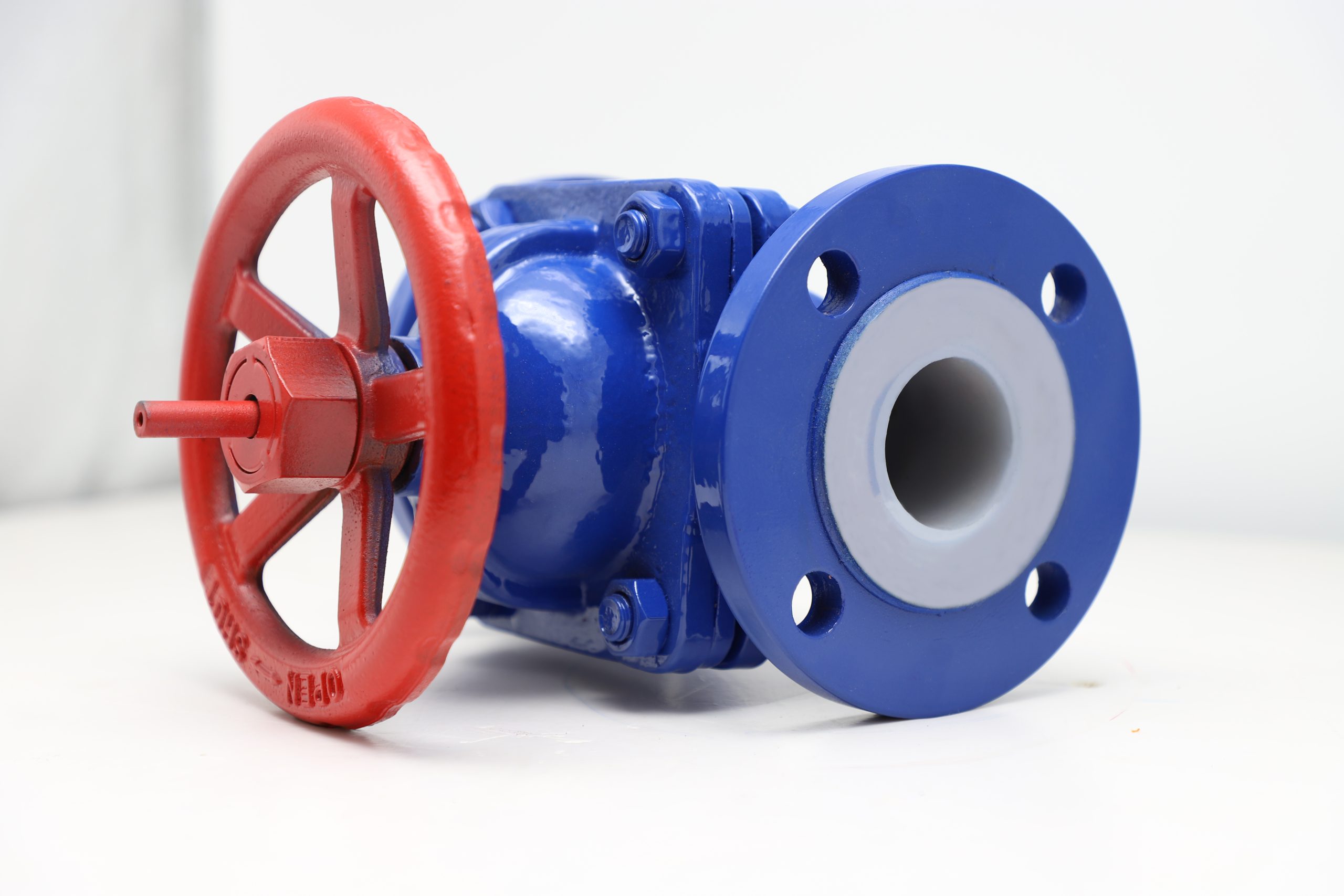

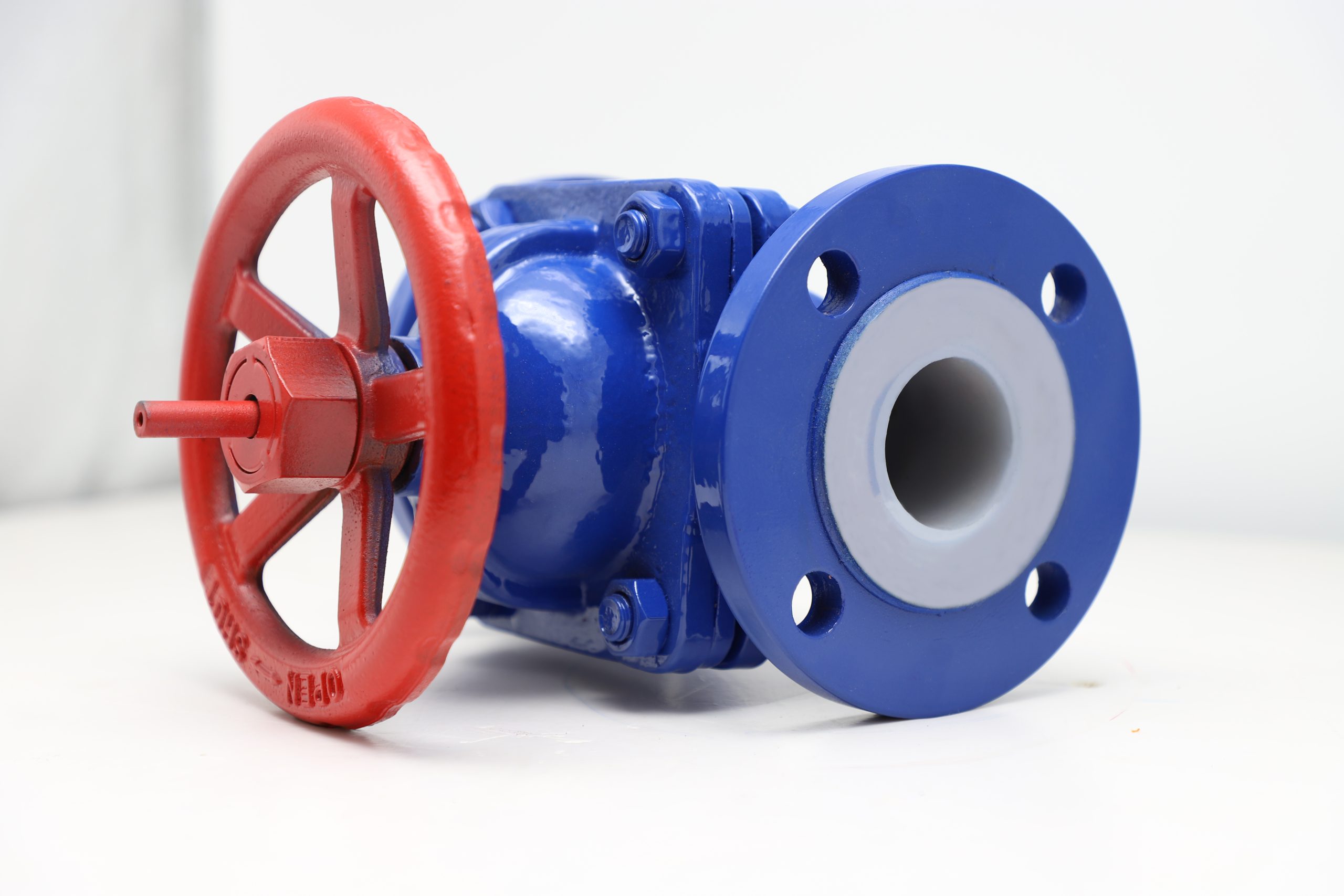

From delivering purified water in a pharmaceutical lab to controlling the flow of corrosive chemicals in an industrial facility, diaphragm valves play a vital role in ensuring efficiency and safety.

Known for their durability, tight sealing, and ability to handle diverse fluids, these valves are indispensable in many industries.

Whether it’s a clean environment or a challenging, abrasive one, diaphragm valves step up to provide precision and reliability.

Let’s dive into the key applications where diaphragm valves shine and see why they are so widely trusted.

In environments where cleanliness and sterility are paramount, diaphragm valves are a top choice.

Their design prevents contamination by isolating the fluid from the valve mechanism, making them ideal for transporting purified water, chemicals, and other sensitive fluids.

