Due to the development of industrial applications, using butterfly valves for flow regulation has become the norm. In this article, we review the top five suppliers of butterfly valves, their major products and technologies used in their construction, which give them competitive advantages over other companies.

The professionals will find it useful to know the properties and fields of application of these valves to choose a proper solution for their operations. The differences in efficiency and safety brought about by these butterfly valves cover a variety of fields, including chemical processing and even water treatment. Understanding the top suppliers and their specialty products, and knowing how to choose the butterfly valve that best fits your needs will be the purpose of this guide.

| No. | Brand | Website | Country |

| 1 | Lianke | pinchlinedvalves.com | China |

| 2 | Flowserve | flowserve.com | USA |

| 3 | KSB SE | ksb.com | Germany |

| 4 | Bray | bray.com | USA |

| 5 | Crane | cranecpe.com | USA |

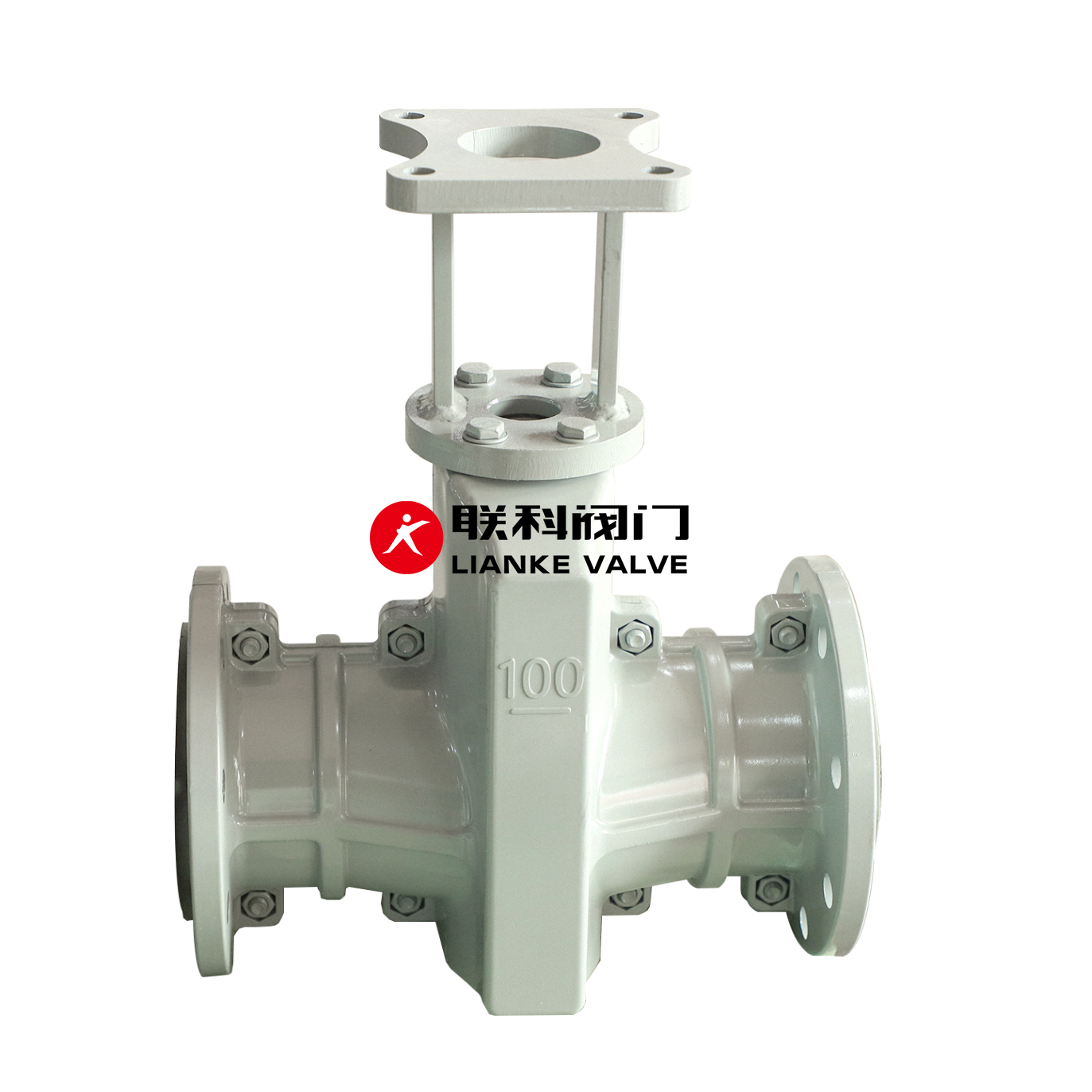

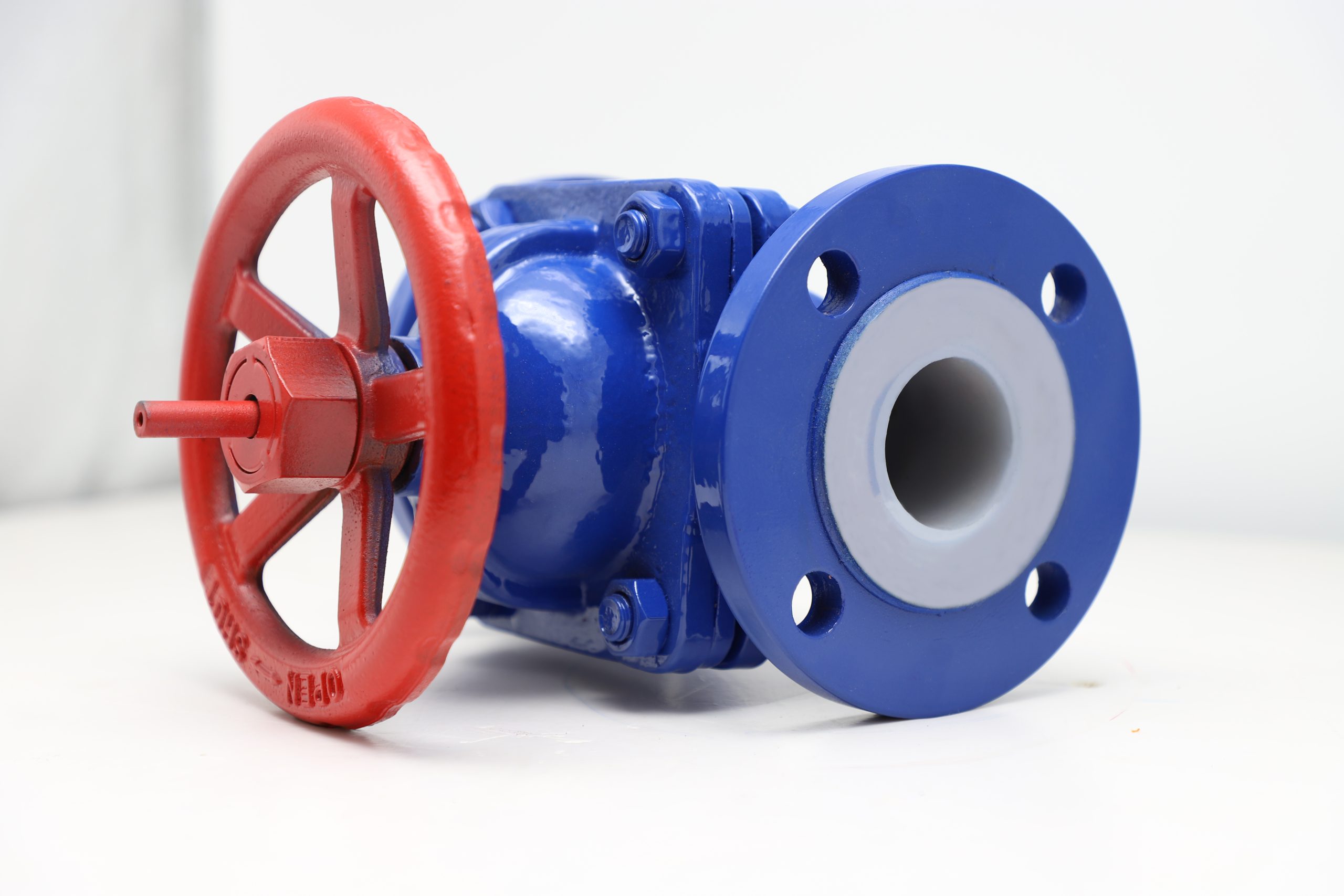

