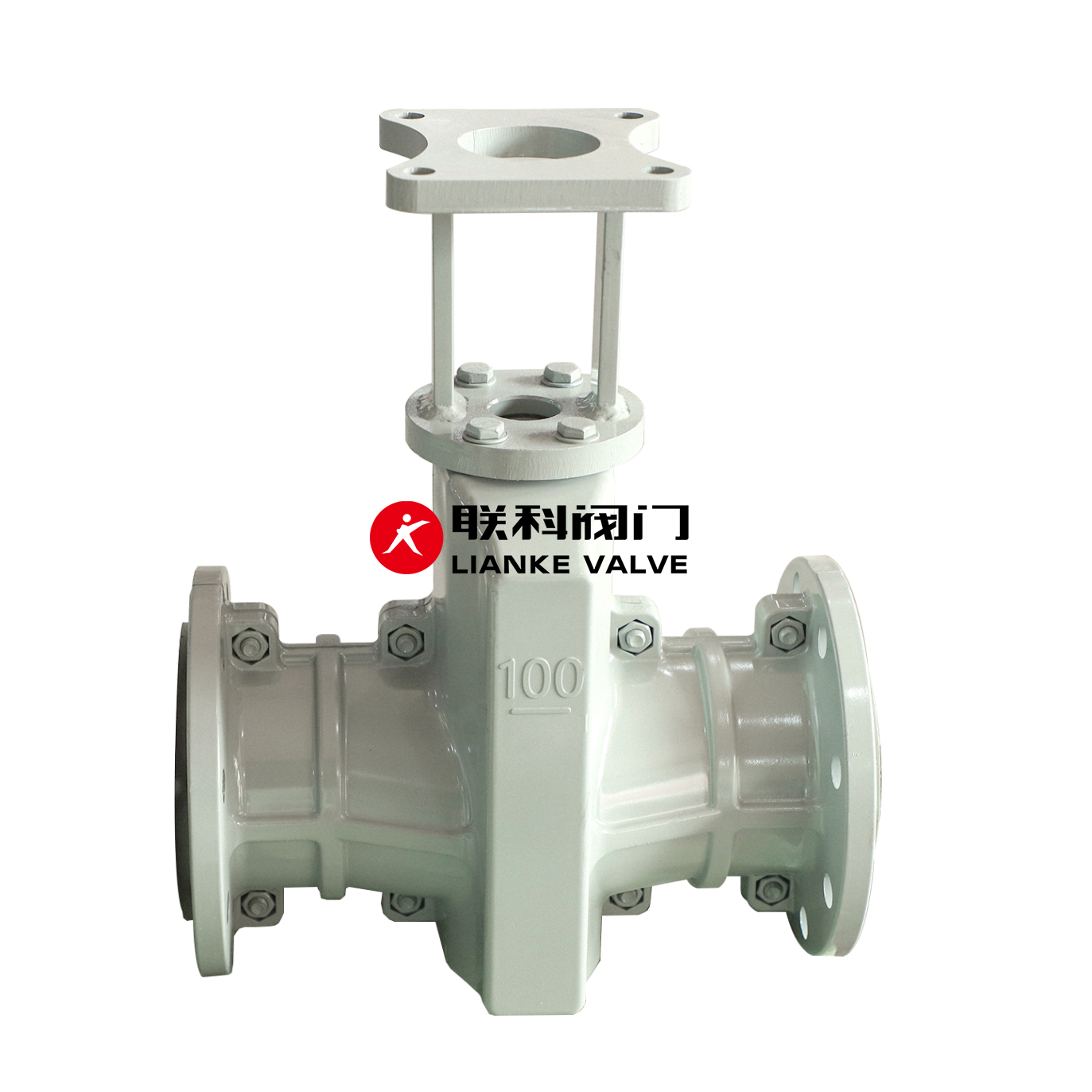

Our DN100 manual pinch valve offers efficient, low-maintenance flow control for abrasive and corrosive media. This pinch valve features a robust design, easy operation, and long-lasting rubber sleeve. Ideal for industrial pipelines, the DN100 pinch valve ensures reliable shut-off. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle […]

