When choosing between valves for industrial applications, the decision often comes down to a comparison between globe valves and gate valves.

Both have their unique functions and characteristics, but the choice depends on specific factors like flow control, pressure regulation, and material suitability.

So, read on as this article provides a detailed comparison of these two types of valves, highlighting their key differences, working principles, and applications.

| Criteria | Globe Valve | Gate Valve |

| Design | Spherical body with a movable disc or plug | Vertical, flat gate that moves up and down |

| Flow Control | Ideal for throttling and flow regulation | Best for fully open or fully closed positions |

| Operation | Requires more force to operate due to flow resistance | Easier to operate as there is less resistance to the flow |

| Pressure Drop | Higher pressure drop due to complex design | Minimal pressure drop when fully open |

| Durability | Better suited for high-pressure applications | Performs well in low-pressure systems |

| Maintenance | Easier to maintain, fewer moving parts | Can be challenging to maintain and requires more attention |

| Common Materials | Often made from stainless steel for corrosion resistance | Common materials include stainless steel and flanged designs |

| Application | Used in industries requiring precise flow control | Used in applications where on/off control is needed |

| Valve Type | Pros | Cons |

| Globe Valve | Precise flow control: Ideal for throttling applications, allowing gradual flow regulation. | Higher pressure drop: Due to its flow path design, fluid experiences higher resistance, leading to a pressure drop. |

| Durable in high-pressure environments: Strong design suited for handling high-pressure and temperature changes. | More effort required to operate: Requires more force or a larger actuator to function due to flow resistance. | |

| Tight sealing: The perpendicular movement of the disc ensures a strong seal, minimizing leakage. | Costlier maintenance: The intricate internal components may require more frequent maintenance and replacement. | |

| Gate Valve | Minimal flow resistance: When fully open, the gate valve allows fluid to flow with minimal obstruction, ensuring efficient operation. | Limited throttling capabilities: Not suitable for throttling or flow control, as partial opening can damage the gate or seat. |

| Cost-effective for large diameter pipes: Suitable for systems with wide pipelines, often more economical than other valve types for large-scale operations. | Higher maintenance needs: The gate valve’s seat can wear out over time, especially when operating in systems with debris or solid particles, requiring regular maintenance. | |

| Simple operation: Gate valves are easy to operate, providing clear open and closed positions with minimal wear on internal parts. | Slow operation: The manual or actuator-driven movement of the gate can be slow, which may not be ideal for applications that require quick flow shutoff or control. |

