Choosing the right basket strainer for your system comes down to understanding filtration size, strainer mesh, and how these elements fit into your specific piping setup. Whether you’re working in chemical processing, food production, water treatment, or HVAC, the right strainer ensures system protection, flow efficiency, and long-term equipment performance. This article will help you […]

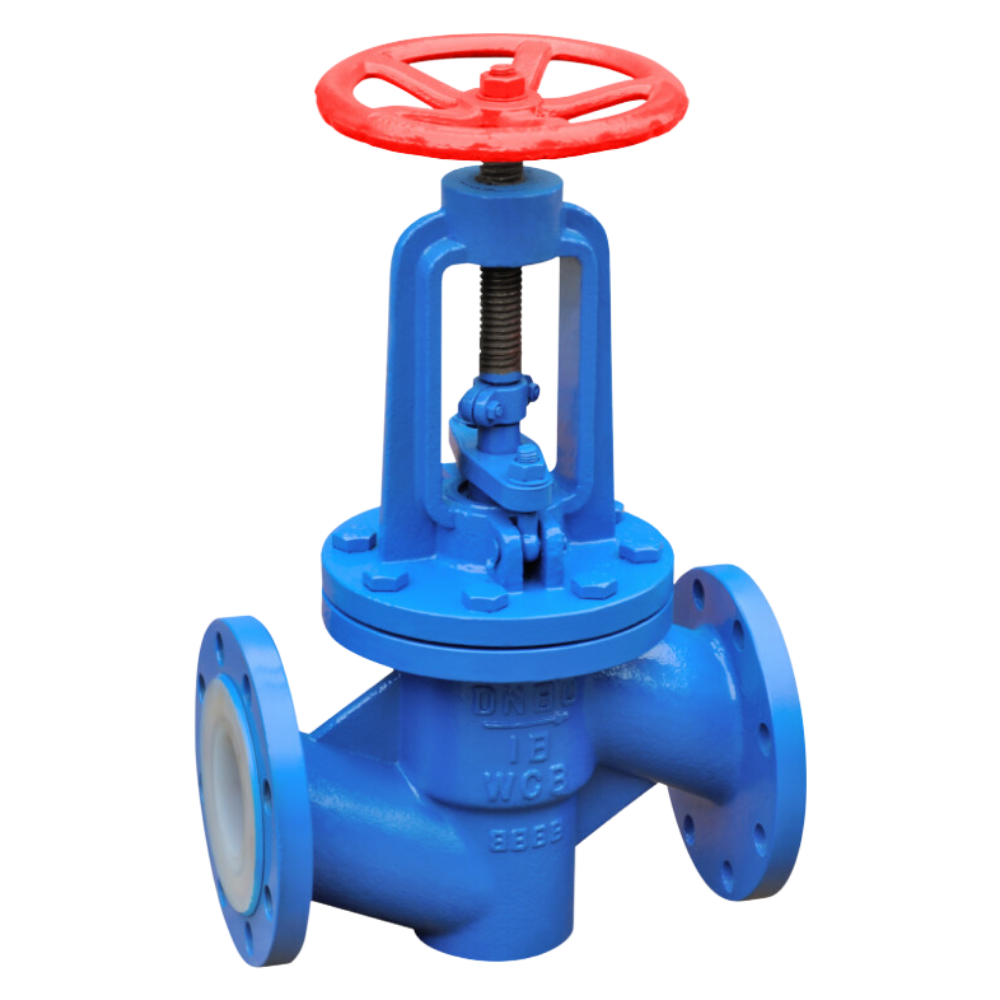

From delivering purified water in a pharmaceutical lab to controlling the flow of corrosive chemicals in an industrial facility, diaphragm valves play a vital role in ensuring efficiency and safety. Known for their durability, tight sealing, and ability to handle diverse fluids, these valves are indispensable in many industries. Whether it’s a clean environment or […]

In industries like pharmaceuticals, food processing, and water treatment, ensuring the smooth flow of liquids, gases, or slurries is crucial to maintaining system efficiency and safety. Diaphragm valves stand out in these fields for their reliability, precision, and ability to handle a variety of substances, from clean water to corrosive chemicals. While they provide several […]