These valves are also compatible with CIP (Clean-In-Place) and SIP (Steam-In-Place) systems, which ensure that manufacturing processes meet stringent hygiene standards.

From producing vaccines to manufacturing essential medicines, diaphragm valves help maintain the integrity of operations in these critical fields.

Diaphragm valves are often used in the production of beverages, dairy products, and processed foods.

Their smooth, crevice-free interior design prevents the buildup of residue, ensuring compliance with food safety regulations.

Whether it’s controlling the flow of syrups, milk, or carbonated water, diaphragm valves deliver precision and reliability.

Additionally, their ability to withstand regular cleaning and sterilization cycles makes them a staple in food processing plants.

Managing the flow of water in treatment facilities is no small task, and diaphragm valves are instrumental in ensuring smooth operations.

These valves are used to regulate water flow, isolate sections of the system, and handle the dosing of treatment chemicals like chlorine.

Their corrosion resistance and tight sealing capabilities make them suitable for handling both potable water and wastewater, ensuring safe and efficient water processing.

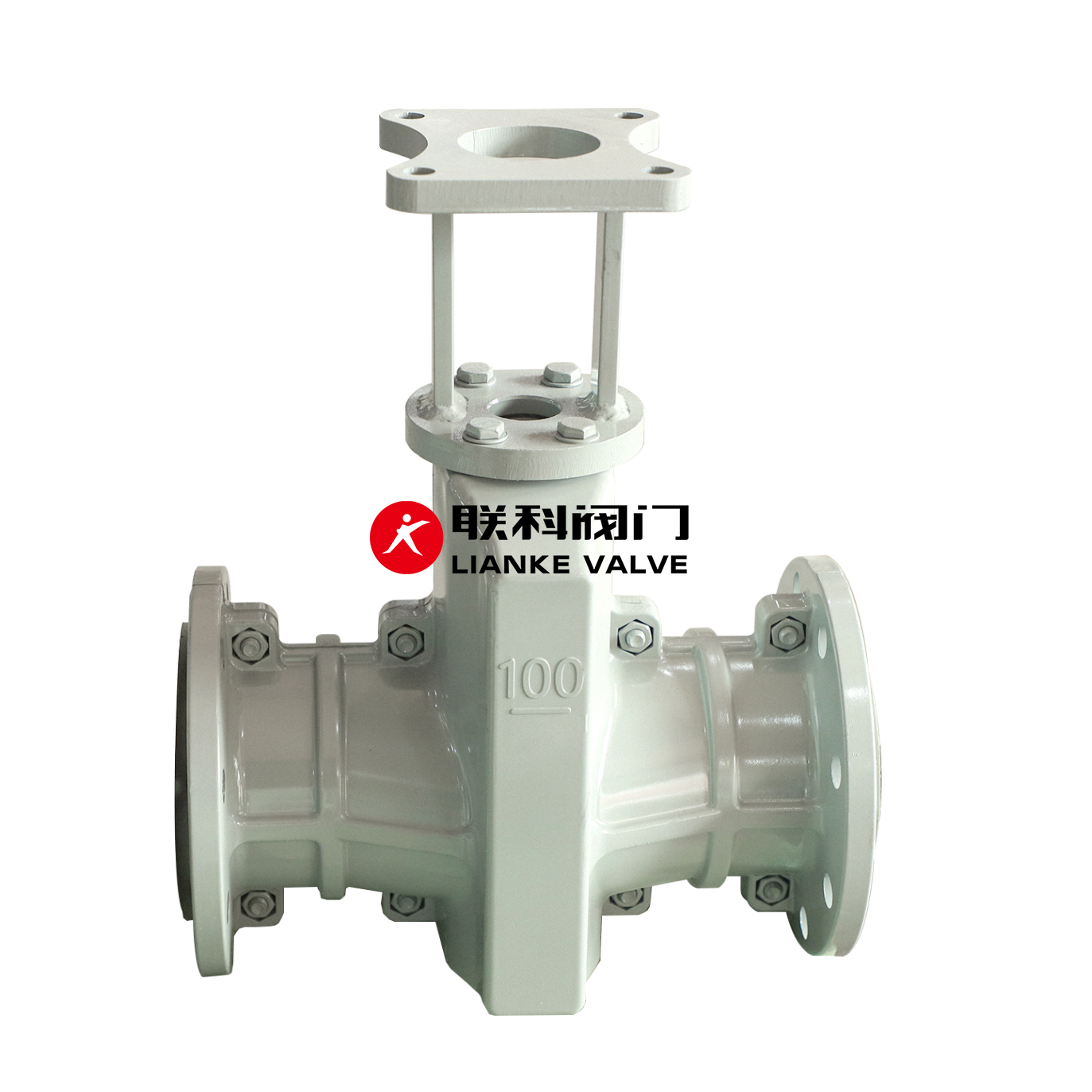

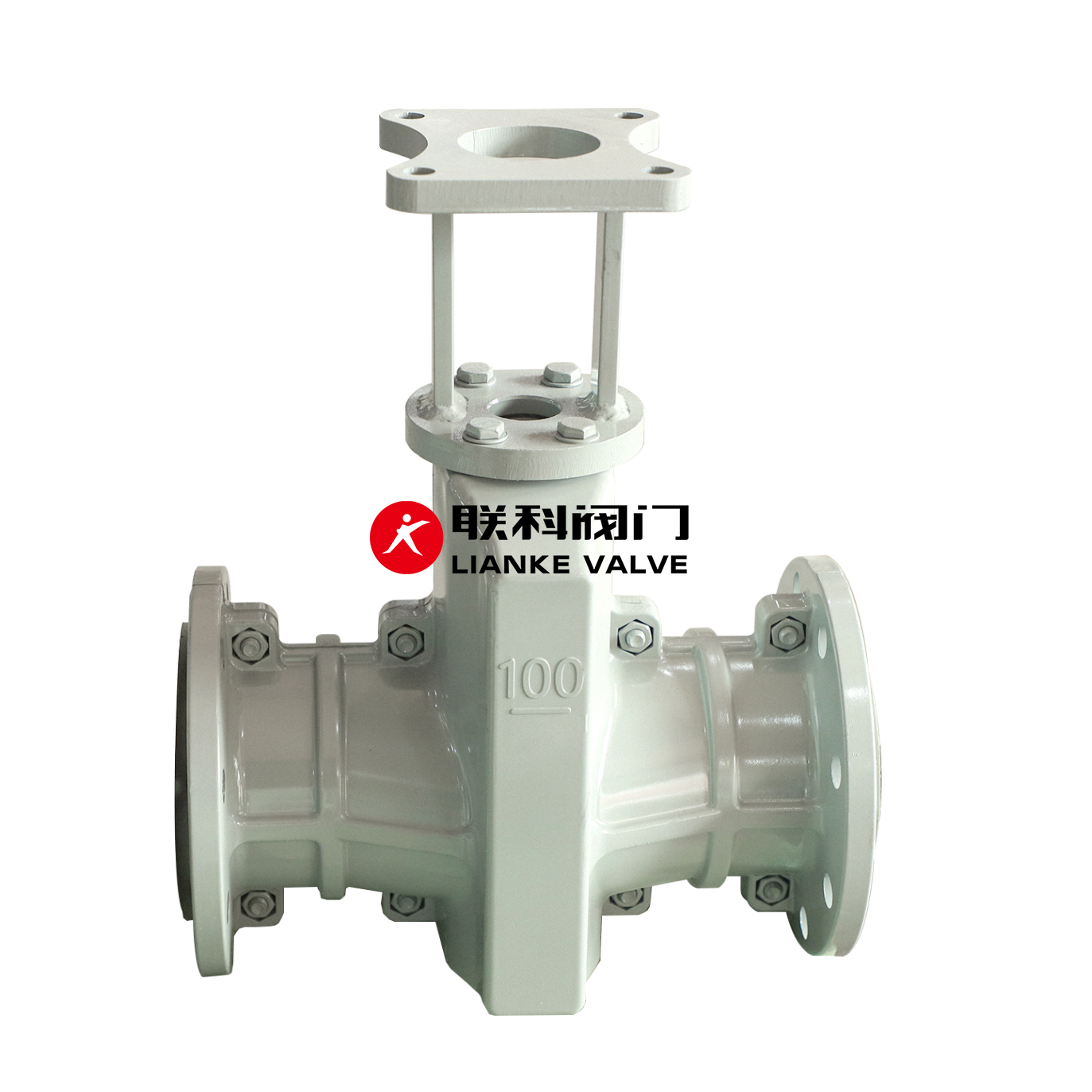

In the chemical industry, handling aggressive and corrosive fluids requires valves that can withstand tough conditions.

