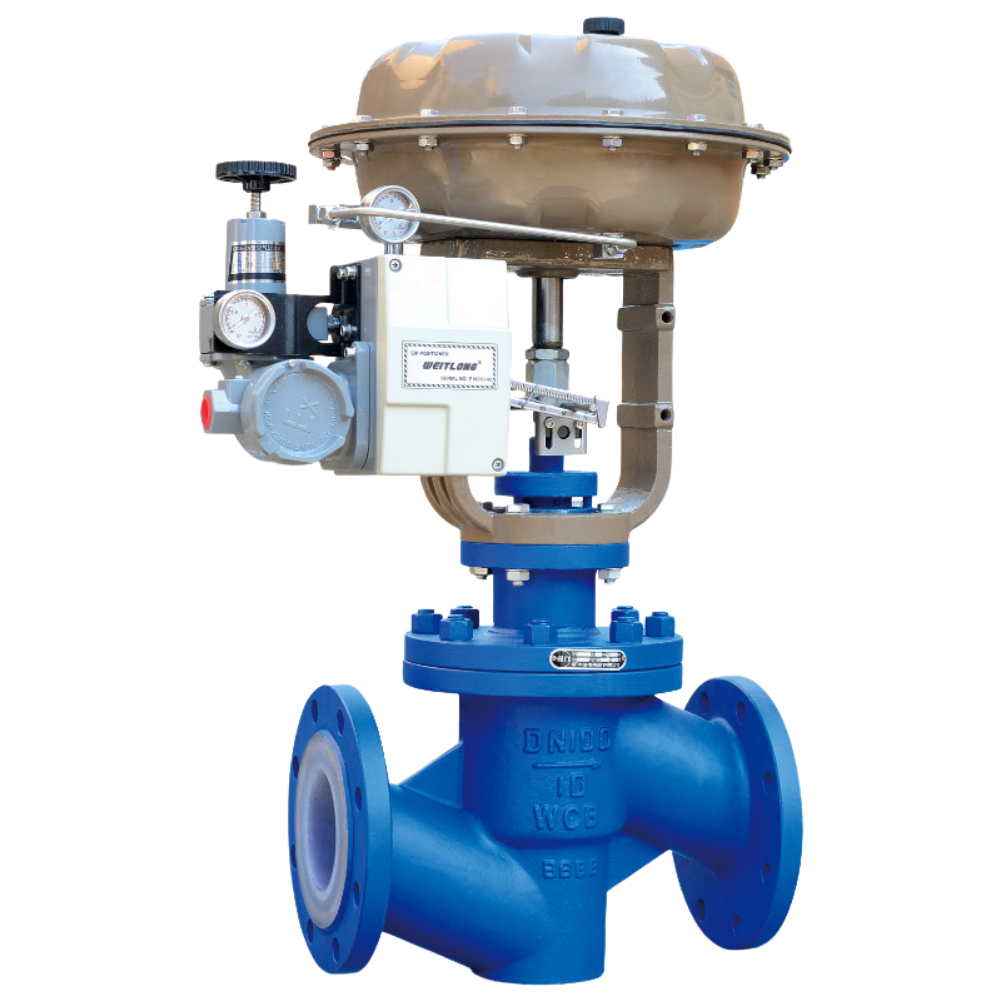

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]