Have you ever wondered how to tell if a valve is open or closed? Knowing the valve’s status is crucial when dealing with a water valve open or closed, industrial piping, or home plumbing. Understanding how different valve types operate helps prevent leaks, pressure build-up, and system failures.

In this guide, we’ll explain the different types of valves, how to know if a valve is open or closed, and step-by-step methods to determine their status. You’ll also learn troubleshooting techniques for common valve issues. Let’s dive in.

Valves are essential components in various systems, controlling the flow of fluids and gases. Here’s how to identify if they are valve open closed, depending on the valve type.

Gate valves are commonly used in water and gas systems. They have a circular handwheel that raises or lowers an internal gate to allow or block flow.

Ball valves use a rotating ball with a hole to control fluid flow. They are among the easiest to read.

Ball valve open and closed positions:

Butterfly valves use a rotating disc to manage flow, with the lever indicating their status.

Globe valves adjust the flow by moving a plug against a seat, with the handwheel’s direction showing their state.

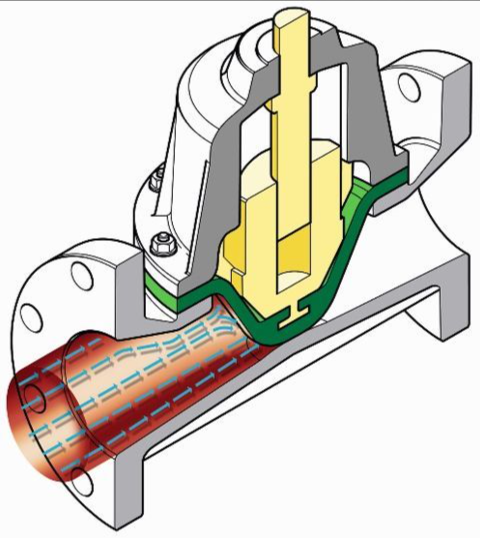

Check valves to prevent backflow and operate automatically.

If you’re unsure about a valve’s position, these detection methods can help confirm whether it is open and close valve.

A visual inspection is the quickest way to determine a valve’s status. Start by examining the handle or stem position—most valves follow a standard alignment where a handle parallel to the pipe means open, and a perpendicular handle means closed. Some valves, like gate valves, have a rising stem that visibly moves up when the valve opens. Industrial valves may also feature position indicators, such as a small gauge or marking, to show the exact state of the valve. Checking for labels or engravings on the valve body can also help confirm its position.

If the valve lacks visible indicators, alternative methods can be used.

For more precise monitoring, automated systems provide real-time valve position updates.

Using these methods, you can confidently determine if a valve is open or closed, preventing system malfunctions and ensuring smooth operation.

If a valve isn’t functioning correctly, these common issues and solutions can help restore optimal performance.

A valve can get stuck due to mineral deposits, corrosion, debris buildup, or mechanical wear. Over time, residue can accumulate inside the valve, making turning difficult. To resolve this, a penetrating lubricant must be applied to loosen the components. If the valve remains immobile, gently tap it with a rubber mallet or use a wrench to increase leverage. If none of these methods work, the valve may need to be replaced.

Leaks occur when seals wear out, fittings become loose, or the valve body develops cracks. A leaking valve can cause water loss, pressure issues, or system damage. The first step is to inspect the valve and tighten any loose connections. If the problem persists, replace O-rings or gaskets to restore a proper seal. In cases where the valve body is cracked or severely damaged, replacing the entire unit is the best solution.

Corrosion happens when a valve is exposed to moisture, chemicals, or harsh environmental conditions for extended periods. This can weaken the structure and reduce efficiency. Use valves from corrosion-resistant materials such as stainless steel or brass to prevent corrosion. Additionally, applying protective coatings and performing regular maintenance can help prolong the valve’s lifespan.

Incorrect labeling can lead to operational errors and safety hazards, especially in complex systems. Mislabeled valves usually result from installation mistakes or oversight during maintenance. Use durable, weather-resistant labels that indicate the valve’s status to prevent confusion. Verifying labels regularly and updating them when necessary is essential to ensure accurate identification.

A partially closed valve can disrupt flow and cause pressure fluctuations in the system. This typically occurs due to obstructions, improper operation, or mechanical faults. Check for blockages restricting movement if a valve does not fully open or close. Ensure the handle or actuator is functioning correctly. If resistance is encountered, the internal mechanism may require maintenance or replacement.

Check if the handle is aligned with the pipe. If it’s parallel, the valve is open. If it’s perpendicular, the valve is closed.

A parallel handle means open, and a perpendicular handle means closed for ball and butterfly valves. For gate and globe valves, turning counterclockwise opens the valve.

Partial closure restricts flow and may cause pressure buildup, inefficiency, or damage over time. Use a valve suited for throttling, like a globe valve.

If the upstream and downstream pressure are equal, the valve is open. If there’s a pressure drop, the valve is closed.

Yes, due to corrosion, debris, or mechanical failure. Applying lubricant, cleaning the valve, or replacing worn parts can help.

Knowing how to check if a valve is open or closed is fundamental for maintaining any fluid system efficiently and safely. By understanding the simple indicators and methods outlined, you can ensure your system operates smoothly and avoid common pitfalls.

For high-quality valves that stand the test of time, consider Lianke Valve, whose extensive range of products can meet your flow control needs.

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]