Our pinch valve is ideal for media containing sediments, crystals, or abrasive materials. Common applications include wastewater treatment (sludge, grit, lime), power plants (FGD, ash removal), mining (tailings, slurries), chemical processes, and various industries. This pinch valve features unobstructed flow, full bore design, zero leakage even with particles present, and low maintenance. While temperature limited to -10~120°C due to rubber sealing, pinch valves suit most non-high-temperature applications. Operation is simple via pneumatic, electric, manual, or hydraulic actuation to compress the sleeve for flow control.

| Rubber quality | Application examples | Temperature range | Typical media |

| EPDM | Chemical applications: Applicable to 75% of all industrial chemical applications. | -40℃ – +110℃ | Concentrated and oxidiziing chemicals. |

| NR | High wear applications. | -40℃ – +80℃ | Abrasive materials, diluted acids, alkali & chemicals. |

| NBR | Applications involving oils, fats and hydrocarbon. | -30℃ – +100℃ | Oil, fats, fuels hydrocarbon, lubricants. |

| CR | Special-purpse chemical application: Resilient to ozone and averse weather | -40℃ – +100℃ | Chemicals, acids, several solvents, aliphatic oils, fats, lubricants |

| IIR | Special-purpse chemical application: Impermeable to gas | -40℃ – +100℃ | Concentrated and acidic chemicals, vegetable oil. |

| Name | Material |

| Body | Aluminium alloy, Cast iron, Cast steel, Stainless steel |

| Sleeve | NR, EPDM, NBR, CR, IIR |

| Stem | Carbon steel, Stainless steel, Alloy steel |

| Pinch rod | Ductile iron |

| Side guide rod | Carbon steel, Stainless steel, |

| Hand wheel | Cast iron |

| Acceptable other special requirements of the material | |

| DN | PN(Bar) | L | L1 | L0 | D | D1 | Z-ɸ | D0 | H |

| 25 | 1-16 | 145 | 124 | 31 | 115 | 85 | 4-14 | 120 | 150 |

| 32 | 1-16 | 160 | 145 | 40 | 135 | 100 | 4-18 | 140 | 174 |

| 40 | 1-16 | 180 | 157 | 50 | 145 | 110 | 4-18 | 140 | 186 |

| 50 | 1-16 | 210 | 160 | 60 | 160 | 125 | 4-18 | 160 | 205 |

| 65 | 1-16 | 250 | 199 | 74 | 180 | 145 | 4-18 | 160 | 238 |

| 80 | 1-16 | 300 | 222 | 88 | 195 | 160 | 4-18 | 200 | 241 |

| 100 | 1-16 | 350 | 250 | 106 | 215 | 180 | 8-18 | 240 | 301 |

| 125 | 1-10 | 430 | 318 | 134 | 245 | 210 | 8-18 | 280 | 360 |

| 150 | 1-10 | 500 | 350 | 158 | 280 | 240 | 8-23 | 320 | 405 |

| 200 | 1-6 | 645 | 446 | 206 | 335 | 295 | 8-23 | 560 | 545 |

| 250 | 1-6 | 800 | 516 | 256 | 395 | 350 | 12-23 | 560 | 632 |

| 300 | 1-4 | 940 | 562 | 304 | 440 | 400 | 12-23 | 620 | 741 |

| 350 | 1-4 | 840 | 500 | 460 | 16-23 | 700 | |||

| 400 | 1-4 | 915 | 580 | 525 | 16-25 | 750 |

Our Manual Pinch Valve is available with various sleeve materials, including EPDM for chemical applications, NR for high-wear scenarios, NBR for oils and fats, CR for ozone resistance, and IIR for impermeability to gases. The body can be constructed from aluminum alloy, cast iron, cast steel, or stainless steel, catering to diverse operational needs.

The Manual Pinch Valve operates by rotating the handwheel clockwise to engage the large and small valve stems, which compress the rubber tube sleeve between the upper and lower pressure plates, effectively closing the valve. Conversely, rotating the handwheel counterclockwise releases the pressure, allowing the valve to open. This straightforward mechanism ensures seamless on/off control and precise throttling capabilities.

Operators should be mindful of the rubber tube sleeve's limited bearing capacity. When opening or closing the valve, it is essential to feel the appropriate resistance when rotating the handwheel. Overexertion or using additional tools may damage the valve.

1.) With only the rubber sleeve requiring occasional replacement, this valve minimizes maintenance costs and downtime. Its straightforward design reduces the need for additional parts, making it a cost-effective solution, allowing easy operation with just a handwheel.

2.) Our Manual Pinch Valve can be installed in any part of the pipeline without restrictions on flow direction, making it adaptable to various systems, both economical and practical for long-term use

Whether you need an on/off service or throttling control, our pinch valve excels with its straight-through design that guarantees uninhibited flow and minimal pressure drop. The effective throttling ranges from 10% to 95% of the rated flow capacity means you get precise control in every situation.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