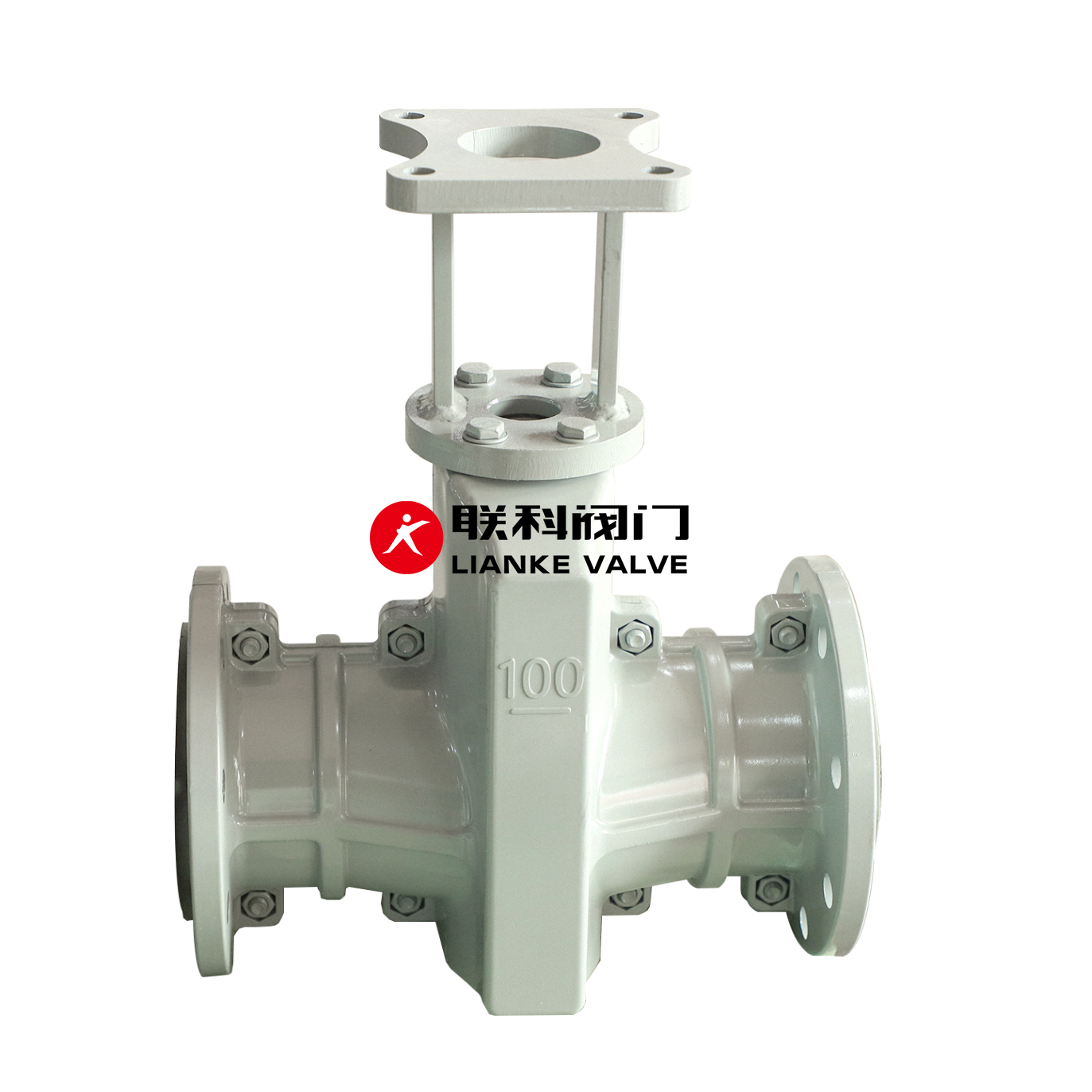

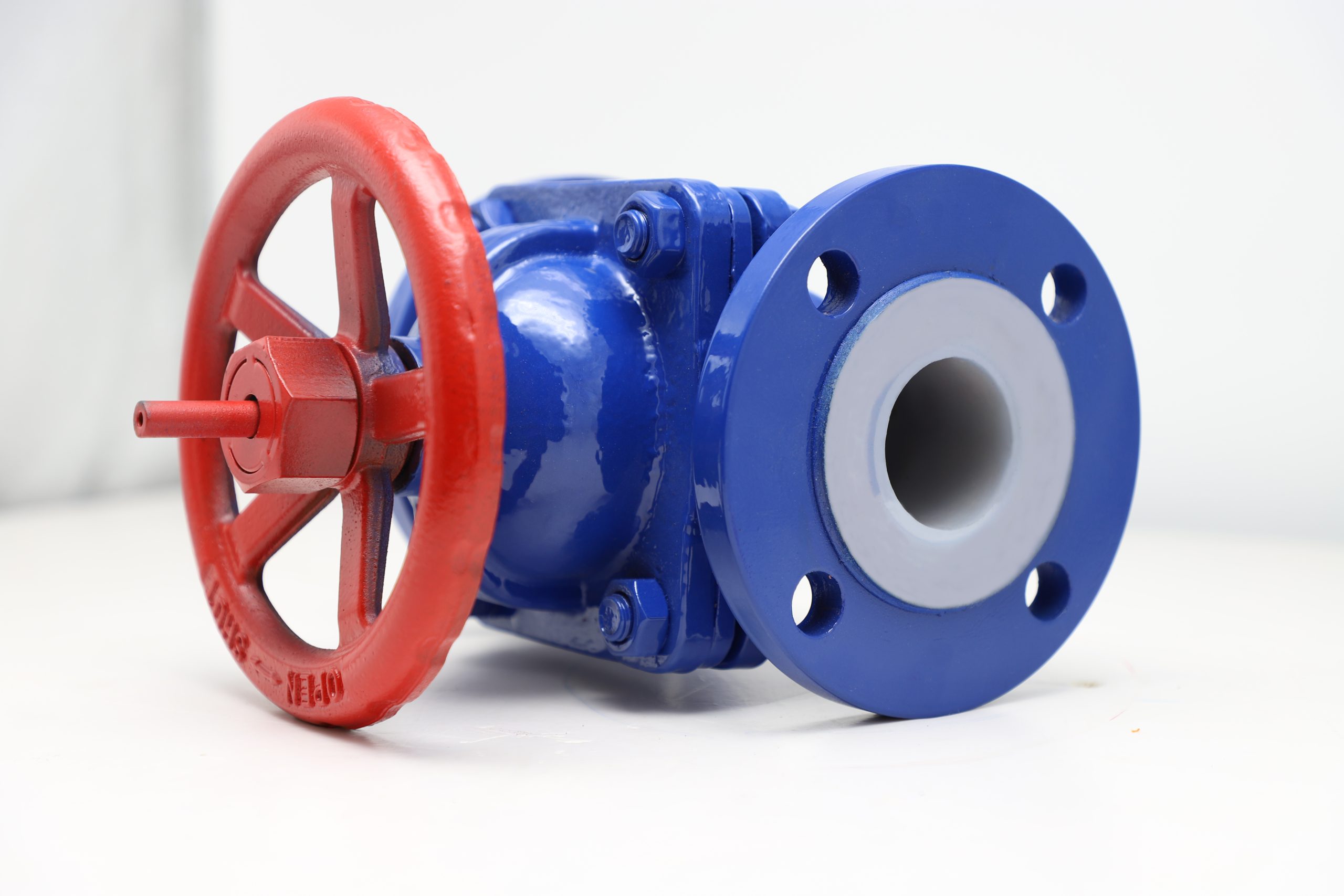

Lianke Valve’s Fluorine-lined butterfly valves are the best valves that protect even the most aggressive chemicals, including hydrochloric acid, nitric acid, and sulfuric acid. Their complete range covers sizes from DN40 to DN1200, which makes them useful in various sectors.

