If you work with industrial valves, you’ve likely heard of ASME B16.34—a critical standard that ensures valves perform safely under extreme conditions. Whether you’re an engineer designing a pipeline or a mechanic maintaining a chemical plant, understanding this standard is key to avoiding costly failures. In this guide, we’ll break down what ASME B16.34 entails, why it matters, and how it impacts valve selection and safety.

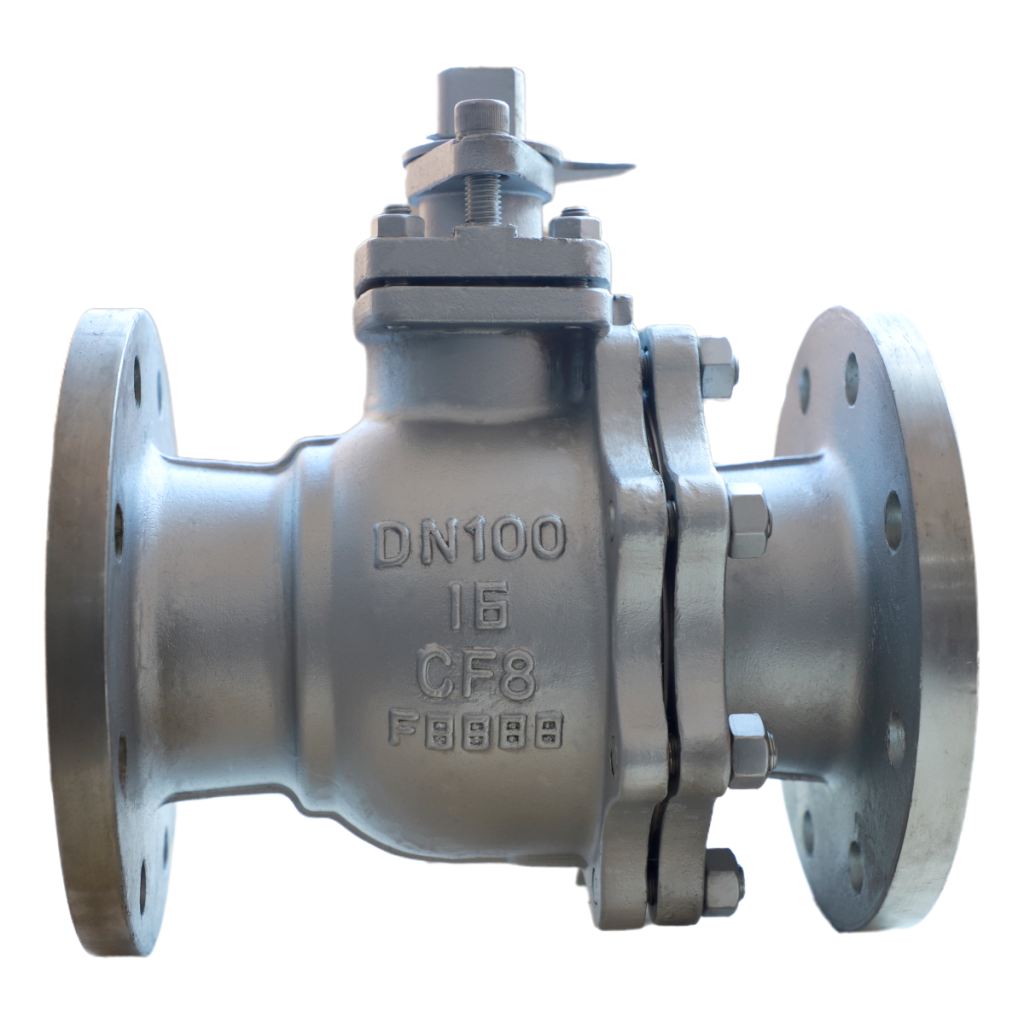

ASME B16.34 is a set of guidelines published by the American Society of Mechanical Engineers (ASME) that defines how industrial valves should be designed, built, and tested. It applies to valves made from materials like steel, stainless steel, and nickel alloys, and covers common types such as gate, globe, check, and ball valves.

