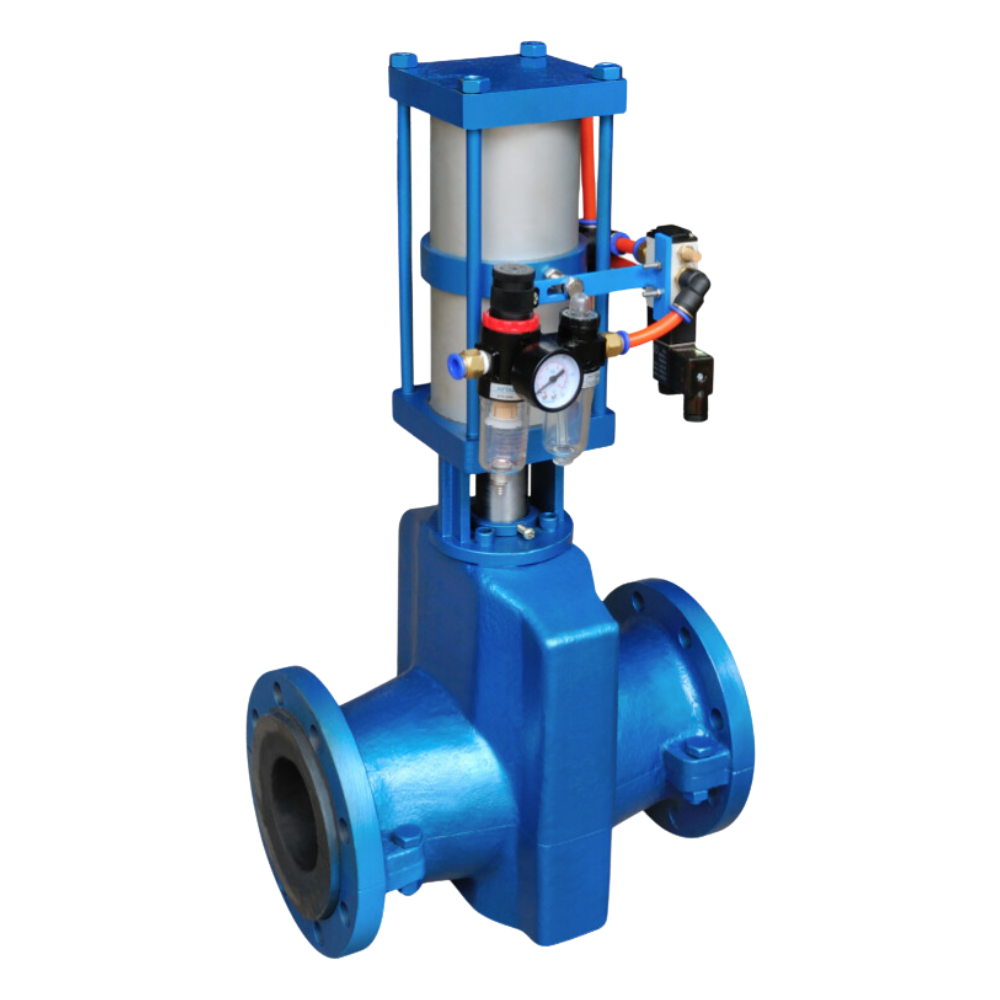

Pneumatic Pinch valves are fast-acting valves that control fluid flow. When left alone, these valves are open, allowing fluid flow. Pneumatic pinch valves use compressed air to pinch the elastomeric internal sleeve at the center to close the valve. Pinch valves are apt for operations that need to deal with grainy or corrosive fluids. And that’s why a lot of them can be found in many industries. Continue on to learn more about how pinch valves work.

Air operated valves or pneumatic valves are known to use compressed air to generate opening/closing movement. But pinch valves don’t work the same way. When left alone, the pinch valve is open. And under no pressure, the valves allow fluids to pass through. Closing the valve is where valve automation starts.

As mentioned, compressed air systems utilize compressed air to generate motion. The motion then opens the valve. In case of pinch valves, the compressed air is used to generate force on the center of the valve. This pinches the valve from the center, closing it and blocking fluid flow. It’ll help to understand that pinch valves have an internal elastomeric sleeve. So when air is used to generate the force, this sleeve is pushed/pinched to close the valve.

Pneumatic pinch valves offer the following benefits:

Pneumatic valve automation comes with the risk of system failures. To prevent these system failures from causing large scale operational damage, pneumatic pinch valves come with a protection circuit. If the compressed air, which closes the valve, runs out of power, the circuit continues to keep the valve closed. And once that happens, the valve cannot be reopened automatically. The valve can only be reopened manually.

This fail safe prevents any large scale damage to industrial pipes. For example, if the valves are closed to prevent the movement of fluids, the pneumatic actuation’s system failure will cause damage or unwanted fluid movement.

| Pneumatic Control Systems | Hydraulic Control Systems | Electric Control Systems | Manual Control Systems |

| Use compressed air to open/close valves. | Use hydraulic fluid to open/close valves | Use electricity to open/close valves | Use manual labor to open/close valves |

| Offer precise flow control | Can generate a lot of force | Offer great accuracy and response times | Difficult to achieve precise flow conditions |

| Generate a lot of force | Much heavier than other actuators | Can be difficult to integrate into working systems | Require no extra installations |

| Can be noisy | Very noisy | Little to no noise | No Noise |

| Require frequent Maintenance | Require routine maintenance | Doesn’t require frequent maintenance | Everyday use leads to frequent inspections |

Pneumatic pinch valves are used in chemical factories, pharmaceutical pipelines, food & beverage factories and the cement industry. This is because they are apt for carrying grainy/corrosive fluids and offering precise flow control.

Each actuated valve comes with fail safes to prevent large scale damage. If the external compressed air provider runs out of power, the pinch valves will remain closed with the help of a protection circuit. This circuit takes the place of compressed air and generates a force to close the valve.

Resources:

What is a Pinch Valve? Working, Types, Selection, and Advantages of a Pinch Valve – What Is Piping

Pinch Valve – How They Work | Tameson.com

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]