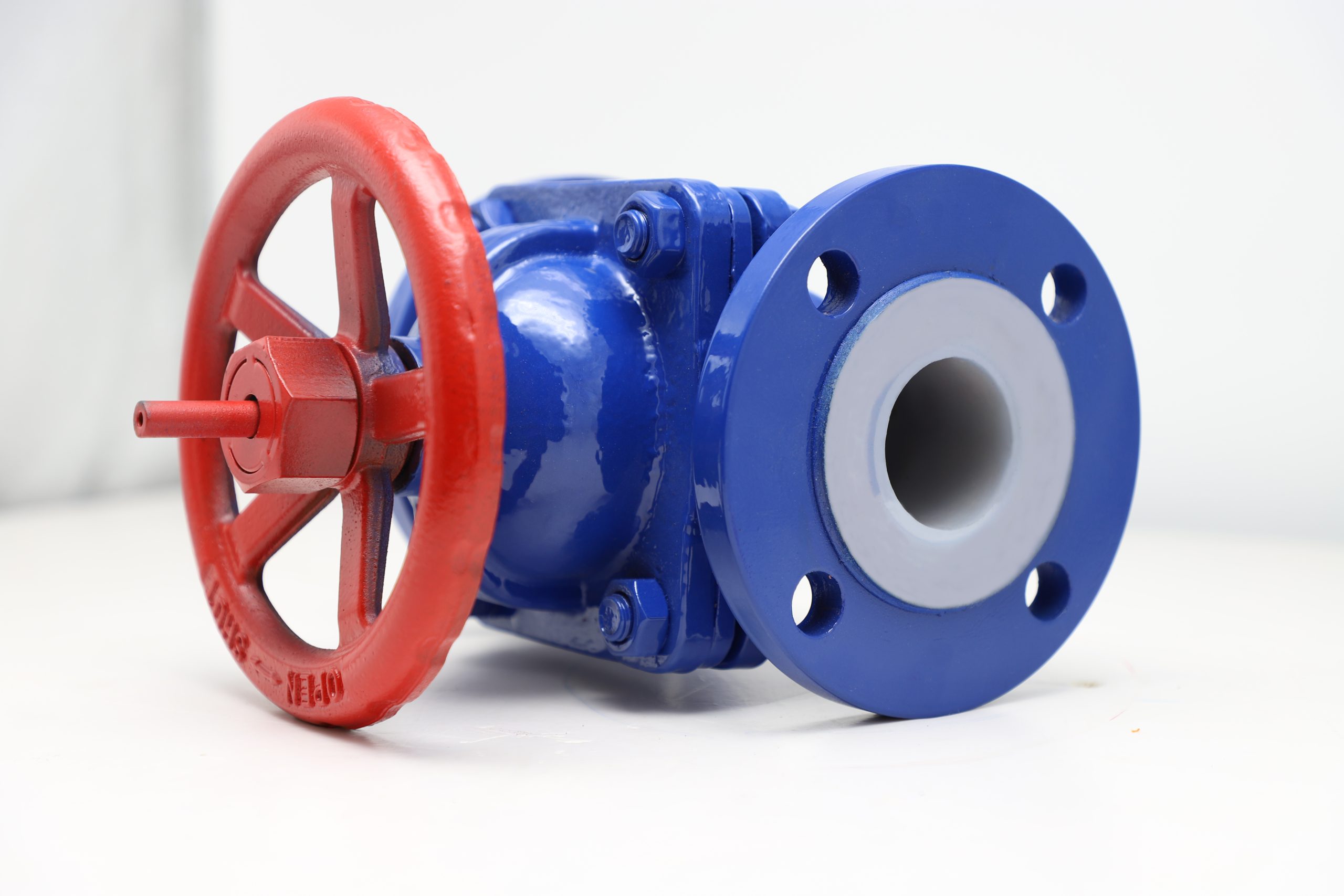

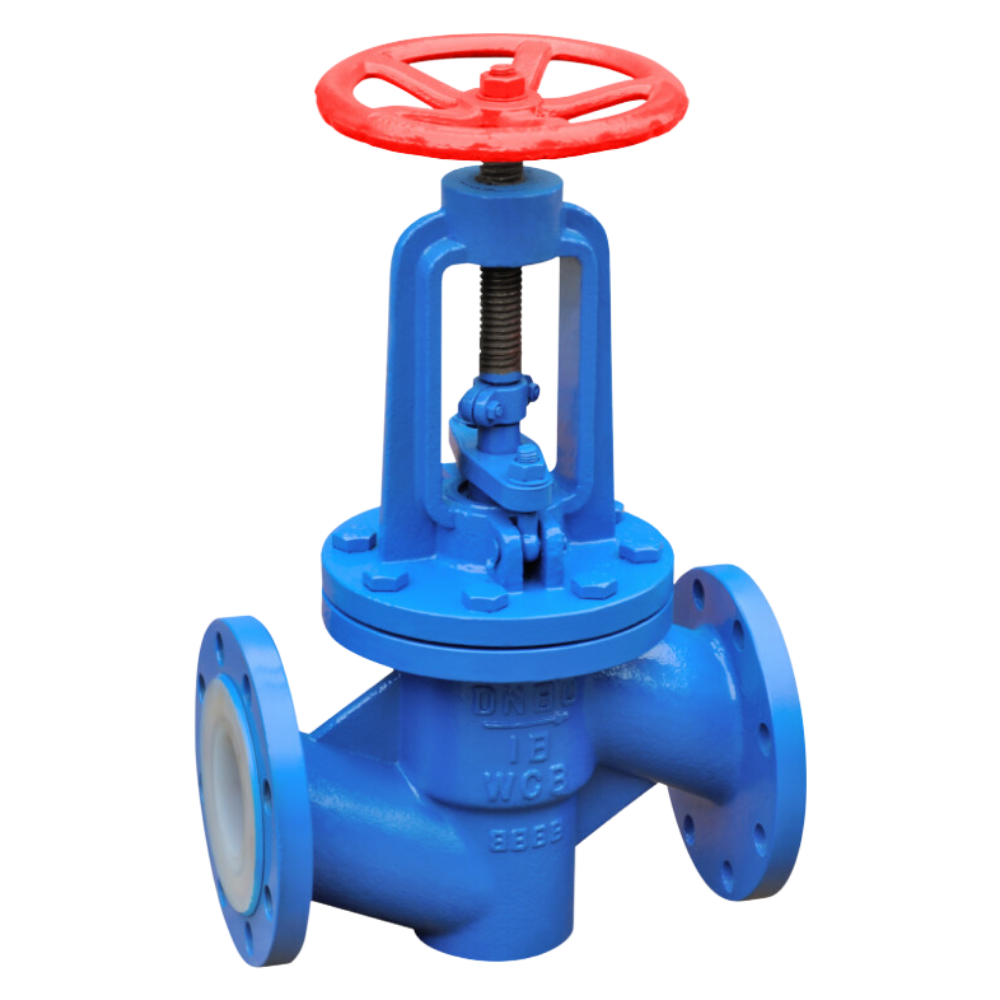

A globe valve is primarily designed for regulating or throttling flow in a pipeline. Its unique body shape, resembling a globe, gives it the name.

It is commonly used in situations where the control of fluid flow and pressure is crucial, making it ideal for applications in industries like oil and gas, water treatment, and chemical processing.

The globe valve operates by moving a disc or plug within the valve body, which opens or closes the flow path.

The valve seat is located in the middle of the valve body, and the movable disc or plug moves perpendicular to the flow of the fluid.

This design allows for precise control over the amount of fluid flowing through the valve — making it suitable for throttling purposes.

However, the intricate internal components create more flow resistance, which leads to a higher pressure drop compared to other valve types.

The body is the outer casing that holds all the internal parts together and connects to the pipeline.

The bonnet covers the valve stem and allows access for maintenance.

The disc, also known as the plug, is the part that moves up and down to control fluid flow.

The seat provides the surface on which the disc rests to form a seal when the valve is closed.

The stem connects the disc to the actuator or handwheel, allowing the operator to control the valve.

The handwheel or actuator is used to manually or automatically open and close the valve.

This is the most common type, offering a tight shutoff but with a high-pressure drop due to its complex design.

In this design, the valve changes the flow direction by 90 degrees, making it ideal for high-pressure applications.

This type offers less flow resistance compared to other globe valves, making it suitable for applications where pressure loss needs to be minimized.

