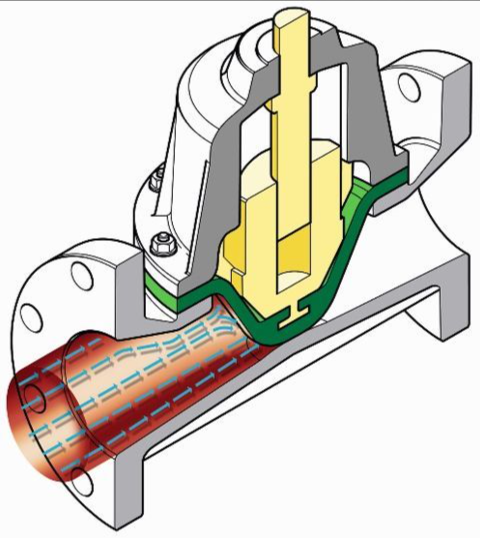

A diaphragm valve is a type of valve that uses a flexible diaphragm to control the flow of fluids. This valve is part of the linear motion family, which means the moving parts go in a straight line—not in circles like ball or butterfly valves. The elastomeric diaphragm in diaphragm valve is usually made of rubber or plastic and presses against a valve seat inside the diaphragm valve bodies to form a tight seal.

You can use diaphragm valves to control:

The fluid in a diaphragm valve system does not come into contact with the moving parts, such as the stem or actuator. This design ensures that the diaphragm valve remains clean and reduces the risk of damage.

Some diaphragm valves seal against a raised weir (a bump inside the valve), while others use a flat seat. Both designs help regulate or stop flow, depending on your needs.

DO YOU KNOW?

Using a flexible barrier to control fluid flow dates back to ancient times. Early civilizations used basic flexible barriers to manage water in irrigation systems and aqueducts.

These early diaphragm valves were made from natural materials like leather or animal skins. They created a seal against a seat, controlling water flow like modern diaphragm valves. Over time, the principle of using a flexible diaphragm to regulate flow has evolved.

A diaphragm valve works by moving a flexible membrane—called a diaphragm—up and down to control the flow of fluid (Diaphragm valves also called a membrane valve). This motion is linear, meaning it moves in a straight line rather than in circles like some other valves.

Here’s how it operates:

This movement can be powered by an actuator—a device that applies force. Actuators can be:

The diaphragm returns to its closed position either by its own flexibility or with the help of a spring inside the actuator.

In some designs, like weir diaphragm valves, the diaphragm presses against a raised surface (the weir). This lets you control the flow more precisely, which is helpful in low-flow or throttling applications.

A diaphragm valve has several key parts that work together to control fluid flow. Each piece plays a specific role in how the valve operates and how well it performs in different conditions.

Here are the main valve components:

Each part must be compatible with the fluid and environment to ensure the valve works safely and lasts longer.

Diaphragm valves come in different types based on how they seal. The two main types are:

Weir diaphragm valve has a raised barrier inside, called a weir. The diaphragm close and presses down on the weir to stop or control flow.

Straight Through Diaphragm Valves utilize a flat seat to ensure minimal obstruction. The diaphragm seals directly on the flat surface.

Other types include:

Diaphragm valves offer several practical benefits that make them useful in many industries. Their design helps solve common problems with fluid control.

1. Clean and Safe valve Operation

The diaphragm separates the fluid from the moving parts inside the valve. This stops the fluid from touching parts like the stem or actuator, which helps avoid contamination—especially important in food, pharmaceutical, and clean water systems.

2. Corrosion Resistance

Diaphragm valves can handle corrosive chemicals like acids and alkalis. This is because both the valve body and diaphragm can be made from special metals, plastics, or linings that resist chemical damage.

3. Leak-Proof Sealing

The flexible diaphragm forms a tight seal when it presses against the valve seat. This creates bubble-tight shutoff, even under high pressure or vacuum. It’s useful when working with hazardous or expensive fluids.

4. Handling semi Solid media and Slurries Well

These valves can deal with abrasive fluids and slurries (fluid with solid particles). The diaphragm bends around solids to help seal. Some designs also prevent clogging with a straight flow path.

5. Low Maintenance

There are fewer moving parts, so there’s less wear. The diaphragm is simple to replace without removing the whole valve from the pipe. Also, there’s no need for stem packing, which reduces leaks.

