A fluorine lined ball valve is designed for use in corrosive environments, featuring a lining made of materials like PTFE (polytetrafluoroethylene) or PFA (perfluoroalkoxy). This valve provides excellent resistance to aggressive chemicals, ensuring reliable sealing and zero leakage. Key features include a full port design for minimal fluid resistance, making it suitable for on-off or control applications. The valve can handle a wide range of sizes (DN15 to DN350) and pressure ratings (Class 150 to PN40). Common applications include the chemical, petroleum, and pharmaceutical industries, where it effectively manages corrosive media.

| Name/Material | WCB | CF8 | CF3 | CF8M | CF3M |

| Body | WCB | CF8 | CF3 | CF8M | CF3M |

| Ball/Stem | WCB | CF8 | CF3 | CF8M | CF3M |

| Lined | FEP / PFA / PO / PTFE | ||||

| Seat | PTFE / RPTFE | ||||

| Bolt/Nut | B7/2H | B8/8 | B8/8 | B8M/8M | B8M/8M |

| Design&Manufacture Standard | HG/T3704, GB/T12237 | API 6D | ||

| FTF Dimension Standard | HG/T3704, GB/T12221 | ASME B16.10 | ||

| Flange standard | HG/T20592, GB/T9119 | ASME B16.5, JIS B2220 | ||

| Inspection & Test Standard | HG/T13927, JB/T9092 | API 598 | ||

| Normal Diameter | DN15~DN350 | 1/2”~14” | ||

| Normal Pressure | 1.0MPa | 1.6MPa | 150LB | |

| Test pressure | Shell Test | 1.5MPa | 1.5MPa | 1.5MPa |

| High Pressure Test | 1.1MPa | 1.1MPa | 1.1MPa | |

| Low Pressure Test | 0.6MPa | 0.6MPa | 0.6MPa | |

| Temperature Range | FEP:-29℃~120℃, PFA:-29℃~180℃, PTFE:-29℃~150℃ | |||

| Applicable Medium | Strong corrosion medium: Hydrochloric acid, Nitric acid, Hydrofluoric acid, Liquid chlorine, Sulfuric acid and Aqua regia etc. | |||

| DN (mm | PNS (Inch) | L | D | D1 | D2 | f | b | Z-Φd | Do | H |

| PN1.0MPa/1.6MPa | ||||||||||

| 15 | 1/2 | 140 | 95 | 65 | 45 | 3 | 15 | 4-14 | 140 | 90 |

| 20 | 3/4 | 140 | 105 | 75 | 55 | 3 | 17 | 4-14 | 140 | 100 |

| 25 | 1 | 150 | 115 | 85 | 65 | 3 | 17 | 4-14 | 180 | 105 |

| 32 | 1-1/4 | 165 | 140 | 100 | 75 | 3 | 19 | 4-18 | 180 | 120 |

| 40 | 1-1/2 | 180 | 150 | 110 | 85 | 3 | 19 | 4-18 | 225 | 140 |

| 50 | 2 | 200 | 165 | 125 | 100 | 3 | 21 | 4-18 | 225 | 150 |

| 65 | 2-1/2 | 220 | 185 | 145 | 120 | 3 | 21 | 4-18 | 360 | 160 |

| 80 | 3 | 250 | 200 | 160 | 135 | 3 | 21 | 8-18 | 420 | 215 |

| 100 | 4 | 280 | 220 | 180 | 155 | 3 | 23 | 8-18 | 420 | 240 |

| 125 | 5 | 320 | 250 | 210 | 185 | 4 | 24 | 8-18 | 520 | 250 |

| 150 | 6 | 360 | 285 | 240 | 210 | 4 | 26 | 8-23 | 520 | 290 |

| 200 | 8 | 400 | 340 | 295 | 265 | 4 | 26 | 8/12-23 | 240 | 340 |

| 250 | 10 | 450 | 395 | 350 | 320 | 4 | 28 | 12-23/26 | 240 | 380 |

The fluorine lined valve of Lianke valve solves the application of strong acid and strong base organic solvent medium in chemical industry.Long service life,low application cost.

Designed with premium fluorine linings—FEP, PFA, or PTFE—our ball valve effortlessly handles aggressive media like hydrochloric acid, nitric acid, liquid chlorine, and aqua regia. The superior corrosion resistance ensures longevity, reducing the need for frequent replacements and lowering maintenance costs.