The standard is mandatory for valves used in high-pressure systems, including oil and gas pipelines, power plants, and chemical processing facilities. Compliance ensures valves can handle the stress of extreme temperatures and pressures without leaking or breaking.

Every valve built to ASME B16.34 must meet specific pressure-temperature (P-T) ratings based on its material. These ratings determine the maximum pressure a valve can withstand at a given temperature. For example:

The standard provides detailed tables (like the one below) to help engineers match valves to their system’s needs.

| Material | Pressure Rating at 100°F (psi) | Pressure Rating at 500°F (psi) |

|---|---|---|

| Carbon Steel | 2,000 | 1,200 |

| Stainless Steel | 2,500 | 1,800 |

| Nickel Alloy | 3,000 | 2,500 |

Source: ASME B16.34-2017, Emerson Pressure-Temperature Guide

The standard specifies:

For instance, flanged valves must align with ASME B16.5 flange standards to avoid misalignment during installation.

ASME B16.34 lists approved materials for valve construction, such as:

Using the wrong material can lead to cracks or corrosion. A carbon steel valve in a chlorine service, for example, would degrade rapidly.

All valves must pass rigorous tests, including:

These tests are outlined in ASME B16.34 Section 8 and are critical for safety.

Valves built to ASME B16.34 are trusted in industries where failure isn’t an option:

A 2017 update to the standard (B16.34-2017) added requirements for forged and fabricated valves, expanding its use in modern manufacturing (Valve Magazine).

While ASME B16.34 focuses on design and testing, other standards cover specific valve types or applications:

| Standard | Scope | Key Difference |

|---|---|---|

| API 6D | Pipeline valves (oil/gas) | Focuses on full-bore flow design |

| ISO 5208 | Industrial valve testing | Less stringent pressure ratings |

| ASME B16.10 | Face-to-face valve dimensions | Doesn’t cover materials or testing |

Source: Wermac, Piping Tech

ASME B16.34 is often used alongside these standards. For example, a pipeline valve might meet both API 6D and ASME B16.34 for full compliance.

ASME B16.34 isn’t just a technical document—it’s a roadmap for building valves that keep industrial systems safe and efficient. By specifying materials, designs, and tests, it ensures valves perform reliably in the toughest environments. For engineers and technicians, understanding this standard means fewer breakdowns, lower maintenance costs, and safer workplaces.

For more details, refer to the official ASME B16.34-2017 PDF or consult resources like Valve Magazine.

If you work with industrial valves, you’ve likely heard of ASME B16.34—a critical standard that ensures valves perform safely under extreme conditions. Whether you’re an engineer designing a pipeline or a mechanic maintaining a chemical plant, understanding this standard is key to avoiding costly failures. In this guide, we’ll break down what ASME B16.34 entails, why […]

Plastics and elastomers are essential materials in industries ranging from automotive manufacturing to medical devices. While both are polymers (long chains of repeating molecules), their properties and applications differ significantly. This guide breaks down their technical distinctions, backed by industry research and data, to help you make informed material choices. 1. Plastics and Elastomers: Core […]

Valve lubricants serve as critical operational components in industrial systems, preventing mechanical failures and maintaining functional integrity. Across sectors such as oil refining, water treatment, and chemical processing, valves regulate fluid and gas flow, with their operational reliability contingent on precise lubrication practices. This guide analyzes the technical necessity of valve lubricants, supported by empirical […]

In industrial systems, check valves are critical for preventing backflow, protecting equipment, and maintaining process efficiency. However, improper installation can lead to premature wear, leaks, or even system failure. For engineers, mechanics, and technicians, understanding the technical nuances of check valve installation is essential. This guide breaks down key considerations, supported by industry standards and […]