6. Good Flow Control

Weir valves offer more precise flow control, which is helpful in throttling (adjusting fluid flow rate). The linear motion of the diaphragm gives you direct control over how much fluid passes through.

While diaphragm valves offer many benefits, there are also some limitations you need to consider before choosing them for your system.

1. Pressure Limits

Standard diaphragm valves are best for moderate pressure systems—usually up to 300 psi (about 20 bar). For high-pressure applications, valves like ball or gate valves may be ideally suited.

2. Temperature Restrictions

The diaphragm material limits how hot (or cold) the valve can safely operate. Most diaphragms better to work in moderate pipeline temperatures: -40°F to 450°F (-40°C to 232°C). If your process involves higher temperatures, it could make diaphragm fails or weaken over time.

3. Diaphragm Wear

Since the diaphragm moves and touches the fluid directly, it can wear out, especially in systems with abrasive particles or frequent cycling. Straight-through types tend to wear faster because they require more flexing.

4. Limited Valve Sizes

Most diaphragm valves are available in sizes from ½ inch to 12 inches (DN 15–300). If your system needs larger valves, you may need to explore other types like butterfly or gate valves.

5. Drainage Issues

In weir-type valves, the raised weir can trap fluid, making full drainage difficult. This can be a problem in batch processes or when switching between fluids.

6. Slower Manual Operation

Manual diaphragm valves often need multiple turns to open or close fully. This makes them slower than quick-action valves like ball or butterfly valves. For fast shut-off, consider automated diaphragm valves

Choosin’ the right diaphragm valve is mighty important. You need to think about a lot of things to make sure it works right and lasts long. Let’s break it down:

What do you need the valve to do? Think about what you’re controllin’ and how it fits into the whole system.

Fluid Control: How much liquid or gas do you need to control? What’s its speed? Is it thick? This helps pick a valve that can handle the fluid flow.

Industry Matters: Different industries have different rules. Food and medicine need CLEAN valves. Chemical plants need valves that resist BAD stuff.

Types of Bodies: There are different shapes, like straight, angled, and T-shaped. Each one works best for different jobs.

Material: The valve body needs to handle the fluid. Stainless steel, plastics, and special alloys are common. If the fluid is corrosive, pick other materials that RESISTS it.

Parts: Know the parts! Valve Body, bonnet, diaphragm, valve stem, actuator. Each part matters for how the valve works.

EPDM vs. PTFE: EPDM rubber is good for water. PTFE (Teflon) handles STRONG chemicals. Pick the right one!

What’s the fluid? Make sure the diaphragm can handle the fluid. Otherwise, it’ll break down fast!

Temperature and Pressure ratings: Hot and high-pressure can mess with the diaphragm. Pick a material that can take the heat and pressure.

Types: Manual (hand), electric, air-powered (pneumatic), hydraulic. Pick one that fits your needs.

Air Pressure: If you use air, make sure the pressure is right. Too low, and the valve won’t work. Too high, and it can break!

Special Features: Some actuators have extra features for better control.

Quality Matters: Selecting high-grade materials ensures durability, reducing wear and tear, and enhancing valve performance over time.

Easy to Fix: Opt for valves with simple disassembly and repair processes, minimizing downtime and maintenance costs.

Whether you’re dealing with corrosive fluids, slurries, or hygienic processes, diaphragm valves offer precise flow control and low maintenance.

For those seeking durability and performance, rubber-lined diaphragm valves from Lianke are a smart choice. With decades of experience and a strong product range, Lianke delivers solutions built to last. If you’re ready to upgrade or start a project, explore Lianke’s diaphragm valves and contact us today to find the right valve for your application.

Diaphragm Valves: Types, Uses, Features and Benefits

ANSI Class Ratings for Y strainer flanges tell you how much pressure and temperature the flange can handle. These ratings help you choose the right flange material and design to keep your piping system safe and efficient. If you’re installing or replacing a Y strainer in a pipeline, understanding ANSI ratings isn’t optional—it’s essential. Choosing […]

To choose the right wye strainer, you need to understand mesh and screen size. These determine what particles your system can filter out. The finer the mesh, the smaller the particles it catches. This guide explains how to select the correct strainer mesh size, use a mesh size chart, and compare mesh size vs micron […]

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]