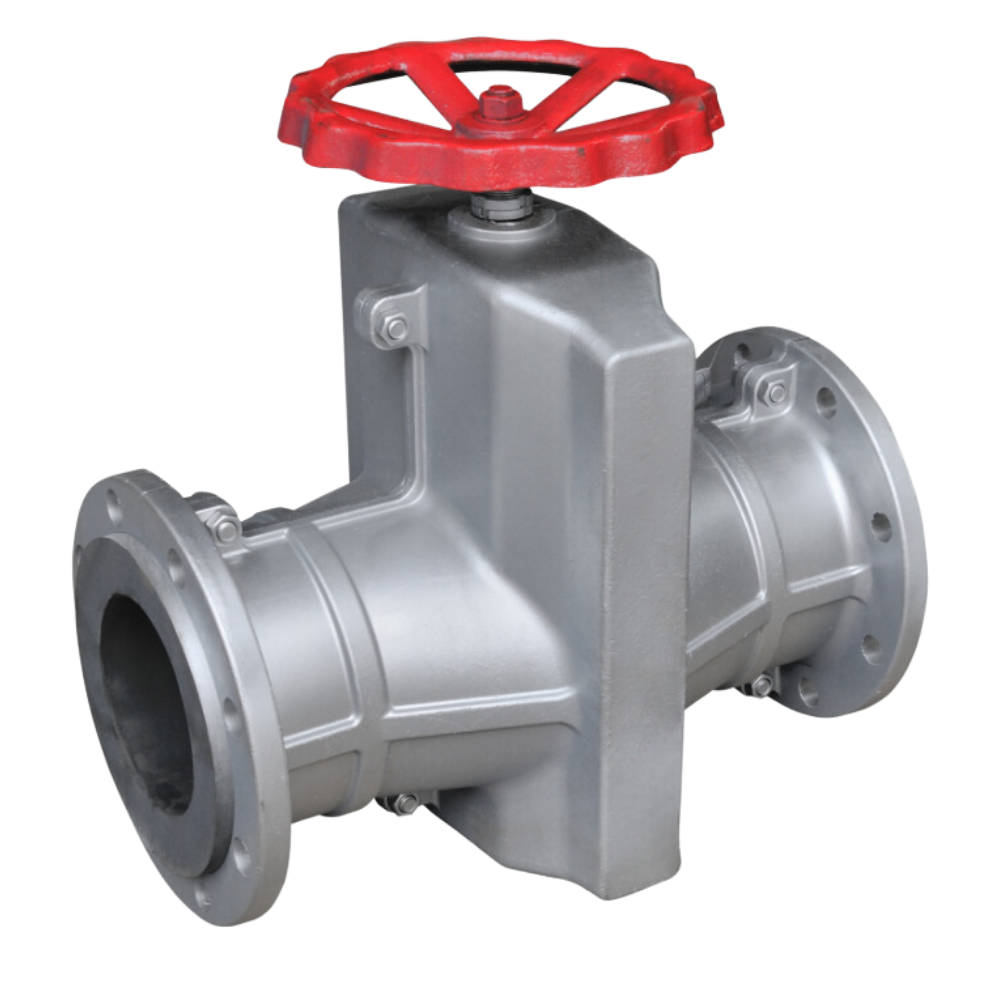

Our DN25 manual pinch valve is designed for tough industrial applications, offering excellent control of abrasive and corrosive media, ensures reliable sealing, minimal maintenance, and long service life. Ideal for slurry, chemical, and wastewater systems. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the handle […]

