Choosing the right basket strainer for your system comes down to understanding filtration size, strainer mesh, and how these elements fit into your specific piping setup. Whether you’re working in chemical processing, food production, water treatment, or HVAC, the right strainer ensures system protection, flow efficiency, and long-term equipment performance. This article will help you […]

Pinch valves are unique flow control devices that regulate the movement of fluids by pinching a flexible tube or sleeve within the valve. Unlike other valves that rely on mechanical parts like discs or gates to block or allow flow, pinch valves use a simple squeezing action to control the fluid. This makes them ideal […]

The most compelling difference between a butterfly valve and a gate valve is their operation mechanism. A butterfly valve uses a rotating disc to regulate or stop fluid flow, which provides quick and efficient control, especially for throttling. In contrast, a gate valve operates by lifting or lowering a gate to open or close the […]

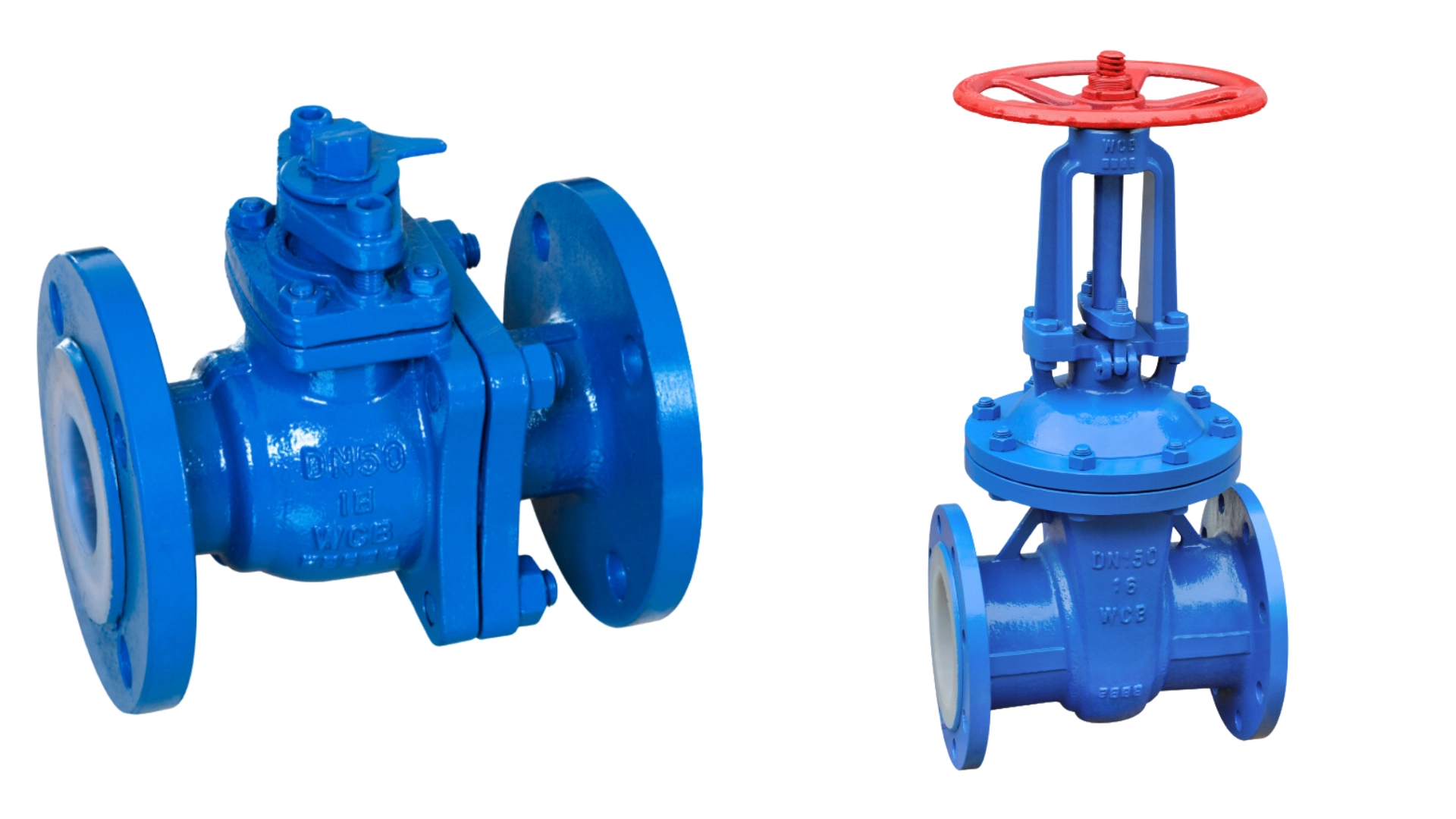

The most compelling difference between gate valves and ball valves is their mechanism for controlling flow. A gate valve uses a sliding gate to block or allow fluid passage, which makes it better suited for fully open or closed positions but less ideal for throttling. In contrast, a ball valve features a rotating ball with […]

