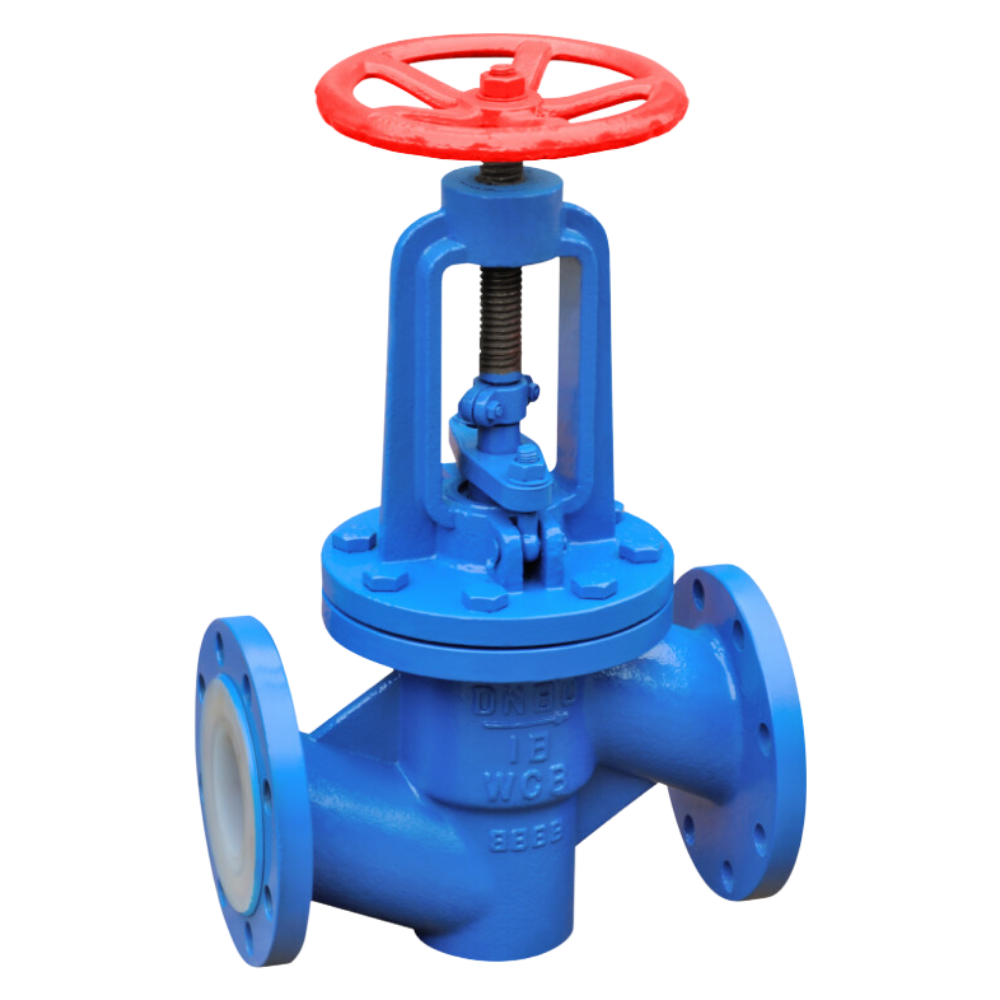

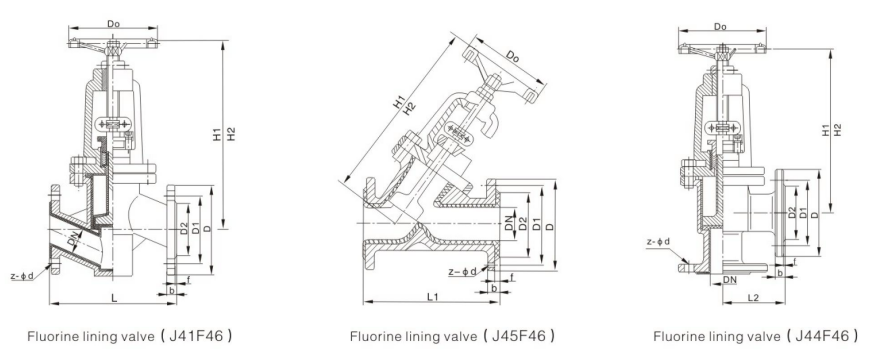

A fluorine-lined globe valve regulates the flow of corrosive fluids in industries such as chemical processing and water treatment. The internal surfaces are coated with fluorine to resist chemical corrosion.