Covering a wide range of diameters (DN15~DN350, 1/2”~14”) and pressure ratings (1.0MPa, 1.6MPa, 150LB), this valve meets various industrial standards (HG/T3704, GB/T12237, API 6D), making it suitable for diverse applications in industries like chemical processing, petrochemical, and more.

Our fluorine-lined ball valve is manufactured to the highest standards (ASME B16.10, GB/T12221), ensuring precision and reliability. The valve’s robust body material options (WCB, CF8, CF3, CF8M, CF3M) further enhance its durability, while the advanced sealing technology guarantees a leak-free operation.

Designed to perform under extreme conditions, this valve operates efficiently across a wide temperature range:

FEP: -29℃ to 120℃

PFA: -29℃ to 180℃

PTFE: -29℃ to 150℃

This makes it ideal for both low and high-temperature applications, offering versatility in various industrial processes.

Our ball valve’s design adheres to major global standards (HG/T20592, ASME B16.5, JIS B2220), ensuring seamless integration into your existing systems. The valve’s user-friendly design also simplifies maintenance, further reducing downtime and operational costs.

A weir-type diaphragm valve is a specific design of diaphragm valve that features a raised lip or saddle in the valve body. The diaphragm comes into contact with this weir to form a seal and control fluid flow. Main parts and materials Name/Material CI WCB CF8 CF3 CF8M CF3M Body CI WCB CF8 CF3 CF8M CF3M Diaphragm […]

A straight-through diaphragm valve controls fluid flow in a pipeline using a diaphragm that moves vertically to open or close the flow path. The straight-through design allows fluid to pass directly through the valve, reducing pressure drop and maintaining efficient flow. It is commonly used in applications where reliable sealing and minimal obstruction are needed, […]