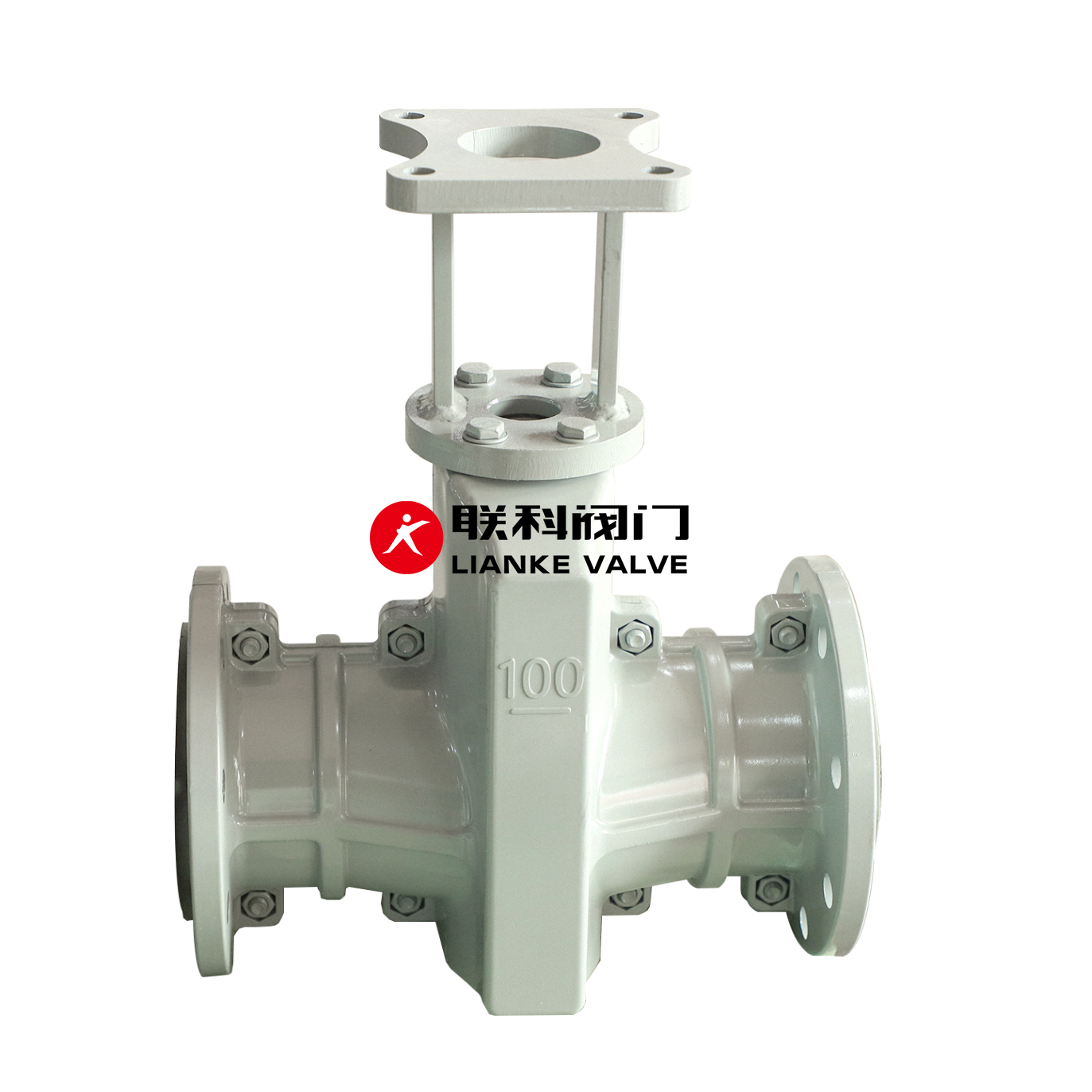

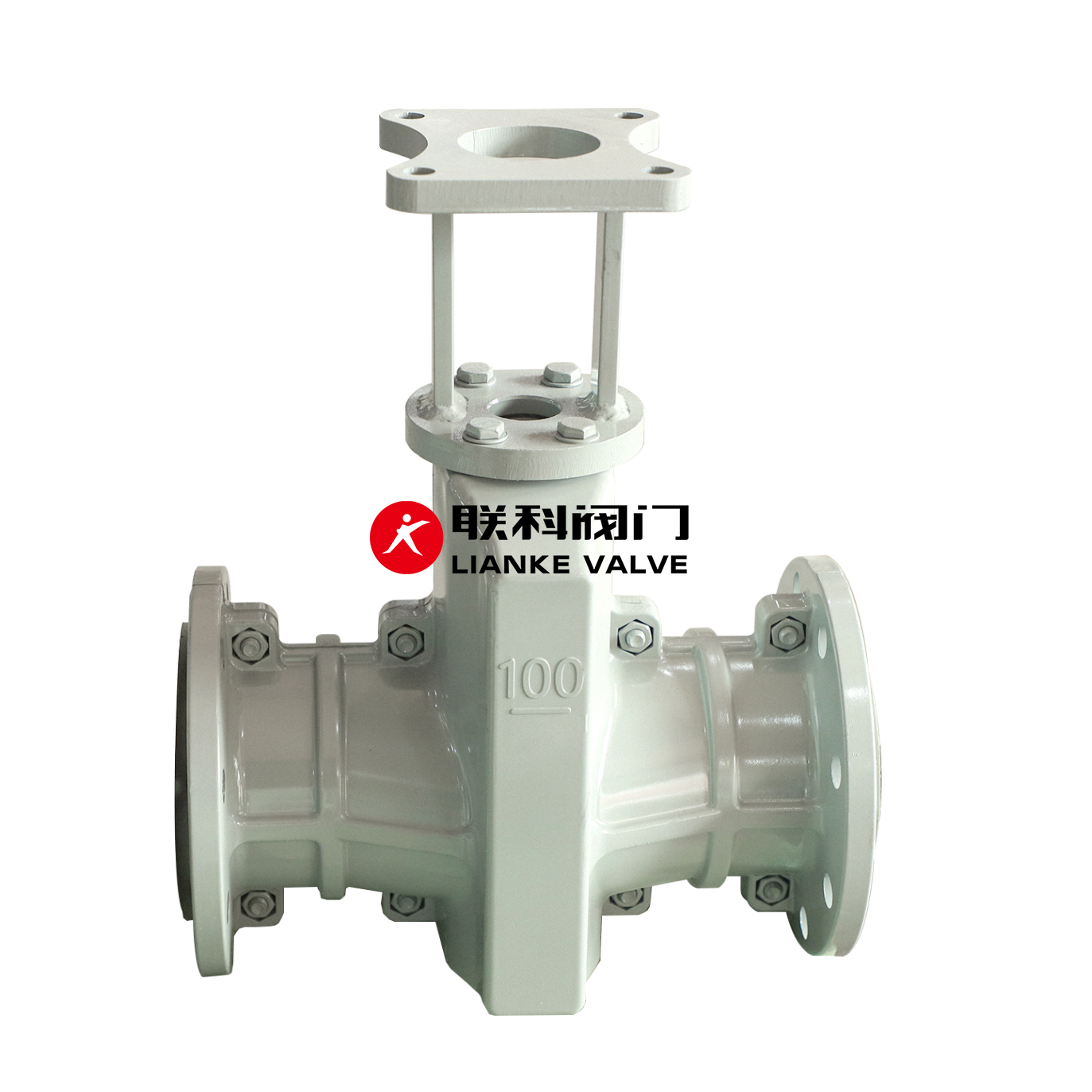

A gate valve is a type of valve designed for on/off control rather than flow regulation. It features a flat gate that moves vertically to block or allow the flow of fluid.

When fully open, the gate valve offers minimal flow resistance, making it a popular choice for applications that require unrestricted flow, such as water and gas pipelines.

Gate valves function by raising or lowering a gate within the valve body. When the gate is raised, fluid can flow freely; when it is lowered, the flow is completely blocked.

This simple design is effective for creating a tight seal when the valve is closed.

However, gate valves are not ideal for throttling, as partially open positions can lead to wear and tear on the gate, reducing the valve’s lifespan.

The body is the primary structure of the valve that houses the gate and other internal components.

The bonnet is the cover that encloses the stem and the gate, providing protection and allowing for easy maintenance access.

The gate is the part that moves up and down to block or allow fluid flow. It is usually made from stainless steel for durability.

The stem connects the gate to the handwheel or actuator, enabling control over the gate’s position.

The handwheel or actuator is the mechanism used to operate the valve, either manually or automatically.

The seat provides the sealing surface for the gate when the valve is in the closed position, ensuring a tight shutoff.

In this type, the stem rises when the valve is open, making it easy to see whether the valve is open or closed.

The stem does not rise in this design, making it more compact and suitable for limited-space installations.

