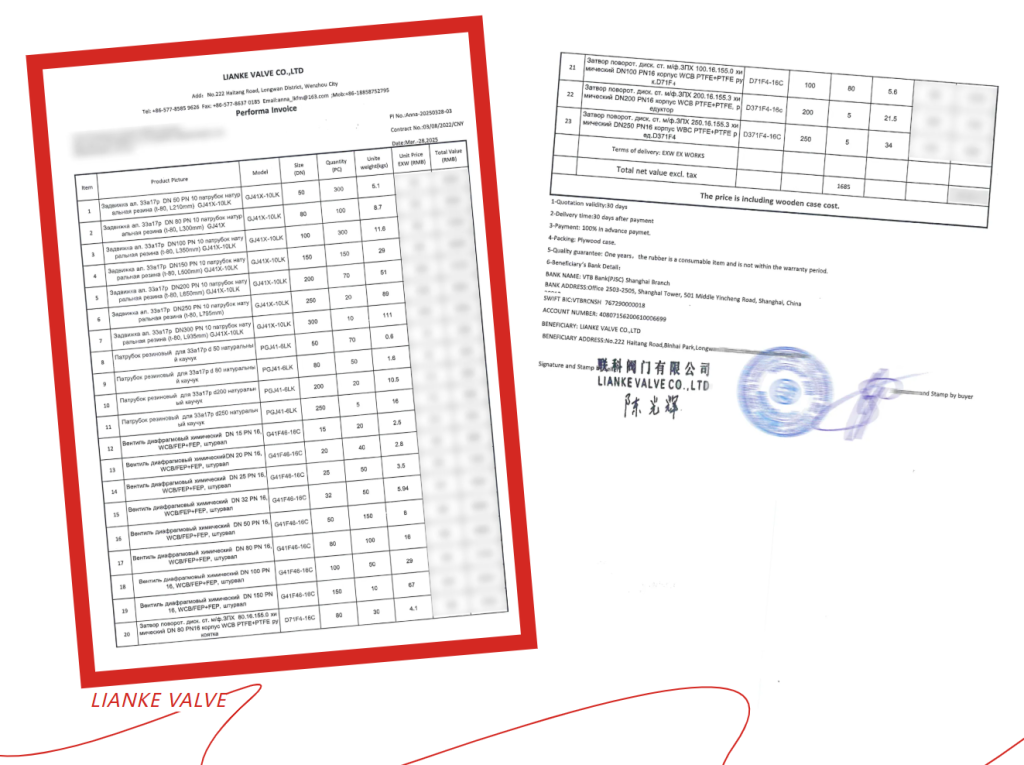

Our international business continues to thrive as we have recently signed a significant export order involving 1,685 units of pinch valves and fluorine-lined valves.

This successful deal is not only a testament to the long-term trust between both parties, but also a strong endorsement of Lianke’s reputation and brand strength in the global market.

As a national high-tech enterprise with nearly 40 years of expertise in the design and manufacturing of pinch valves, industrial strainers, and PTFE/PFA-lined valves, Lianke has always adhered to the core philosophy of “Craftsmanship Quality, Innovative Service.”

Our products are widely recognized by customers worldwide for their:

The client involved in this deal is a long-term partner who has chosen Lianke repeatedly, a strong reflection of the trust and satisfaction we earn from the international market.

This newly secured order is not only a recognition of Lianke’s product quality, but also a result of mutual trust and long-standing collaboration.

Looking ahead, we will continue to:

All in support of helping our customers achieve sustainable business growth.

We warmly welcome more partners from around the world to join us and seize opportunities for shared success!

Choosing the right basket strainer for your system comes down to understanding filtration size, strainer mesh, and how these elements fit into your specific piping setup. Whether you’re working in chemical processing, food production, water treatment, or HVAC, the right strainer ensures system protection, flow efficiency, and long-term equipment performance. This article will help you […]

Installing, operating, and maintaining a basket strainer properly ensures optimal system performance, protects downstream equipment, and extends the life of your filtration system. Whether used in chemical processing, HVAC, food production, or water treatment systems, basket strainers are essential components for removing solid particles from fluids. In this article, we’ll break down the complete lifecycle […]

Valve testing ensures that industrial valves meet strict performance, safety, and durability standards before they are installed in real-world systems. This process verifies that valves operate reliably under pressure, prevent leaks, and perform in extreme conditions such as high temperature or cryogenic environments. Whether it’s a valve leak test or a gas valve test, the […]

The most effective way to resolve pinch valve issues is to identify the root cause early—whether it’s sleeve wear, actuation failure, or leaks—and apply targeted troubleshooting steps to restore performance. Pinch valves are favored for their durability and simplicity in handling slurries, abrasive materials, and corrosive fluids. But like any component, they can develop problems […]