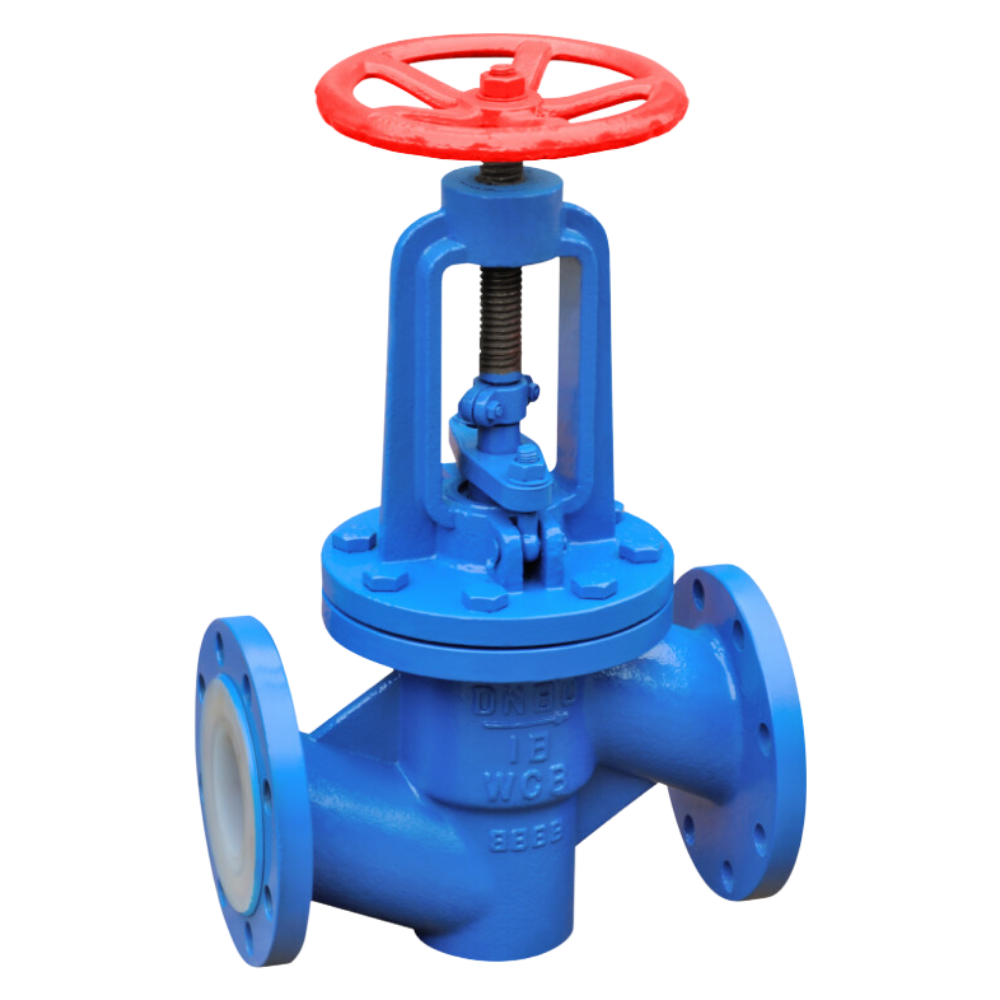

A fluorine-lined globe valve regulates the flow of corrosive fluids in industries such as chemical processing and water treatment. The internal surfaces are coated with fluorine to resist chemical corrosion. The valve works by moving a plug or disc within a seat to control the flow of fluid. This design allows precise flow and pressure […]