Our pinch valve sleeve materials currently include Linke’s patented 38-series Nadiflex composite rubber, Q-grade NR natural rubber jointly sourced from Lanxess and Mitsui, EPDM ethylene propylene rubber, SI6501 high molecular silicone rubber, and NBR nitrile rubber. Additionally, we offer specialized pinch valve sleeve materials such as Hypalon rubber, CR-grade chloroprene rubber, and B-grade IIR butyl […]

Our pinch valve sleeve materials currently include Linke’s patented 38-series Nadiflex composite rubber, Q-grade NR natural rubber jointly sourced from Lanxess and Mitsui, EPDM ethylene propylene rubber, SI6501 high molecular silicone rubber, and NBR nitrile rubber. Additionally, we offer specialized pinch valve sleeve materials such as Hypalon rubber, CR-grade chloroprene rubber, and B-grade IIR butyl […]

Our pinch valve sleeve materials currently include Linke’s patented 38-series Nadiflex composite rubber, Q-grade NR natural rubber jointly sourced from Lanxess and Mitsui, EPDM ethylene propylene rubber, SI6501 high molecular silicone rubber, and NBR nitrile rubber. Additionally, we offer specialized pinch valve sleeve materials such as Hypalon rubber, CR-grade chloroprene rubber, and B-grade IIR butyl […]

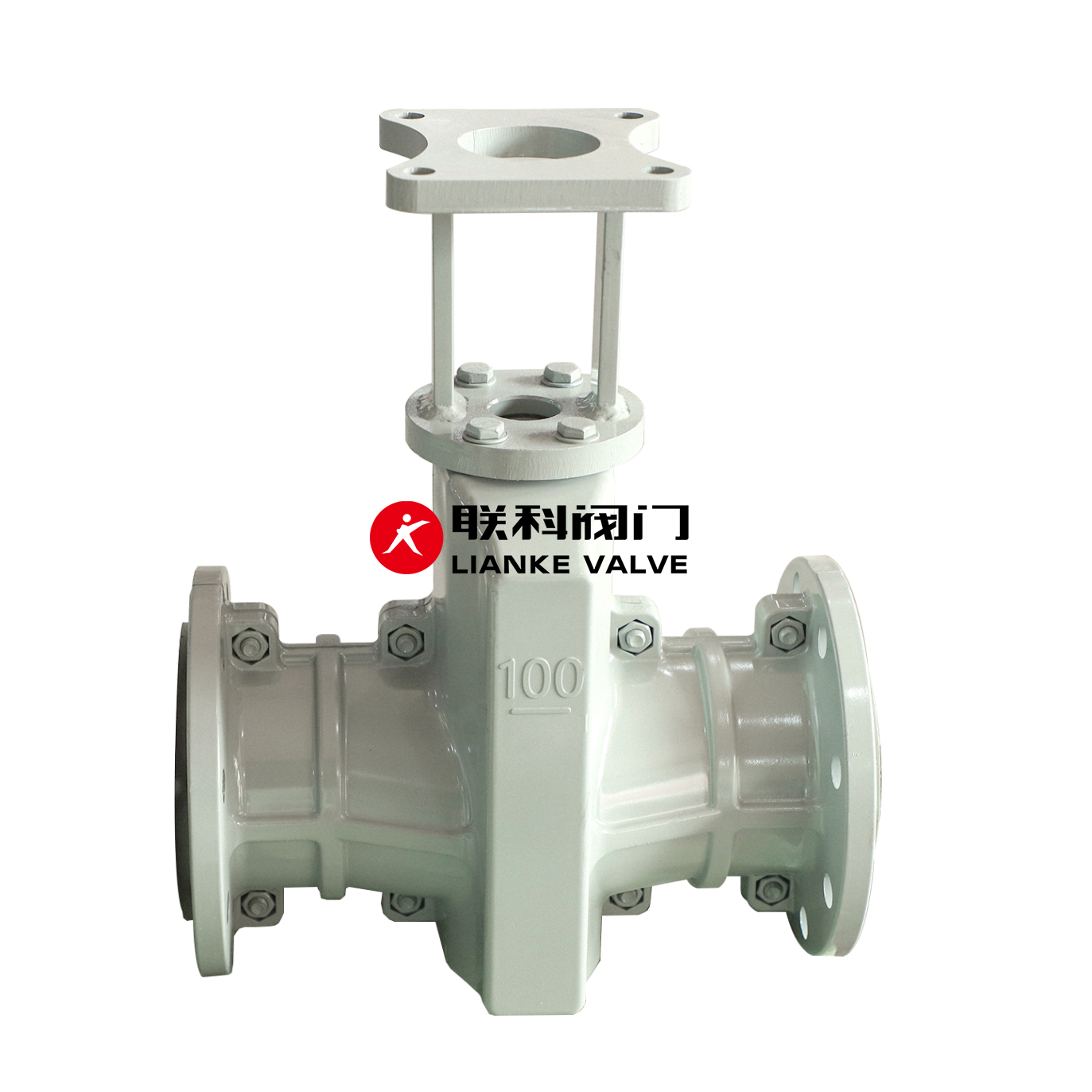

Our DN100 manual pinch valve offers efficient, low-maintenance flow control for abrasive and corrosive media. This pinch valve features a robust design, easy operation, and long-lasting rubber sleeve. Ideal for industrial pipelines, the DN100 pinch valve ensures reliable shut-off. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle […]

An electric pinch valve is a type of valve that uses an electric actuator to control the opening and closing of a flexible elastomer sleeve or tube, effectively regulating the flow of various media. Main of components Body, Electric Actuator, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the […]

Our DN25 manual pinch valve is designed for tough industrial applications, offering excellent control of abrasive and corrosive media, ensures reliable sealing, minimal maintenance, and long service life. Ideal for slurry, chemical, and wastewater systems. Main of components Body, sleeve, Stem, pinch rod, side guide rod, Hand wheel etc. Working principle when rotate the handle […]