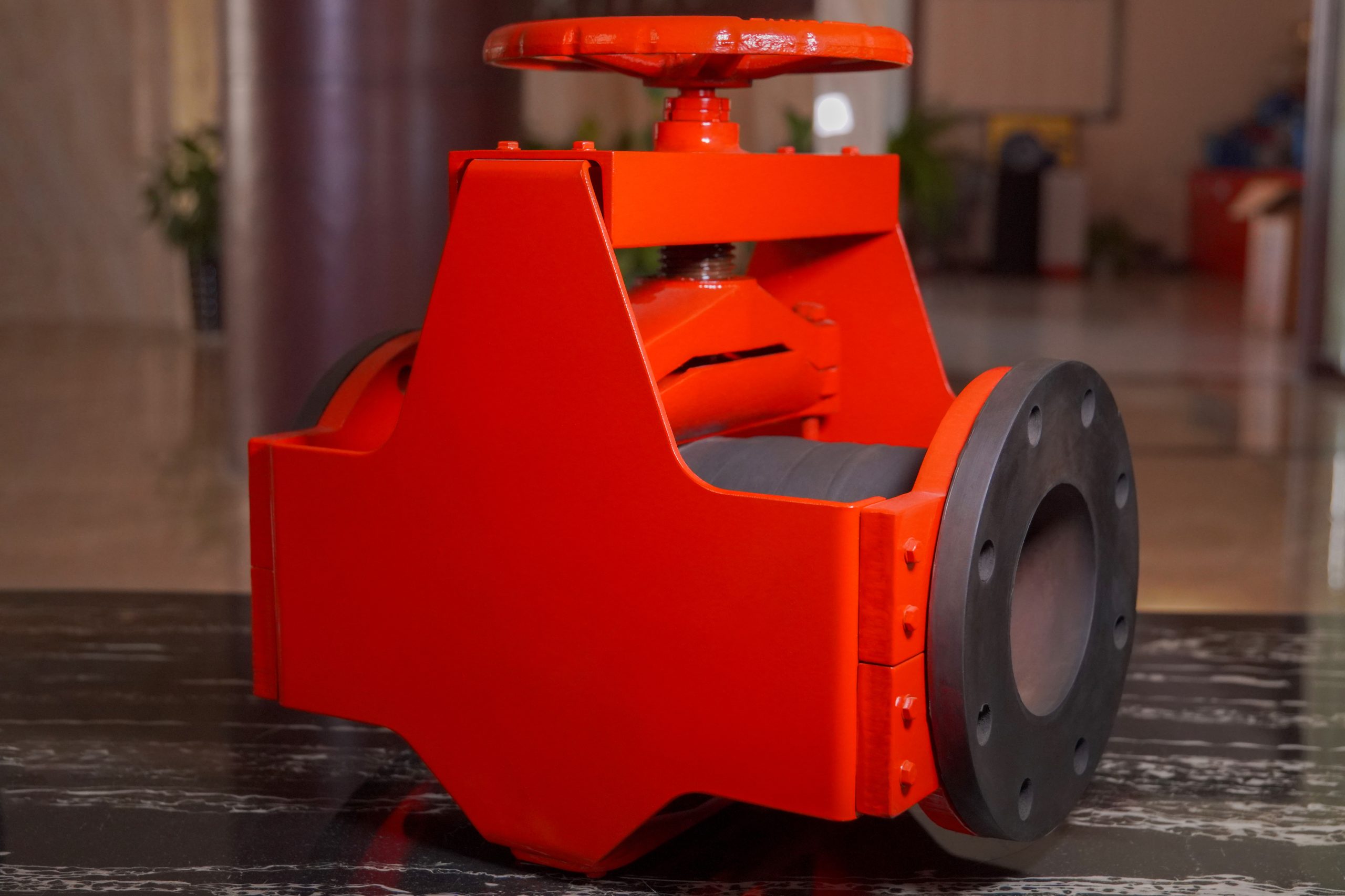

Our Open Body Manual Pinch Valve is designed for tough industrial applications, offering excellent control of abrasive and corrosive media, ensures reliable sealing, minimal maintenance, and long service life. Ideal for slurry, chemical, and wastewater systems. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the […]

Lianke Valves’ pinch valves deliver unmatched reliability in controlling abrasive, corrosive, and slurry media across industries. Engineered for durability and cost-efficiency, these pinch valves feature a robust design with a replaceable rubber sleeve that ensures zero-leakage shutoff and full-bore flow, eliminating clogging risks even with granular or viscous fluids. Main property of the sleeve Rubber […]

Our pinch valve is ideal for media containing sediments, crystals, or abrasive materials. Common applications include wastewater treatment (sludge, grit, lime), power plants (FGD, ash removal), mining (tailings, slurries), chemical processes, and various industries. This pinch valve features unobstructed flow, full bore design, zero leakage even with particles present, and low maintenance. While temperature limited […]