Gate valves control fluid flow in various industrial applications. They can completely stop or allow flow, depending on the valve’s position. Valves, in general, share the same function — but what makes gate valves different? This article will explore what gate valves are, how they work, their components, types, and common issues, among other important […]

Check valves are essential components in many fluid systems as they are designed to allow flow in one direction and prevent backflow. For example, in a water supply system, a check valve ensures that contaminated water doesn’t flow back into the clean water supply — safeguarding the water quality and preventing potential health hazards. Today, […]

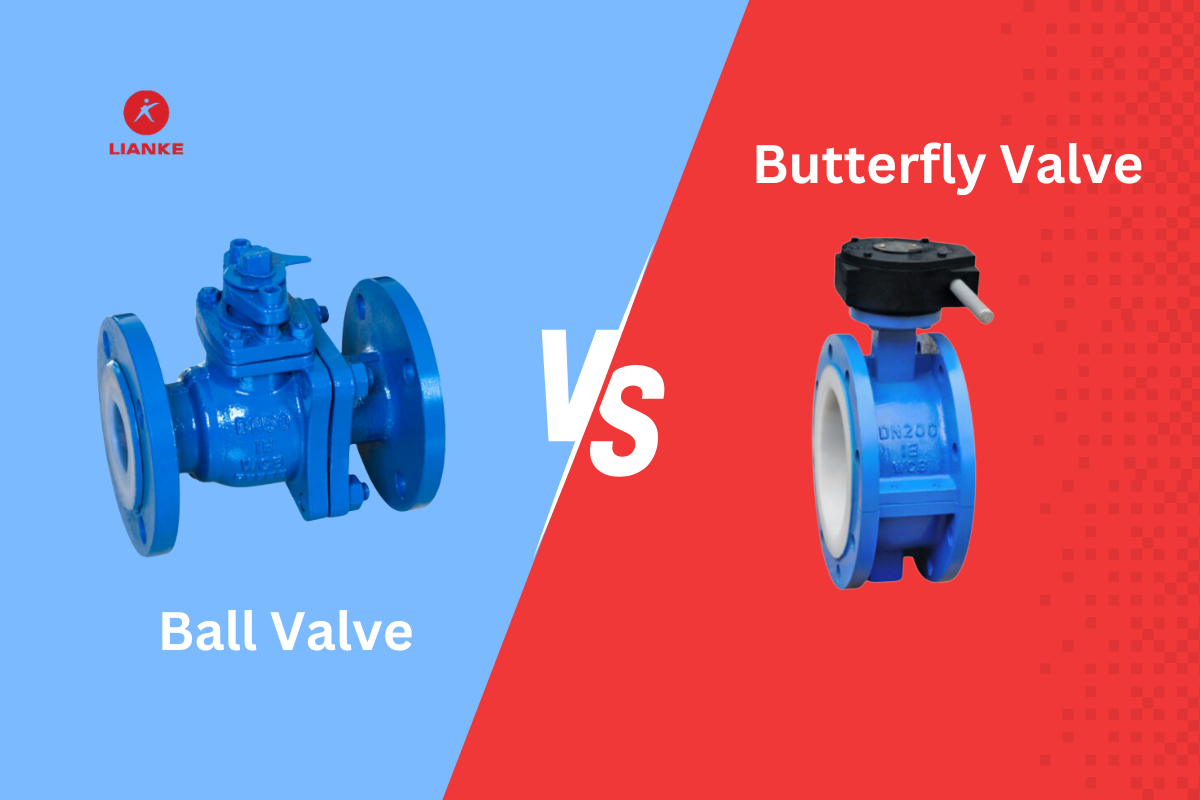

The greatest difference between a ball and butterfly valves lies in their design and flow control mechanism. A ball valve uses a spherical ball with a hole through its center to control flow — providing a full, unobstructed passage when open and a tight seal when closed. In contrast, a butterfly valve uses a rotating […]

Actuated valves provide automated control over the flow of liquids, gases, or other materials. Their key function is to regulate the opening and closing of a valve based on external signals. These signals trigger actuators, devices that convert energy into mechanical motion — allowing the valve to either open, close, or modulate the flow within […]