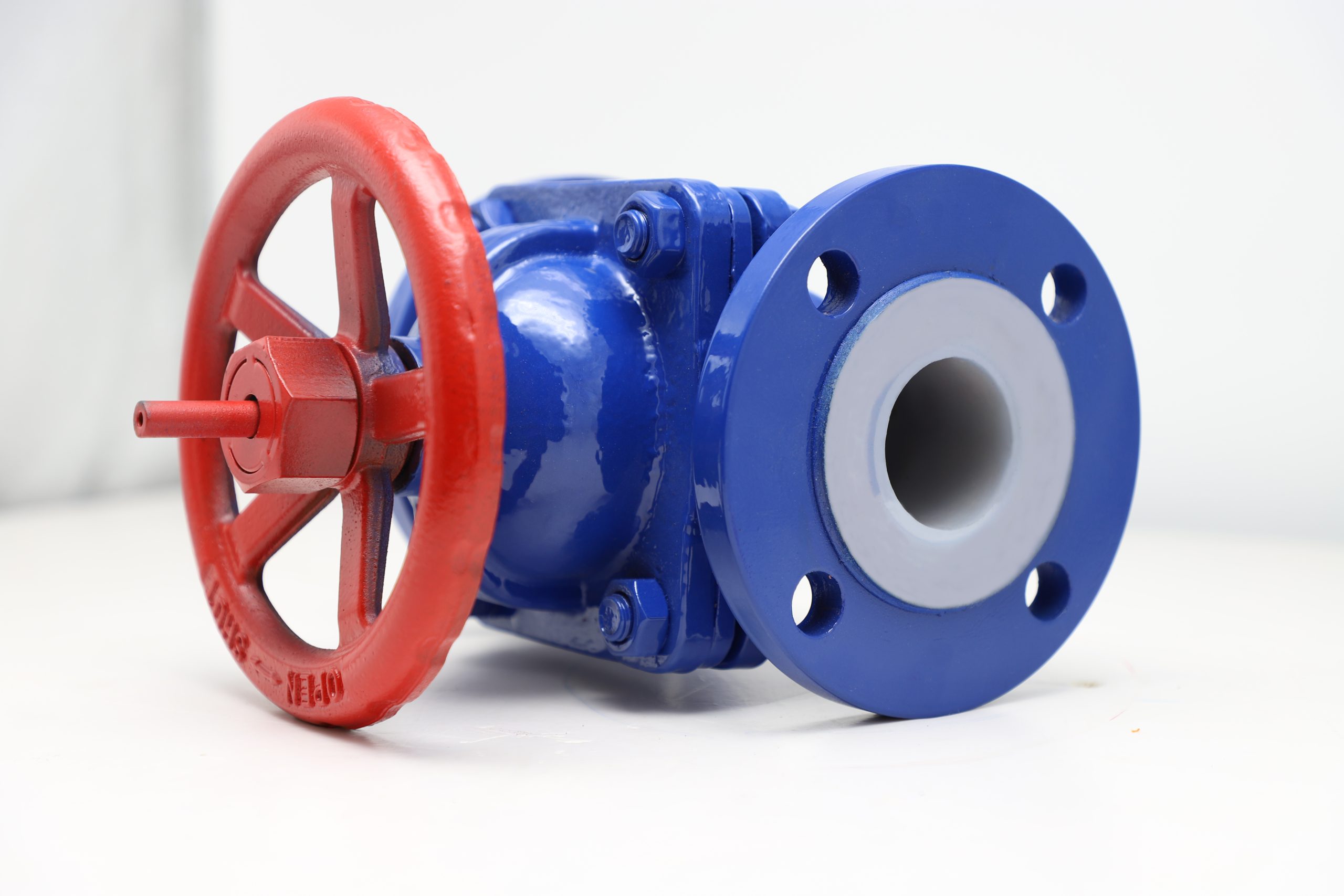

Diaphragm valves may not always be in the spotlight, but their role in controlling fluid flow is vital across various industries. These valves are designed with a flexible diaphragm that regulates the flow of liquids, gases, and semi-solids. From pharmaceuticals to water treatment, diaphragm valves provide precise control, tight shut-offs, and efficient fluid management. In […]

Diaphragm valves are indispensable in industries requiring precise fluid control and contamination-free operations. These valves excel in applications like water treatment, pharmaceuticals, and chemical processing, ensuring reliability and durability. Selecting the right diaphragm valve supplier is essential to meet your specific system needs. Here’s a comprehensive guide to the Top 10 Diaphragm Valve Manufacturers in […]

Picture this: a pipe bursts in your home, and water gushes everywhere. What’s the first thing you need? A stop valve. From homes to factories, stop valves provide the ability to shut off water, steam, or other liquids in emergencies or routine maintenance. But stop valves aren’t just for crisis control—they play a vital role […]

In industrial fluid systems, proper filtration is vital to protect equipment from debris and contaminants. Y strainers and T strainers are two common types of pipeline strainers used to ensure clean fluid flow. While both serve the same purpose, their design and application differ significantly. This article explores the key distinctions between Y strainers and […]

Strainers are essential in protecting equipment by filtering out debris and impurities in pipelines. However, not all strainers are created equal. With a variety of options, the Y-type strainer and duplex basket strainer stand out as popular choices. Now, you may be asking, “Which strainer is best for my needs?” Explore this guide to discover […]

Understanding the Essential Component of Industrial Filtration Bag filter housings are commonly used in industries to eliminate particulates from liquids without compromising the industrial process. However, structures that are designed to hold a filter bag, which acts as the barrier, are also specialized tools for contaminated particle collection. Especially in industrial applications, bag filter housing […]

Lined ball valves feature a protective lining that offers superior corrosion resistance and can handle a wider range of temperatures, making them ideal for aggressive chemical applications. In contrast, unlined ball valves are typically made from metal and may require additional coatings for protection, leading to more frequent maintenance and a shorter lifespan in harsh […]