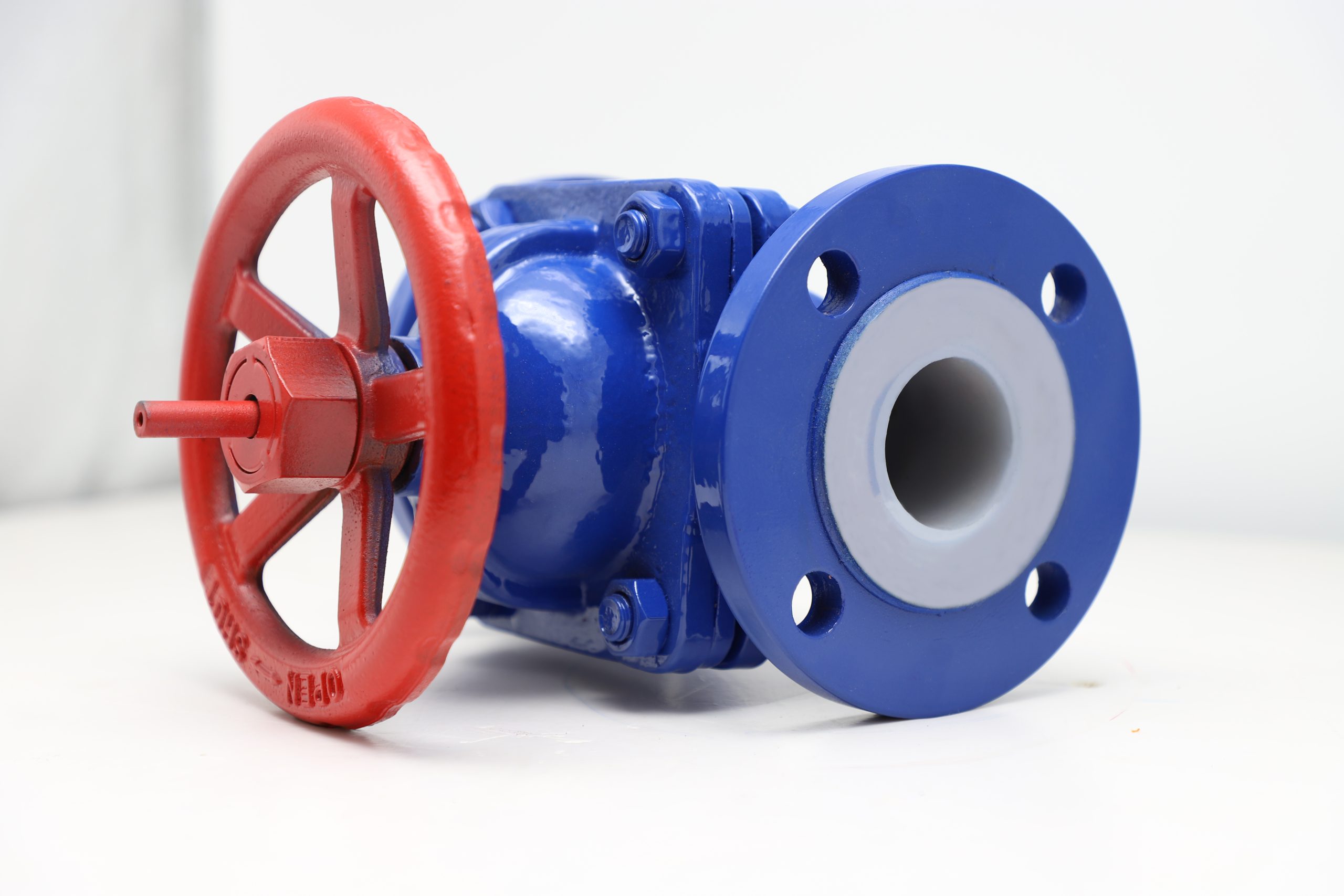

This type features flanged ends that allow easy attachment to pipelines, providing a reliable and durable connection.

A stainless steel gate valve is corrosion-resistant and ideal for harsh environments where rust and corrosion are concerns.

When it comes to sourcing high-quality valves, LIANKE stands out as one of China’s leading manufacturers.

The company specializes in producing both gate valves and globe valves for various industrial applications.

With years of experience in the field, LIANKE offers products like the fluorine-lined globe valve and stainless steel gate valve, which are known for durability and precision.

Contact us today!

Resources:

What is a Pinch Valve? A pinch valve is a control valve that utilizes pressurized air to manage fluid flow. Pinch valves are also referred to as squeeze valves or clamp valves. It is a cost-effective option due to its simplicity and low friction, making it resistant to clogging. Pinch valves find applications in on/off […]

From delivering purified water in a pharmaceutical lab to controlling the flow of corrosive chemicals in an industrial facility, diaphragm valves play a vital role in ensuring efficiency and safety. Known for their durability, tight sealing, and ability to handle diverse fluids, these valves are indispensable in many industries. Whether it’s a clean environment or […]

In industries like pharmaceuticals, food processing, and water treatment, ensuring the smooth flow of liquids, gases, or slurries is crucial to maintaining system efficiency and safety. Diaphragm valves stand out in these fields for their reliability, precision, and ability to handle a variety of substances, from clean water to corrosive chemicals. While they provide several […]

Diaphragm valves may not always be in the spotlight, but their role in controlling fluid flow is vital across various industries. These valves are designed with a flexible diaphragm that regulates the flow of liquids, gases, and semi-solids. From pharmaceuticals to water treatment, diaphragm valves provide precise control, tight shut-offs, and efficient fluid management. In […]