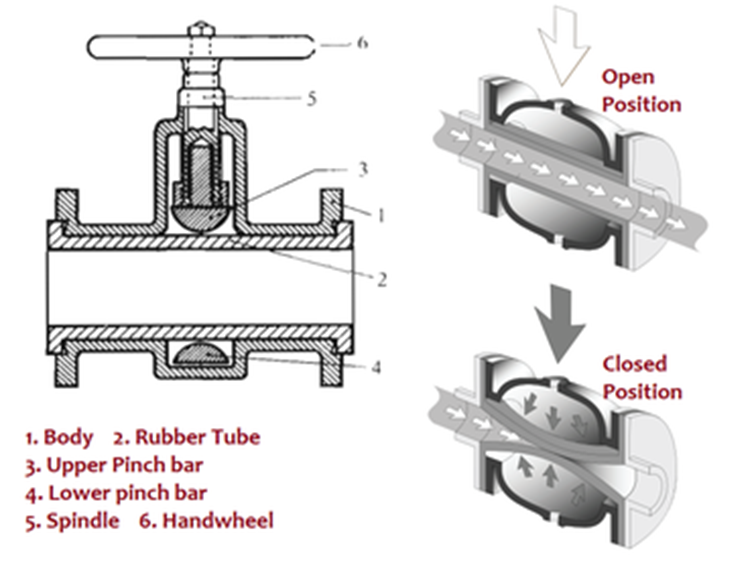

An air pinch valve with flange is a flow-control device that uses compressed air (4–8 bar) to open or close a rubber sleeve, regulating the passage of abrasive, corrosive, or viscous media. The flange connection ensures secure pipeline mounting, complying with standards like DIN EN 1092 or ANSI B16.5. This guide explains its design, materials, and industrial applications without promotional bias.

| Elastomer | Temperature Range | Best For |

| Natural Rubber (NR) | -40°C to +80°C | Abrasive slurries, mining tailings. |

| EPDM | -30°C to +150°C | Steam, acids (pH 3–12). |

| Viton (FKM) | -20°C to +200°C | Oils, solvents, chlorinated chemicals. |

| NBR | -30°C to +100°C | Fuels, oils, non-polar fluids. |

| Standard | Pressure Rating | Common Use Cases |

| DIN EN 1092 (PN10/16) | 10–16 bar | European water treatment, chemical plants. |

| ANSI B16.5 (150#) | 19.6 bar | U.S. oil/gas, high-pressure slurry systems. |

| Feature | Pinch Valve | Gate Valve | Ball Valve |

| Clogging Risk | None (full bore) | High (gate grooves) | Moderate (ball cavity) |

| Maintenance | Replace sleeve only | Stem/packing repairs | Seat/ball replacement |

| Abrasion Resistance | High (sleeve absorbs wear) | Low (metal parts wear) | Moderate |

Q: How long do air pinch valve sleeves last?

A: 1–5 years, depending on abrasion and chemical exposure. Mining slurries wear sleeves faster than water.

Q: Can air pinch valve sleeve handle high temperatures?

A: Yes. EPDM sleeves withstand +150°C; Viton handles +200°C.

Q: What’s the maximum pressure rating for air pinch valve?

A: DN25–DN150: 6 bar; DN200: 4 bar; DN250–DN450: 3 bar.

Q: Can air pinch valve work with viscous fluids?

A: Yes. Full-bore design prevents clogging in adhesives or sludge.

Air pinch valves with flanges offer reliable flow control in harsh environments, with minimal maintenance and no flow obstruction. Selecting the right sleeve material and flange standard ensures longevity in applications from mining to food processing.

Your valve is leaking because something has gone wrong with its sealing system. Maybe the seals are worn out after years of service. Perhaps debris is stuck between critical surfaces. Or it could be that improper installation created misalignment from the beginning. These common problems prevent the valve from achieving perfect closure when you need […]

Valve Flow Coefficient (Cv) is a measure of a valve’s capacity to allow liquid or gas to flow through it. It’s technically defined as “the volume of water at 60°F (in US gallons) that will flow through a valve per minute with a pressure drop of 1 psi across the valve.” You calculate Cv by […]

When selecting the right valve for industrial applications, understanding pressure and temperature ratings is crucial. Many professionals in the field struggle with terms like Class, Rating, and PN, which can lead to costly mistakes if misunderstood. This guide will help you understand these concepts so you can select valves with confidence. What Do Pressure Units […]

The main difference between plastic and elastomer comes down to flexibility and shape retention. Plastics are rigid or semi-rigid. Once they bend or break, they don’t bounce back. Elastomers are flexible. They stretch, twist, or compress and return to their original shape. Below, we’ll take a closer look at how these materials differ and the conditions […]