Diaphragm valves, especially those with rubber or PTFE linings, are specifically designed for this purpose.

They can safely control the flow of acids, alkalis, solvents, and other hazardous substances.

Their ability to provide precise flow control while protecting workers and equipment from leaks makes them an essential tool in chemical processing facilities.

Mining operations often involve abrasive slurries and other challenging materials, and diaphragm valves are up to the task.

Their robust construction allows them to handle highly viscous and abrasive fluids without significant wear and tear.

Whether used in slurry pipelines, mineral extraction processes, or tailings management, these valves contribute to the efficiency and longevity of mining equipment.

In the production of paper and related products, diaphragm valves are used to control the flow of chemicals, dyes, and water.

Their ability to handle viscous fluids and resist chemical corrosion makes them an ideal choice for these demanding applications.

By ensuring smooth flow control, diaphragm valves help maintain the quality and consistency of the end product.

In power plants, particularly those that use steam turbines, diaphragm valves play a critical role in controlling cooling water, steam, and chemical additives.

Their ability to perform under high temperatures and challenging conditions makes them suitable for use in both conventional and renewable power generation facilities.

Their durability also ensures uninterrupted operations, reducing downtime in these high-demand environments.

Diaphragm valves are versatile and reliable, proving their worth in industries ranging from pharmaceuticals to mining.

Their adaptability to diverse environments, coupled with their ability to provide precise flow control and leak prevention, makes them an essential tool in modern industrial processes.

Whether the need is for sterility, corrosion resistance, or durability, diaphragm valves deliver exceptional performance across a variety of applications.

Diaphragm Valves: Types, Uses, Features and Benefits

What is a Pinch Valve? A pinch valve is a control valve that utilizes pressurized air to manage fluid flow. Pinch valves are also referred to as squeeze valves or clamp valves. It is a cost-effective option due to its simplicity and low friction, making it resistant to clogging. Pinch valves find applications in on/off […]

From delivering purified water in a pharmaceutical lab to controlling the flow of corrosive chemicals in an industrial facility, diaphragm valves play a vital role in ensuring efficiency and safety. Known for their durability, tight sealing, and ability to handle diverse fluids, these valves are indispensable in many industries. Whether it’s a clean environment or […]

In industries like pharmaceuticals, food processing, and water treatment, ensuring the smooth flow of liquids, gases, or slurries is crucial to maintaining system efficiency and safety. Diaphragm valves stand out in these fields for their reliability, precision, and ability to handle a variety of substances, from clean water to corrosive chemicals. While they provide several […]

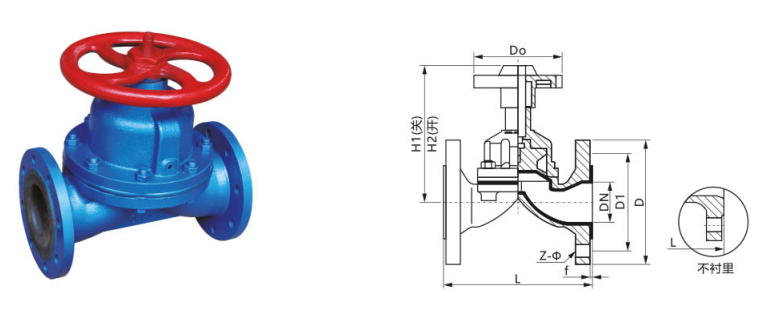

Diaphragm valves may not always be in the spotlight, but their role in controlling fluid flow is vital across various industries. These valves are designed with a flexible diaphragm that regulates the flow of liquids, gases, and semi-solids. From pharmaceuticals to water treatment, diaphragm valves provide precise control, tight shut-offs, and efficient fluid management. In […]