The valve works by moving a plug or disc within a seat to control the flow of fluid. This design allows precise flow and pressure regulation. The fluorine lining protects the valve body from damage by corrosive substances.

Main parts and materials

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Plug | WCB | CF8 | CF3 | CF8M | CF3M |

| Lined | FEP / PFA / PO / PTFE | ||||

| Seat | PTFE / RPTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

Technical Specification

| Design&Manufacture Standard | GB/T12235 | API 6D | ||

| FTF Dimension Standard | HG/T3704, GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN15~DN350 | 1/2”~14” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

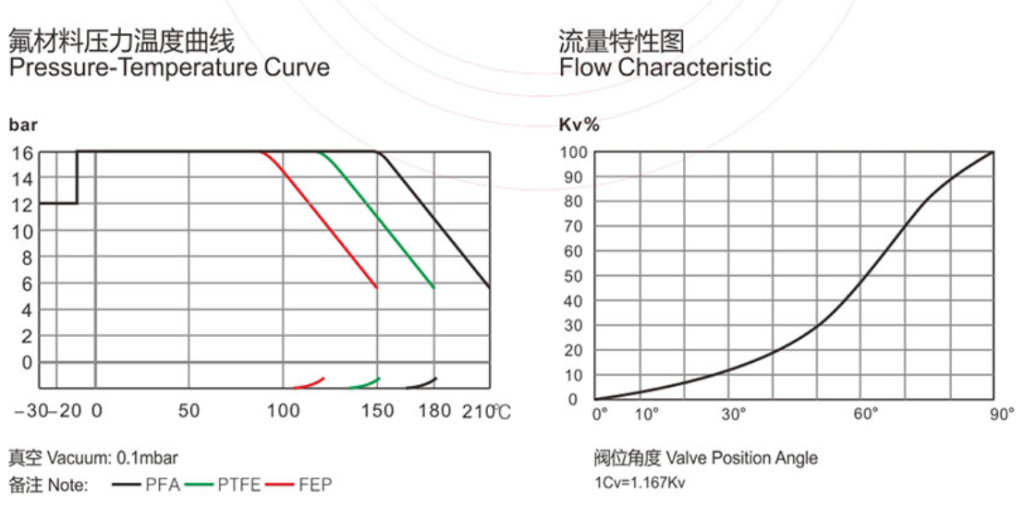

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

The main connection size

| DN (mm | PNS (Inch) | L | L1 | L2 | D | D1 | D2 | f | b | Z-Φd |

| PN10/16 | ||||||||||

| 25 | 1 | 160 | 160 | 100 | 115 | 85 | 65 | 3 | 17 | 4-14 |

| 32 | 1-1/4 | 180 | 180 | 105 | 140 | 100 | 75 | 3 | 19 | 4-18 |

| 40 | 1-1/2 | 200 | 200 | 115 | 150 | 110 | 85 | 3 | 19 | 4-18 |

| 50 | 2 | 230 | 230 | 125 | 165 | 125 | 100 | 3 | 21 | 4-18 |

| 65 | 2-1/2 | 290 | 290 | 145 | 185 | 145 | 120 | 3 | 21 | 4-18 |

| 80 | 3 | 310 | 310 | 155 | 200 | 160 | 135 | 3 | 21 | 8-18 |

| 100 | 4 | 350 | 350 | 175 | 220 | 180 | 155 | 3 | 23 | 8-18 |

| 125 | 5 | 400 | 400 | 200 | 250 | 210 | 185 | 4 | 24 | 8-18 |

| 150 | 6 | 480 | 480 | 225 | 285 | 240 | 210 | 4 | 26 | 8-23 |

| 200 | 8 | 600 | 600 | 275 | 340 | 295 | 265 | 4 | 26 | 8/12-23 |

| 250 | 10 | 730 | 730 | 325 | 395 | 350 | 320 | 4 | 28 | 12-23/26 |

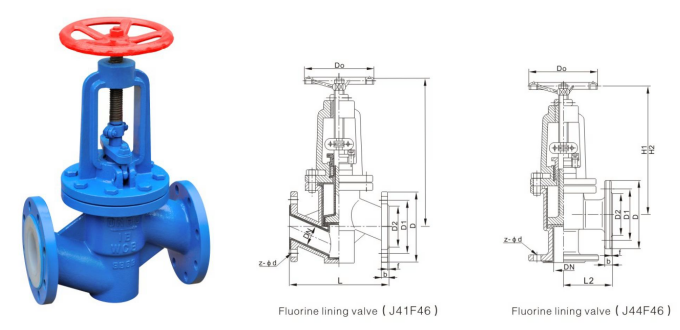

The opening and closing part of the fluorine-lined globe valve is a plug-shaped disc, the sealing surface is flat or conical, and the disc moves in a straight line along the center line of the fluid.The movement of the valve stem has a lifting rod type (the valve stem is raised and lowered, and the handwheel is not raised and lowered), as well as a lifting rotating rod type (the handwheel rotates and rises together with the valve stem, and the nut is arranged on the valve body).Globe valves are only suitable for fully open and fully closed, and adjustment and throttling are not allowed.