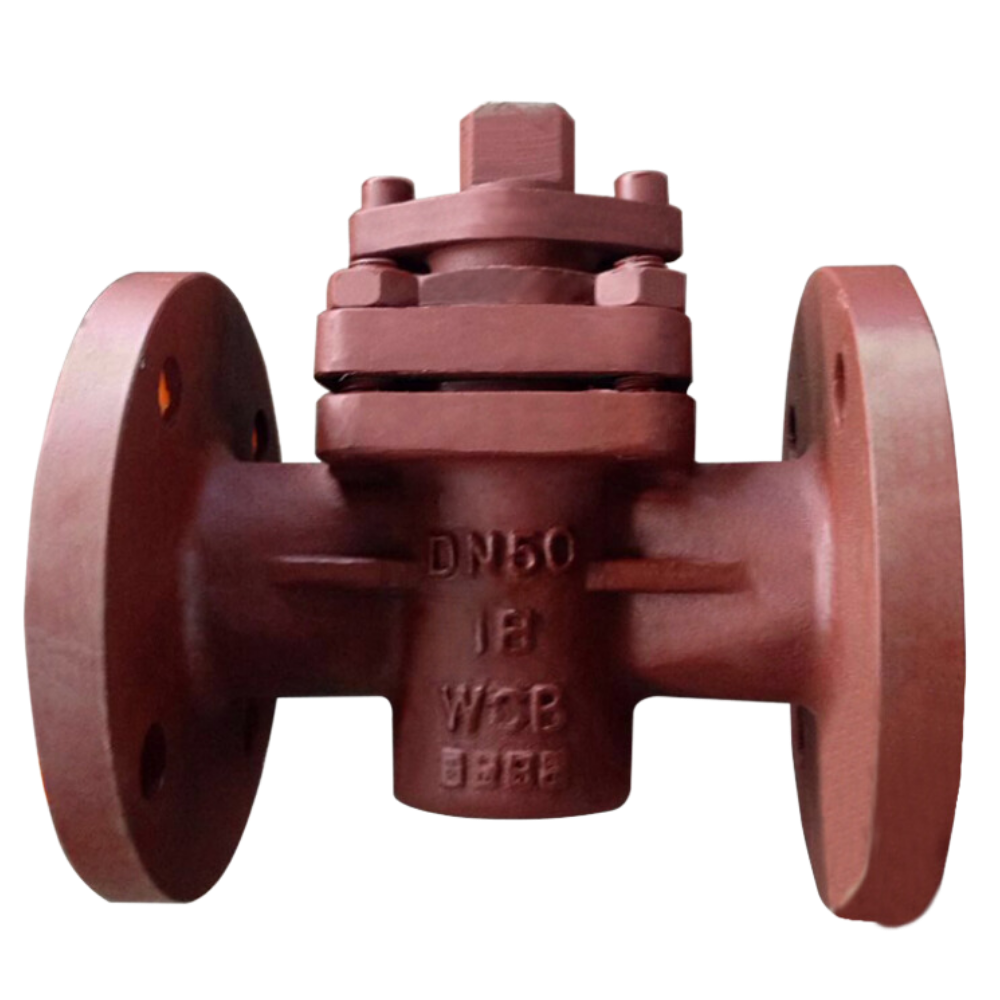

A plug valve controls fluid flow in a pipeline using a cylindrical or tapered plug with a central hole. The plug rotates within the valve body to open or close the flow path. When the plug aligns with the pipeline, fluid passes through. When turned so the hole is perpendicular to the flow, it blocks […]

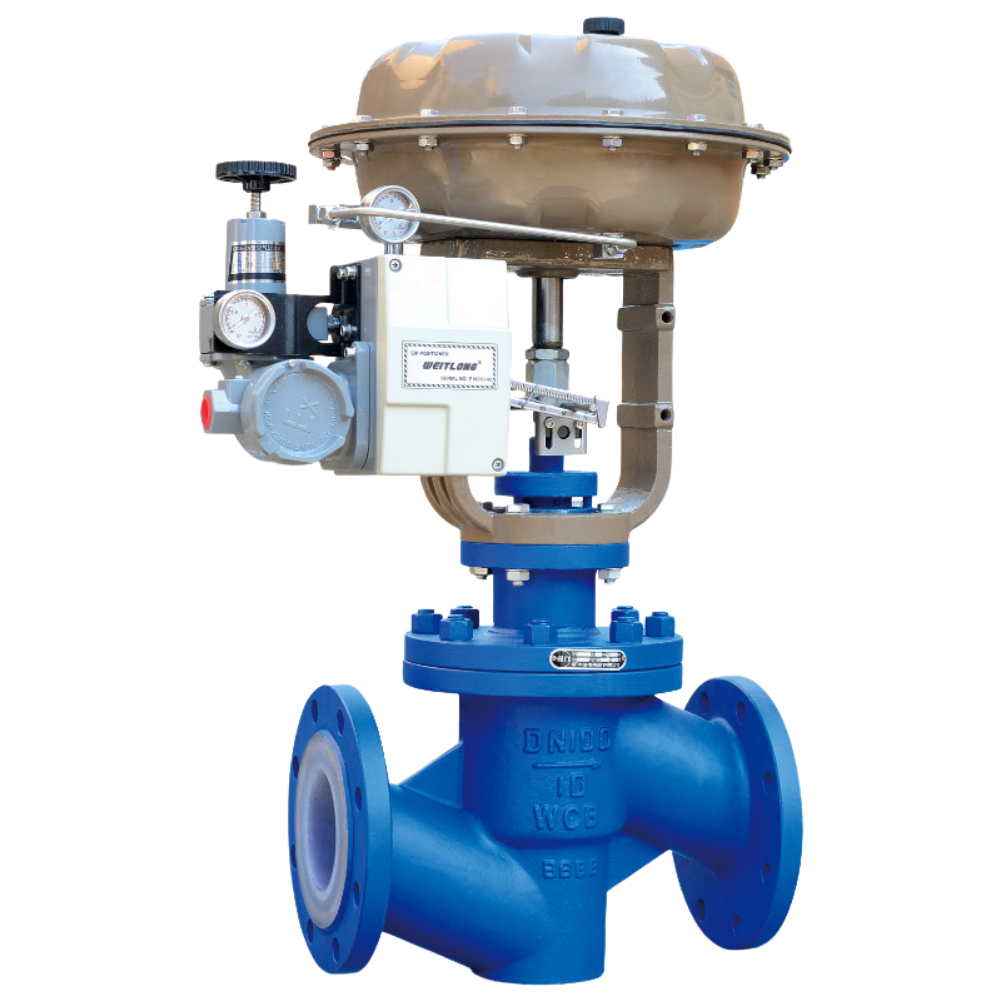

A fluorine lined control valve regulates the flow of fluids in a pipeline, adjusting flow rate, pressure, and temperature. It works by changing the size of the flow passage using elements like plugs, balls, or diaphragms. Control valves are crucial in industrial processes for maintaining operating conditions and ensuring system efficiency. They can be operated […]