Our pneumatic control pinch valve is designed for tough industrial applications, offering excellent control of abrasive and corrosive media, ensures reliable sealing, minimal maintenance, and long service life. Ideal for slurry, chemical, and wastewater systems. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the handle […]

Our heavy duty pneumatic pinch valve is designed for tough industrial applications, offering excellent control of abrasive and corrosive media, ensures reliable sealing, minimal maintenance, and long service life. Ideal for slurry, chemical, and wastewater systems, Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the […]

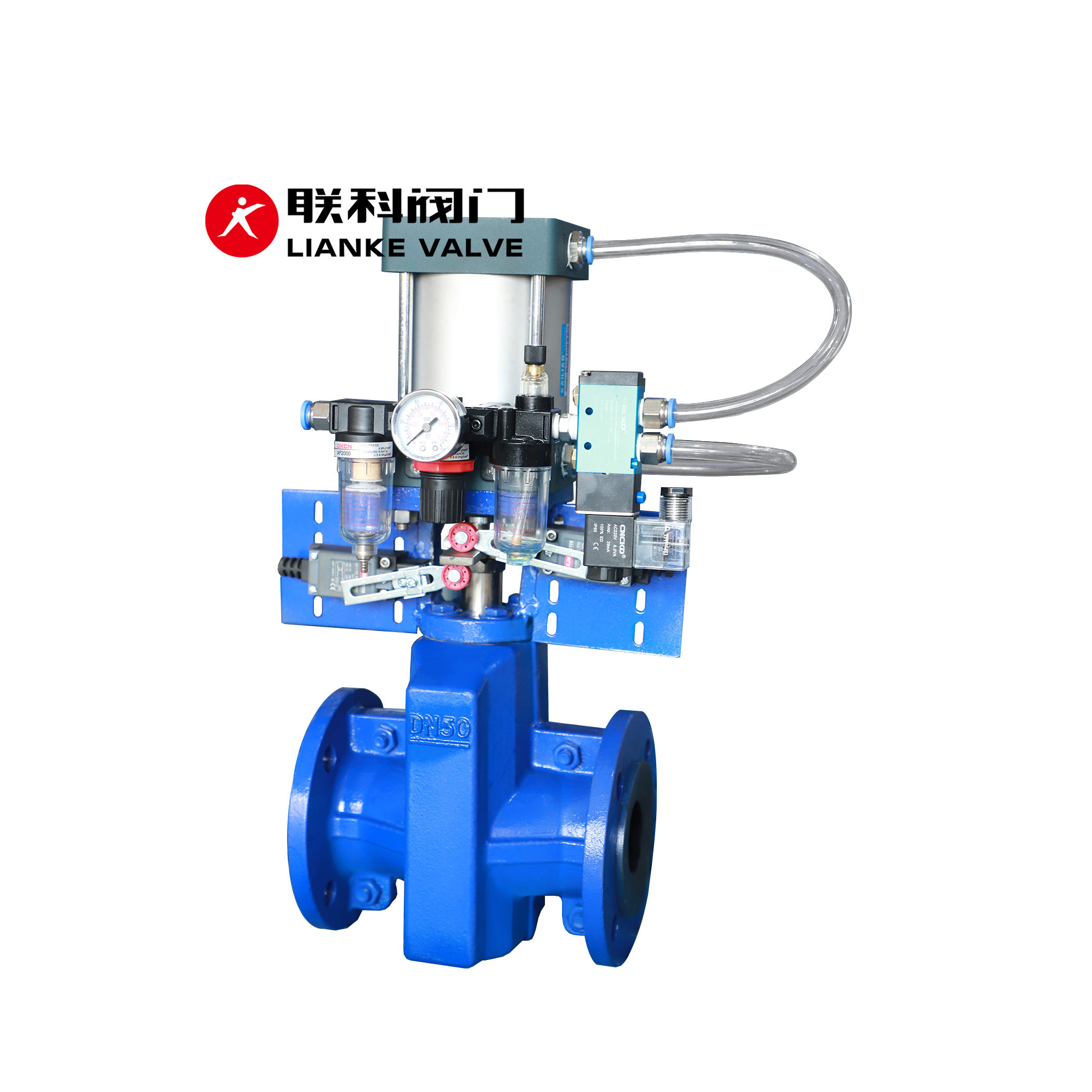

Solution for controlling the flow of corrosive, abrasive, and granular media in a variety of industrial applications. Designed to shut off or regulate flow with precision, utilizing pressurized air for effortless operation. Main property of the sleeve Rubber quality Application examples Temperature range Typical media EPDM Chemical applications: Applicable to 75% of all industrial chemical […]

Welding pneumatic pinch valves are 2/2-way valves that utilize pressurized air to open or close the valve, effectively managing the flow of corrosive, abrasive, or granular media, such as soldering agents. These valves are integral to creating the protective atmosphere required for submerged welding, ensuring that the welding process is efficient and effective Main of […]