Gate valves are essential in controlling fluid flow in pipelines. However, not all gate valves are the same—one key difference is whether they use a rising stem or a non-rising stem mechanism. Understanding this difference is crucial when selecting the right valve for your application.

In this guide, we’ll explain the differences between rising stem gate valves and non-rising stem gate valves, explaining their working mechanisms, advantages, disadvantages, and applications. Whether you’re an expert or just learning about valves, this guide will help you understand the key differences and make the right choice.

A rising stem gate valve has a stem that moves up and down visibly, making it easy to determine whether it is open or closed. The stem threads are located externally and shift upwards as the valve opens, simplifying maintenance and reducing internal wear.

A non-rising stem gate valve features an internal threaded mechanism where the stem turns to move the gate but remains in a fixed position. Since the motion occurs inside the valve body, it is well-suited for installations with limited vertical space, such as underground pipelines or compact mechanical rooms.

The following table highlights the key differences:

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

| Stem Movement | Moves up/down externally | Stays at a fixed height |

| Thread Location | External (on stem) | Internal (inside valve body) |

| Space Requirement | Needs more vertical space | Compact, ideal for confined spaces |

| Maintenance | Easy lubrication and visual inspection | Harder to inspect and lubricate |

| Corrosion Risk | Lower (external threads) | Higher (internal threads exposed to fluid) |

| Best Use Cases | Industrial plants, above-ground installations | Underground pipelines, tight spaces |

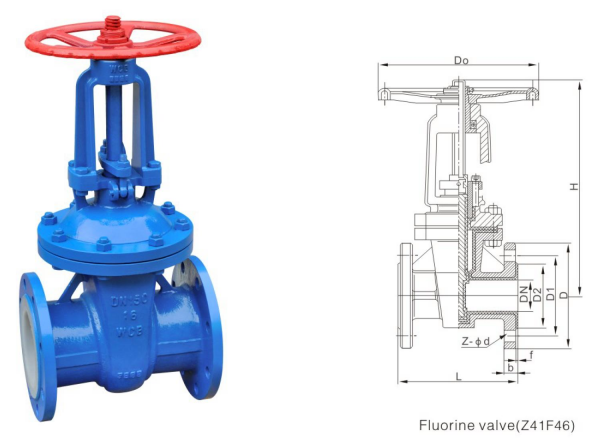

A gate valve where the stem does not move vertically but rotates internally to control the gate’s position. Ideal for limited-space installations.

The handwheel rotates the stem, moving the gate up or down without changing the stem’s external height.

The handwheel lifts the stem and gate together, providing a clear visual indicator of the valve’s status.

Choose a rising stem valve for above-ground applications where visibility and easy maintenance are needed. Choose a non-rising stem valve for underground or space-limited installations where a compact design is essential.

Choosing between a rising stem gate valve and a non-rising stem gate valve depends on your specific needs. If you require easy visual monitoring and maintenance, use a rising stem. If space-saving and underground installation are priorities, a non-rising stem is better.

Still unsure? Contact us today for expert guidance on selecting the right gate valve for your project!

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]