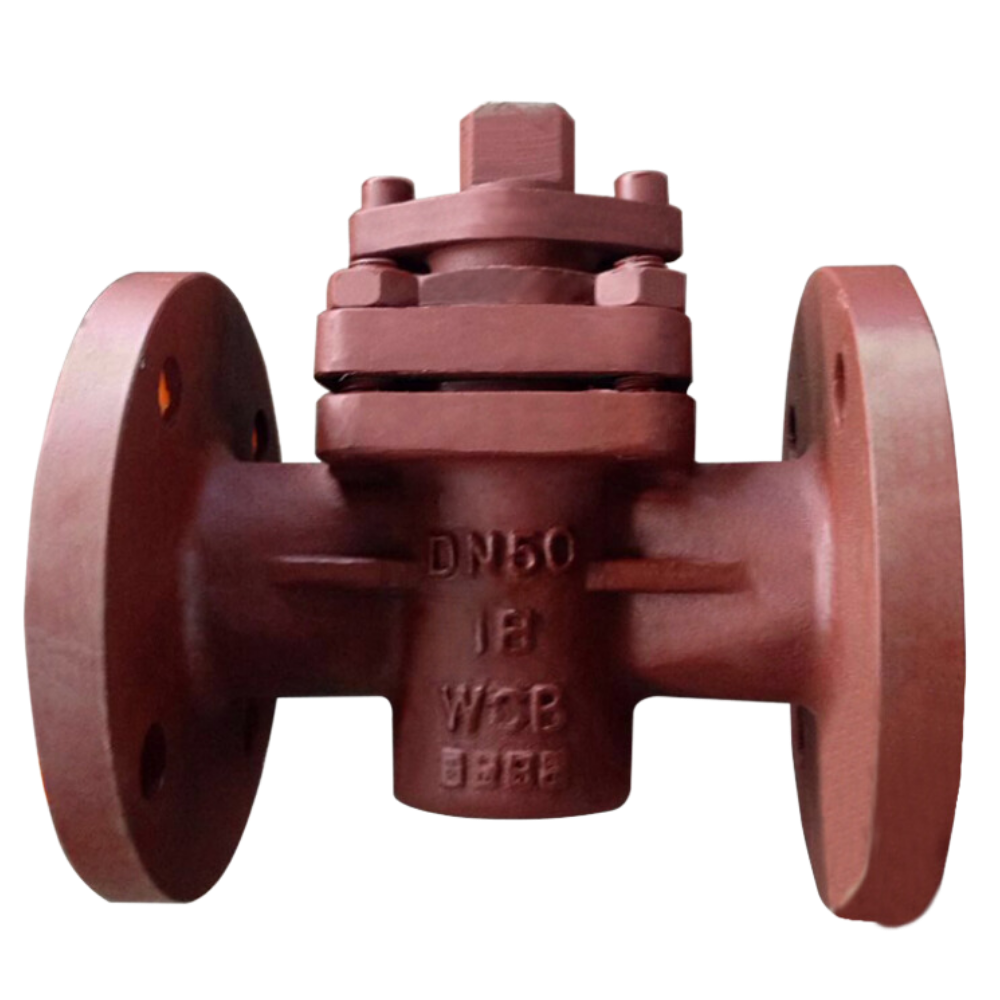

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

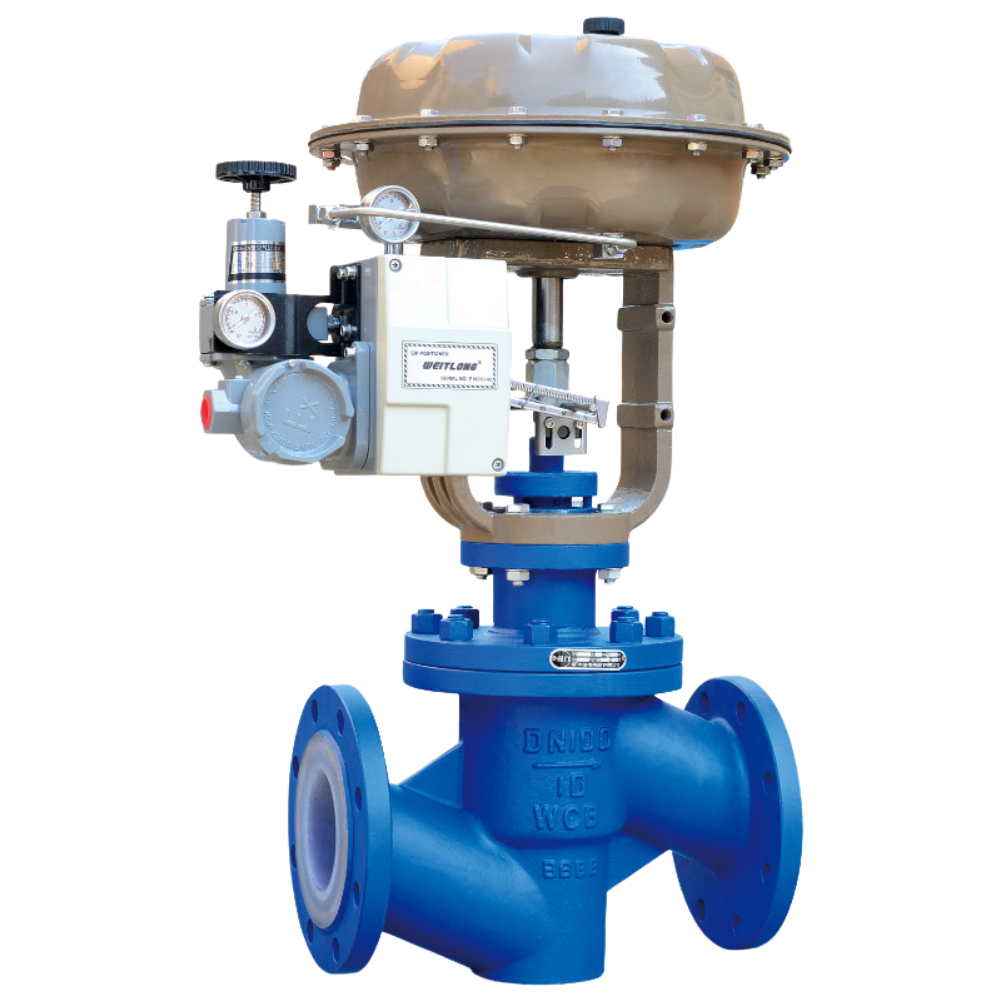

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]