A pneumatic valve is a type of valve that operates using compressed air as its power source. When the air is introduced to the valve, it generates the force needed to move the internal components and control the flow of various media, such as liquids, gases, or slurries. In this article, you’ll learn about what […]

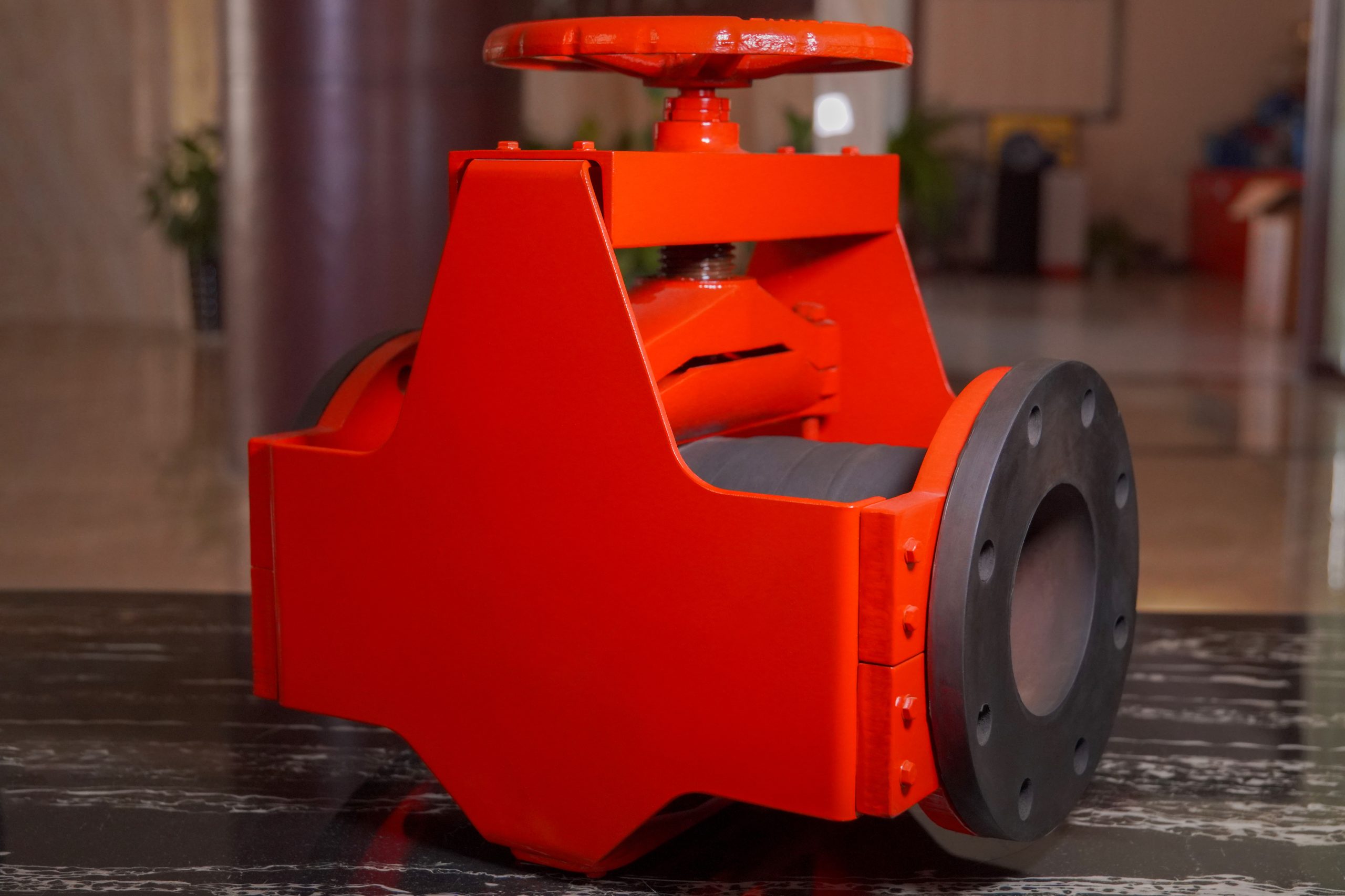

Fluid flow in industries is often controlled using pinch valves. These pinch valves control opening/closing by applying a force at the center of the valve. This forces the valve to close and blocks flow. The force applied on these rubber lined valves is done through different actuation types. Additionally, the internal rubber lining allows the valve […]