The manufacturers pay more attention to quality as they use quality materials for the valve bodies, such as WCB, CF8, CF3, CF8M, and CF3M that offer great strength and withstand difficult conditions. Their products comply with strict international requirements and have been thoroughly tested to ensure maximum performance.

Lianke Valve’s fluorine-lined butterfly valves have significant developments that enhance the technology for flow control in harsh applications. These valves blend robustness with an impressive variety of design features to ensure reliable performance within demanding industrial applications.

The fluoropolymer lining technology provided by Lianke Valve offers advanced safety against aggressive chemicals. The valve body lined with PTFE blocks the aggressive media from making contact with the valve core parts, thus significantly increasing the working life and decreasing the need for maintenance.

These valves can be conventionally applied in the following industrial domains:

The butterfly valves made by Lianke also meet the requirements of international standards:

The design involves incorporating the following into the valve:

These arrangements guarantee dependable performance in demanding applications, while operation and maintenance remain straight-forward. Combining advanced materials and high-precision engineering, the fluorine-lined butterfly valves of Lianke are the best for industries where highly corrosive media are present and operational reliability is the focus.

There are many factors that must be taken into account when choosing a supplier of butterfly valves to obtain the best quality and durability. Lianke Valve is unique because it offers fluorine linings that are tailored to certain applications in the industry.

The choice of a butterfly valve depends mostly on the pivotal operating parameters:

Specific industries have specific preferences regarding valve features:

The ball valve industry is still developing, and companies such as Lianke Valve are helping to innovate with:

The internal fluorine lining is useful since it adds anti-corrosive and abrasion-resistant properties.

Separates the valve body from the media inside the valve.

Significantly increases the overall service life of the valve.

Simple manual actuators for basic construction.

Electric types for automated control systems.

Pneumatic types for specific applications.

FEP: -29℃ to 120℃

PFA: -29℃ to 180℃

PTFE: -29℃ to 150℃

It is important to choose the correct supplier of butterfly valves so that the butterfly valves can function well in different fields. Lianke Valve’s fluorine-coated butterfly valves show the successes in the valves construction. These valves have high resistance to corrosion and high reliability. As the industries have new demands, there is always a management for suppliers like Lianke, who can and do fulfill them with modifications for special operations.

As for others who would want to further extend their knowledge about butterfly valves and processes where these valves are used, such resources are provided. You can improve your operations by using Lianke Valve’s products and learn what they offer by visiting their product page. Follow the butterfly valve market so you can always find something interesting and make the right choice in the industrial valve that will meet your requirements.

What is a Pinch Valve? A pinch valve is a control valve that utilizes pressurized air to manage fluid flow. Pinch valves are also referred to as squeeze valves or clamp valves. It is a cost-effective option due to its simplicity and low friction, making it resistant to clogging. Pinch valves find applications in on/off […]

From delivering purified water in a pharmaceutical lab to controlling the flow of corrosive chemicals in an industrial facility, diaphragm valves play a vital role in ensuring efficiency and safety. Known for their durability, tight sealing, and ability to handle diverse fluids, these valves are indispensable in many industries. Whether it’s a clean environment or […]

In industries like pharmaceuticals, food processing, and water treatment, ensuring the smooth flow of liquids, gases, or slurries is crucial to maintaining system efficiency and safety. Diaphragm valves stand out in these fields for their reliability, precision, and ability to handle a variety of substances, from clean water to corrosive chemicals. While they provide several […]

Diaphragm valves may not always be in the spotlight, but their role in controlling fluid flow is vital across various industries. These valves are designed with a flexible diaphragm that regulates the flow of liquids, gases, and semi-solids. From pharmaceuticals to water treatment, diaphragm valves provide precise control, tight shut-offs, and efficient fluid management. In […]