In industrial systems, check valves are critical for preventing backflow, protecting equipment, and maintaining process efficiency. However, improper installation can lead to premature wear, leaks, or even system failure. For engineers, mechanics, and technicians, understanding the technical nuances of check valve installation is essential. This guide breaks down key considerations, supported by industry standards and data, to ensure your valves perform reliably under demanding conditions.

Check valves are simple devices, but their effectiveness hinges on precise installation. Here’s what you need to prioritize:

Position check valves where they’re easily accessible for inspection and maintenance. For example, isolating a pipeline section during repairs requires valves to be strategically placed—ideally near pumps, elbows, or system branches. According to Rangeline, valves installed too close to bends or fittings risk turbulence, which accelerates wear.

Key Rule:

This minimizes turbulent flow, reducing stress on the valve disc and seat.

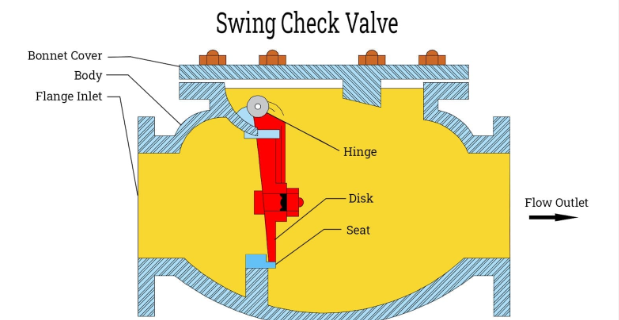

Check valves must align with the system’s flow direction. The valve body typically has an arrow indicating the correct orientation. Gravity-dependent valves (e.g., swing check valves) require vertical installation with flow moving upward. In contrast, silent spring-loaded check valves work in any orientation, including horizontal lines (Milwaukee Valve).

Pro Tip: After installation, verify the valve opens freely in the flow direction. A stuck disc can cause dangerous pressure surges.

The valve’s connection method impacts durability and leak resistance. Below is a comparison of common types:

| Connection Type | Best Applications | Pressure Rating | Ease of Maintenance |

|---|---|---|---|

| Threaded | Low-pressure systems (e.g., water lines) | Up to 150 psi | Simple, but prone to leaks if overtightened |

| Flanged | High-pressure, high-temperature systems | 150–2500 psi | Easy disassembly, requires precise alignment |

| Welded | Permanent, high-integrity systems (e.g., chemical plants) | 2500+ psi | Permanent; no disassembly possible |

Source: Rangeline, Allied Valve

Flanged connections are ideal for systems requiring frequent maintenance, while welded joints suit corrosive or high-pressure environments.

Follow these steps to ensure a secure, leak-free installation:

Valve materials must withstand the fluid’s chemical properties and temperature. For example:

Always cross-reference the valve’s pressure-temperature rating with the system’s operating conditions (Tameson).

Over-tightening threaded connections can strip threads or crack the valve body. For NPT threads, tighten until snug, then add 1/4 to 1/2 turn with a wrench.

Proper check valve installation isn’t just about following steps—it’s about understanding how design, placement, and materials impact long-term performance. By adhering to straight-pipe guidelines, choosing the right connection type, and verifying flow direction, you’ll minimize downtime and maintenance costs.

What is A Diaphragm Valve? A diaphragm valve is a type of valve that uses a flexible diaphragm to control the flow of fluids. This valve is part of the linear motion family, which means the moving parts go in a straight line—not in circles like ball or butterfly valves. The elastomeric diaphragm in diaphragm […]

Your valve is leaking because something has gone wrong with its sealing system. Maybe the seals are worn out after years of service. Perhaps debris is stuck between critical surfaces. Or it could be that improper installation created misalignment from the beginning. These common problems prevent the valve from achieving perfect closure when you need […]

Valve Flow Coefficient (Cv) is a measure of a valve’s capacity to allow liquid or gas to flow through it. It’s technically defined as “the volume of water at 60°F (in US gallons) that will flow through a valve per minute with a pressure drop of 1 psi across the valve.” You calculate Cv by […]

When selecting the right valve for industrial applications, understanding pressure and temperature ratings is crucial. Many professionals in the field struggle with terms like Class, Rating, and PN, which can lead to costly mistakes if misunderstood. This guide will help you understand these concepts so you can select valves with confidence. What Do Pressure Units […]