The fluorine lining provides strong protection against corrosive chemicals, ensuring the valve can handle aggressive fluids without degradation.

Globe valves are known for their ability to regulate flow accurately, and the fluorine lining enhances their durability in harsh environments.

The lining helps prevent wear and chemical attack, significantly extending the lifespan of the valve, even in demanding applications.

The fluorine lining creates a non-reactive barrier, preventing the valve from contaminating the fluid, which is crucial for sensitive processes.

Fluorine-lined globe valves can withstand a wide range of temperatures, maintaining reliable performance in both high and low-temperature applications.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

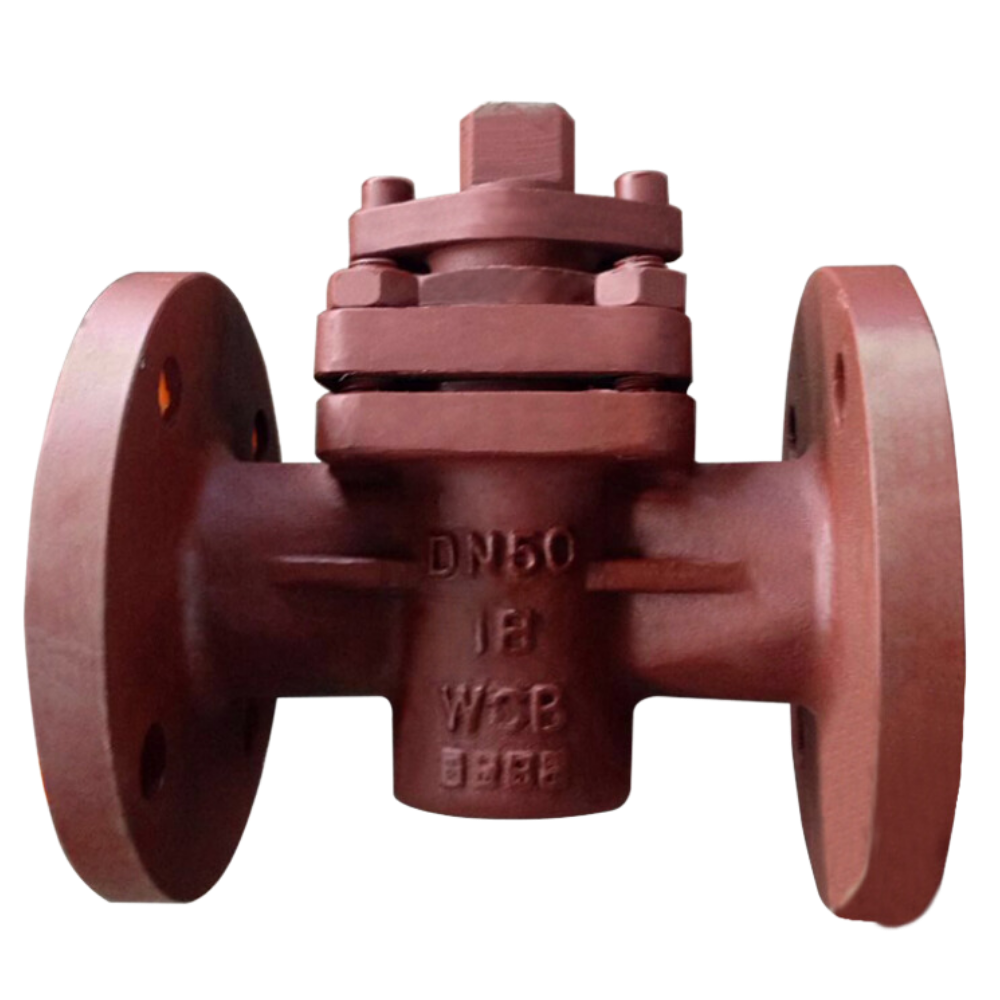

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]